Harvesting method of Dunaliella salina

A Dunaliella salina, harvesting method technology, applied in the direction of single-celled algae, isolated microorganisms, etc., can solve the problems of affecting the economic benefits of enterprises, large damage to algae cells, and low harvesting efficiency, and achieve a large amount of one-time processing and damage The effect of extreme degree and improvement of recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

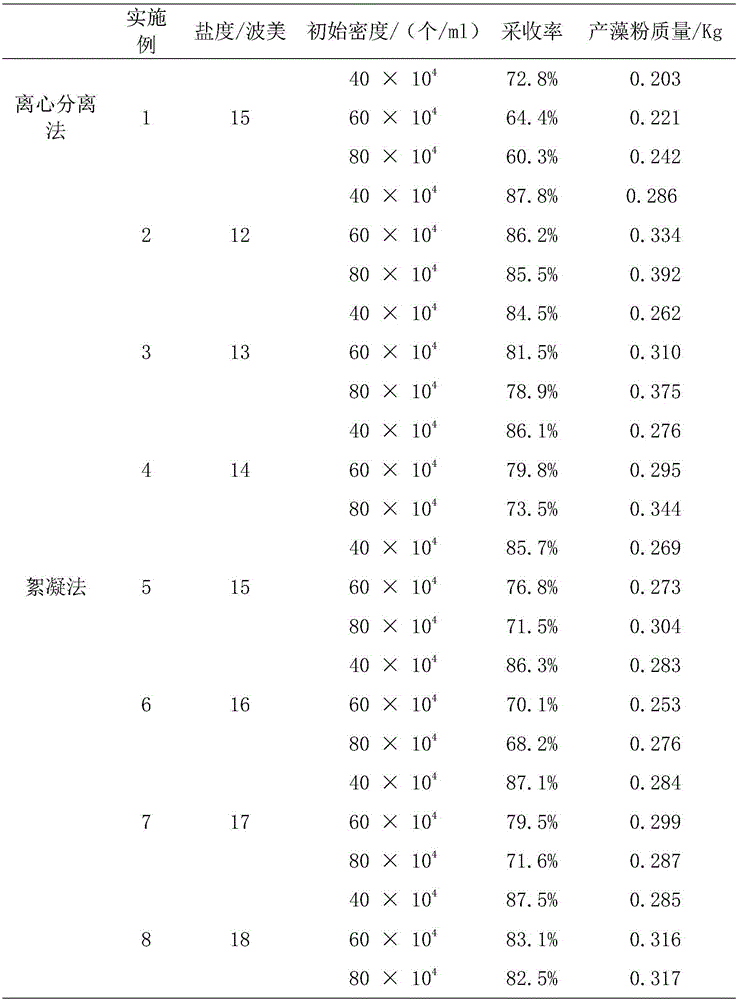

[0069] Embodiment 1: The initial salinity of harvesting by centrifugal separation is 15 Dunaliella salina experiment

[0070] Experimental materials and equipment: necessary drainage pipes such as water pumps, tube centrifuges, blood counting boards, etc.

[0071] Experimental conditions: normal temperature and pressure

[0072] Algae fluid volume: 1.8m for each experimental treatment 3

[0073] The initial cell number of algal liquid: 40×104 cells / ml, 60×104 cells / ml, 80×104 cells / ml in the three tests of 1#, 2# and 3# respectively

[0074] Reaction time: 1.8 hours per test

[0075] Experimental results:

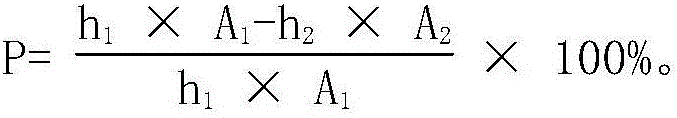

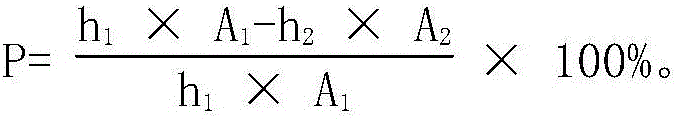

[0076] ①. The recovery efficiency is P1#=72.8%, P2#=64.4%, P3#=60.3%;

[0077] ②. The quality of algae powder produced is: M1#=0.203㎏, M2#=0.221㎏, M3#=0.242㎏

Embodiment 2

[0078] Example 2: Flocculation experiment of algae liquid with an initial salinity of 12

[0079] Experimental materials and equipment: the volume is 2m 3 3 vats (up and down with multiple drainage outlets) labeled 1#, 2#, 3#, analytical grade NaOH (≥99%), scales, blood counting boards and necessary drainage pipe devices

[0080] Experimental conditions: normal temperature and pressure

[0081] Algae liquid volume: 1.8m in each vat 3 ;

[0082] The initial cell number of algae liquid: 40×104 cells / ml, 60×104 cells / ml, 80×104 cells / ml in 1#, 2#, 3# tanks respectively

[0083] Added NaOH quality: 3.6kg per vat

[0084] Response time: 4 hours

[0085] Experimental results:

[0086] ① Floating or settling conditions: the algal flocculation in the three vats all settled;

[0087] ②. Recovery factor: P1#=87.8%, P2#=86.2%, P3#=85.5%;

[0088] ③. Quality of algae powder: M1#=0.286㎏, M2#=0.334㎏, M3#=0.392㎏

Embodiment 3

[0089] Example 3: Flocculation experiment of algae liquid with an initial salinity of 13

[0090] Experimental material and equipment: same as embodiment 2

[0091] Experimental conditions: close to Example 2.

[0092] Experimental results:

[0093] ① Floating or settling conditions: the algal flocculation in the three vats all settled;

[0094] ②. Recovery factor: P1#=84.5%, P2#=81.5%, P3#=78.9%;

[0095] ③. Quality of algae powder: M1#=0.262㎏, M2#=0.310㎏, M3#=0.375㎏

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com