Ellipsoidal SiOx/graphite cathode composite material and preparation method and application thereof

A composite material and graphite negative electrode technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as difficult control of sintering temperature, and achieve improved tap density, excellent cycle performance, good dispersion and fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

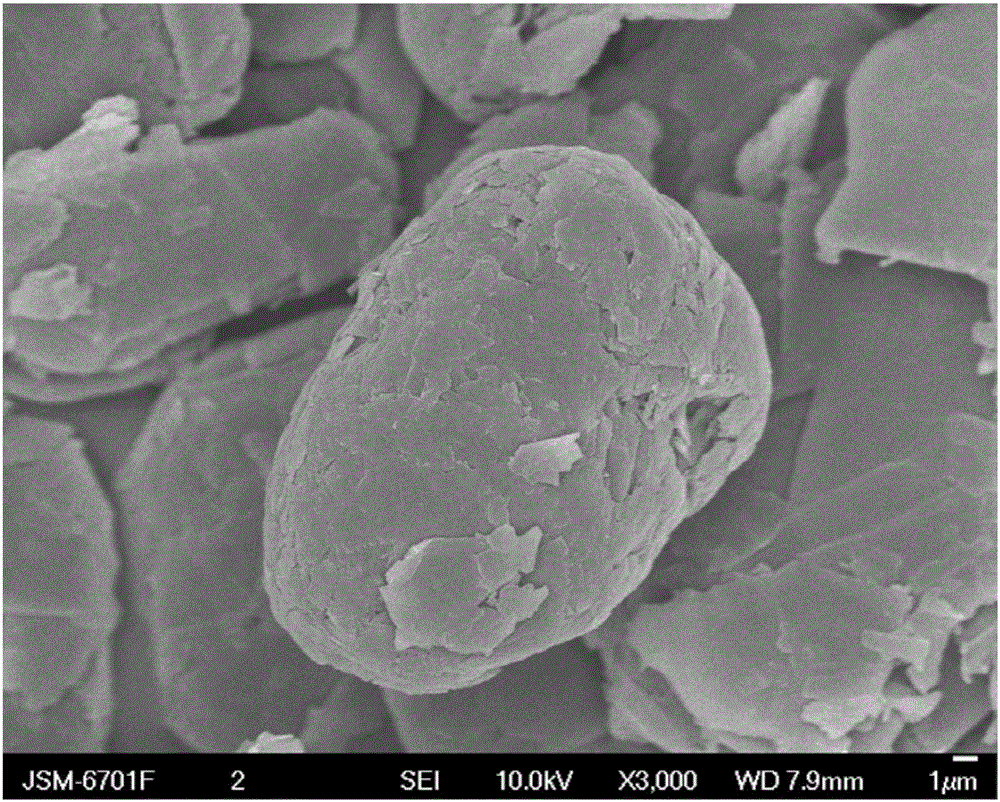

[0042] Preparation of Ellipsoidal SiOx / Graphite Anode Composite

[0043] Step 1): After ball milling silicon oxide powder with a particle size of 1mm, the particle size after crushing is about 300nm, mixed according to the mass ratio of silicon oxide: graphite = 2:8, using water as a solvent, PAN as a polymer additive, The weight-average molecular weight is 300,000, sucrose is a hydroxyl dispersant, the quality of PAN polymer additive is 3% of the total mass of silicon oxide and graphite, and the quality of sucrose is 10% of the total mass of silicon oxide and graphite. slurry;

[0044] Step 2): add an appropriate amount of water, and stir at room temperature for more than 5 hours to obtain a slurry with a viscosity of 200 mPa·s;

[0045] Step 3): Spray drying the slurry at a temperature of 150° C. to obtain powder A;

[0046] Step 4): The natural graphite is pulverized and refined by an airflow vortex micronizer, and the particle size of the natural graphite is 100 mesh;

...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is:

[0057] In step 1), the mass ratio of silicon oxide: graphite = 4:6, the particle size of silicon oxide is 5mm, and the particle size of the crushed material is 1 μm;

[0058] Step 2) the viscosity of the obtained slurry is 100mPa·s;

[0059] Step 4) The particle size of the natural graphite is 300 mesh.

