Method for preparing electrode material of lithium-ion-mixed capacitor and application thereof

A technology for hybrid capacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitors, and hybrid/electric double-layer capacitors, can solve the problems of cumbersome steps, high cost, unsuitable for large-scale industrial production, etc. Easy, high energy density and power density, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

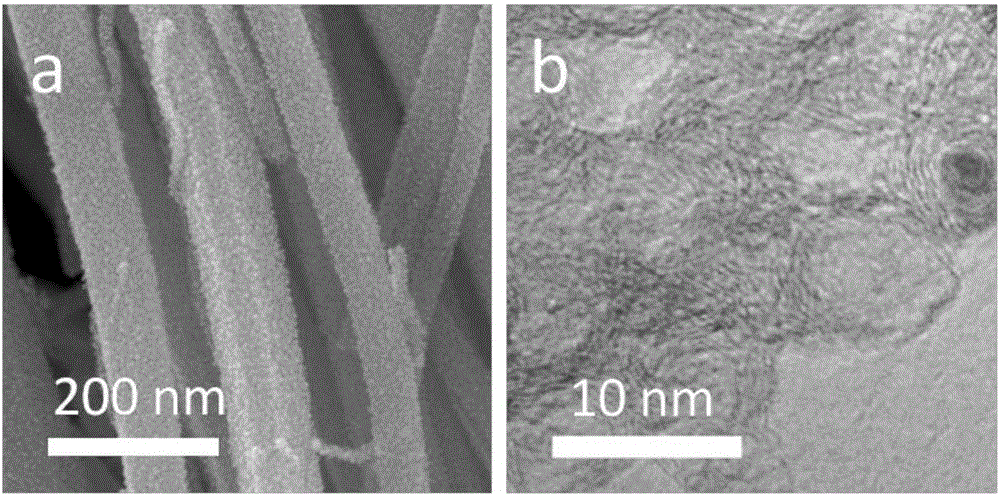

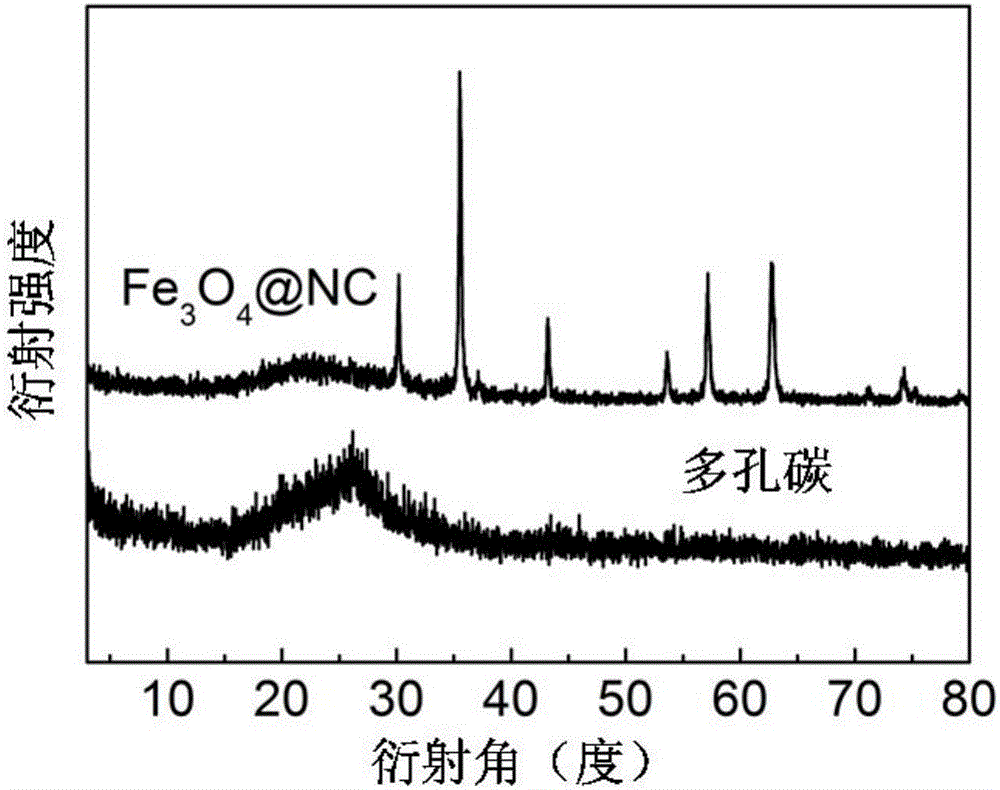

[0026] A kind of preparation method of lithium ion hybrid capacitor electrode material, described lithium ion hybrid capacitor electrode material comprises negative electrode material Fe 3 o 4 @C and positive electrode material porous carbon, the steps are as follows:

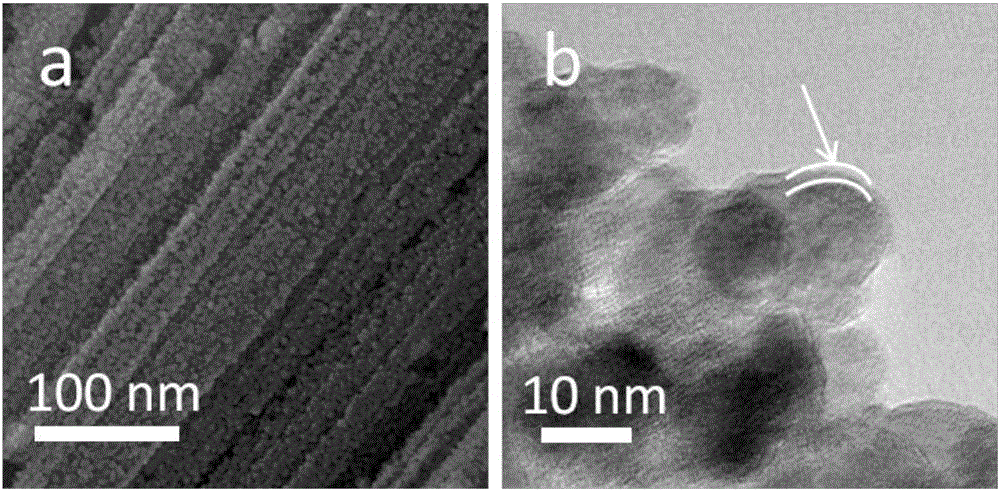

[0027] (1) Fe 3 o 4 Preparation of @C core-shell nanoparticles

[0028] 1) Add ferrous ammonium sulfate and iminodiacetic acid with a molar ratio of 2:1 into ultrapure water, configure the concentration of ferrous ammonium sulfate aqueous solution to be 0.05-0.2mol / L, and stir continuously until it is completely dissolved to obtain a mixed solution ;

[0029] 2) Transfer the above mixed solution to a reaction kettle, place the reaction kettle in a forced air drying oven at 160° C. for 12 hours, and then lower it to room temperature to obtain the precursor Fe-IDA, and wash and dry the product for later use;

[0030] 3) Put the above precursor Fe-IDA in a tube furnace, heat it to 500 °C at a heating rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com