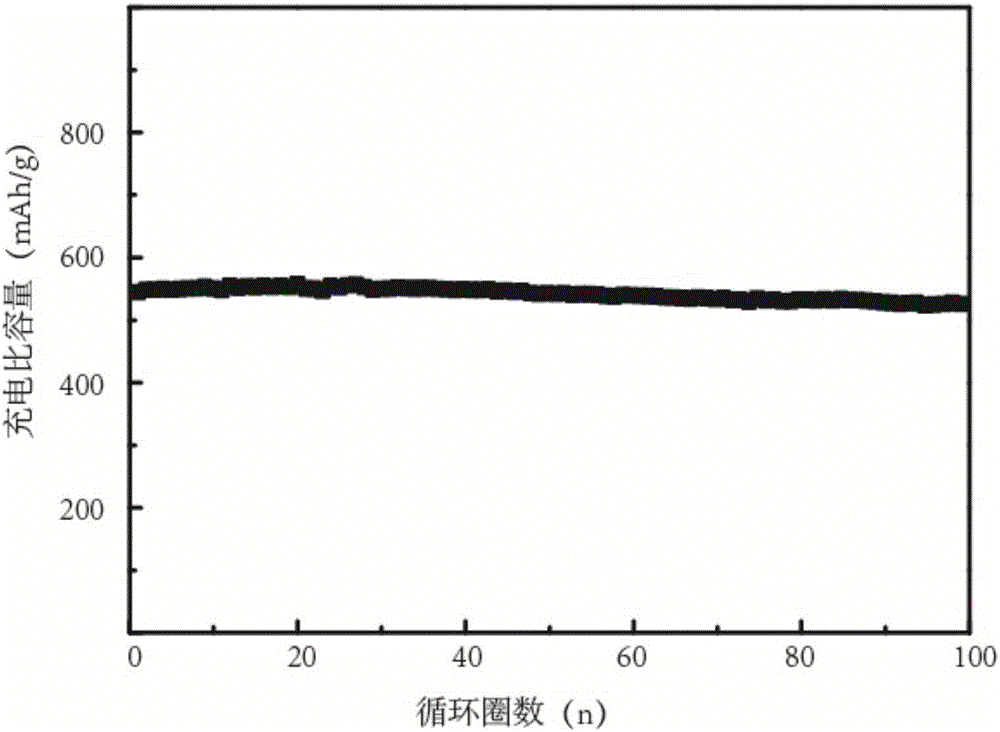

[0060] The positive electrode, negative electrode, electrolyte and battery assembly of the battery are the same as in Example 1. The composition of the obtained silicon oxide and carbon electrode materials and the test results of the battery are listed in Table 1-2.

Embodiment 3

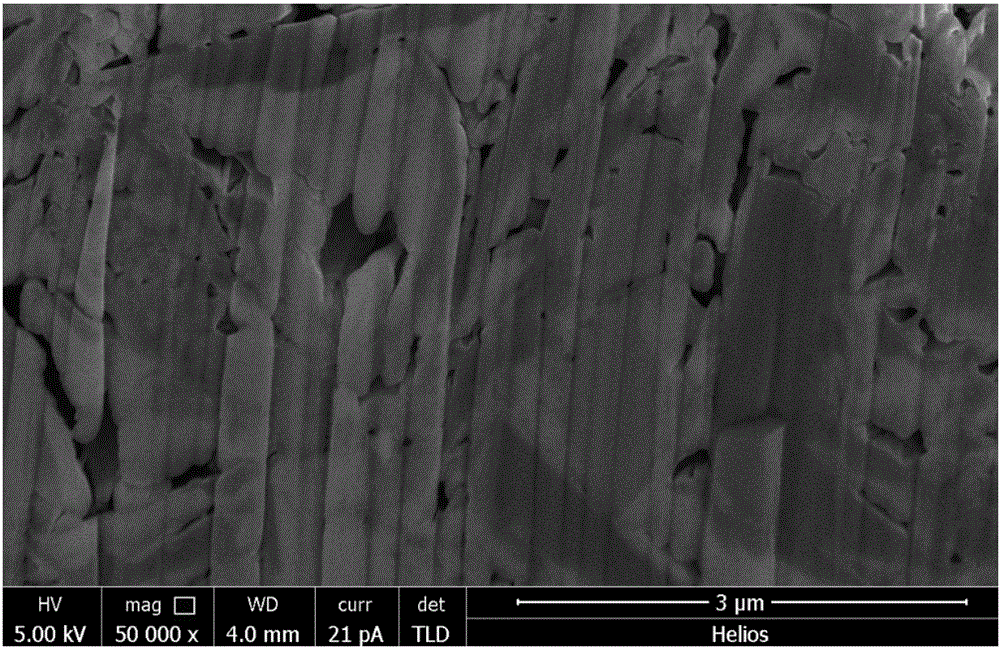

[0062] The difference between embodiment 3 and embodiment 1 is:

[0063] In step 1), carbon nanotubes are used instead of graphite, silicon oxide: carbon nanotubes = 6:4 mass ratio, the particle size of silicon oxide is 5 mm, and the particle size of the crushed material is 1 μm;

[0064] Step 2) the viscosity of the obtained slurry is 100mPa·s;

[0065] Step 3) The drying method adopts vacuum drying; the temperature is less than 180°C;

[0066] Step 4) The particle size of the natural graphite is 300 mesh.

[0067] The characterization of silicon oxide and carbon composite material is the same as that of Example 1.

[0068] The positive electrode, negative electrode, electrolyte and battery assembly of the battery are the same as in Example 1. The composition of the obtained silicon oxide and carbon electrode materials and the test results of the battery are listed in Table 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com