A kind of non-fermentation quick-thawing small steamed bun and its preparation method

A technology of small steamed buns and yeast, applied to bacteria used in food preparation, food ingredients containing yeast, food ingredients containing organic compounds, etc., can solve the problems of increased production time, avoid the growth of pathogenic bacteria, reduce time-consuming, and can highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

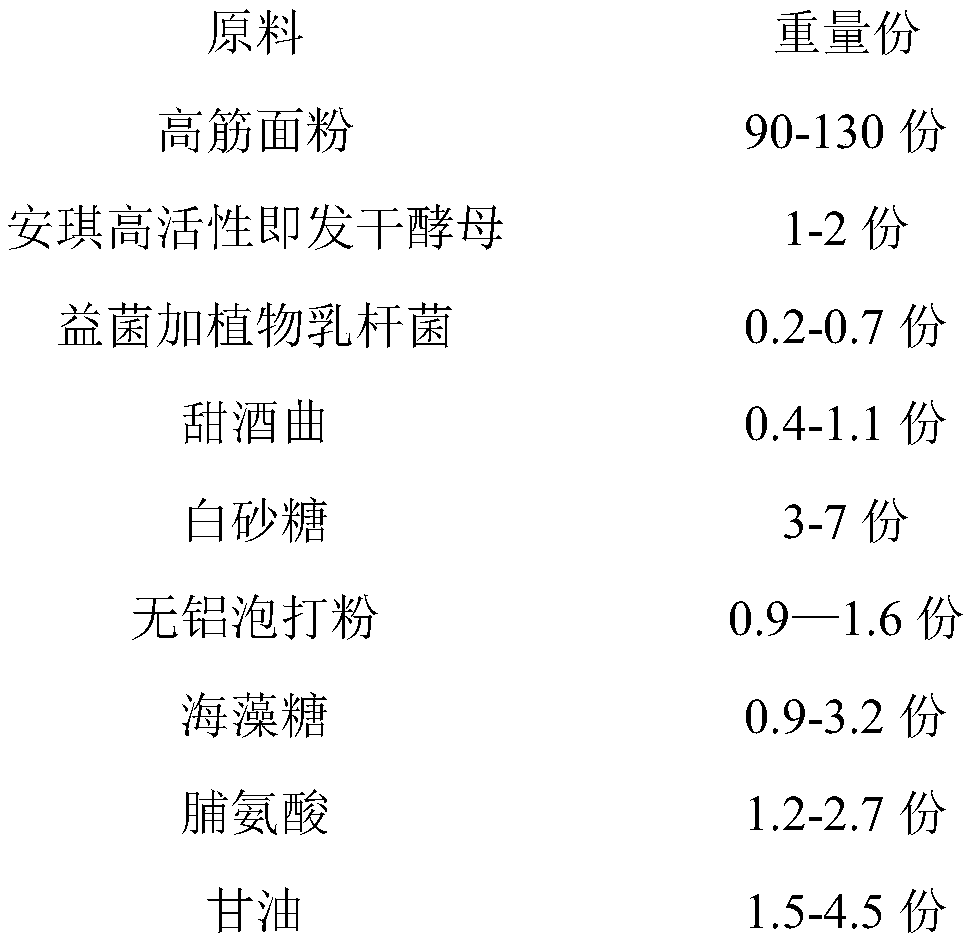

[0039] A non-fermented quick-thawed steamed bun, which is made of the following raw materials in parts by weight:

[0040]

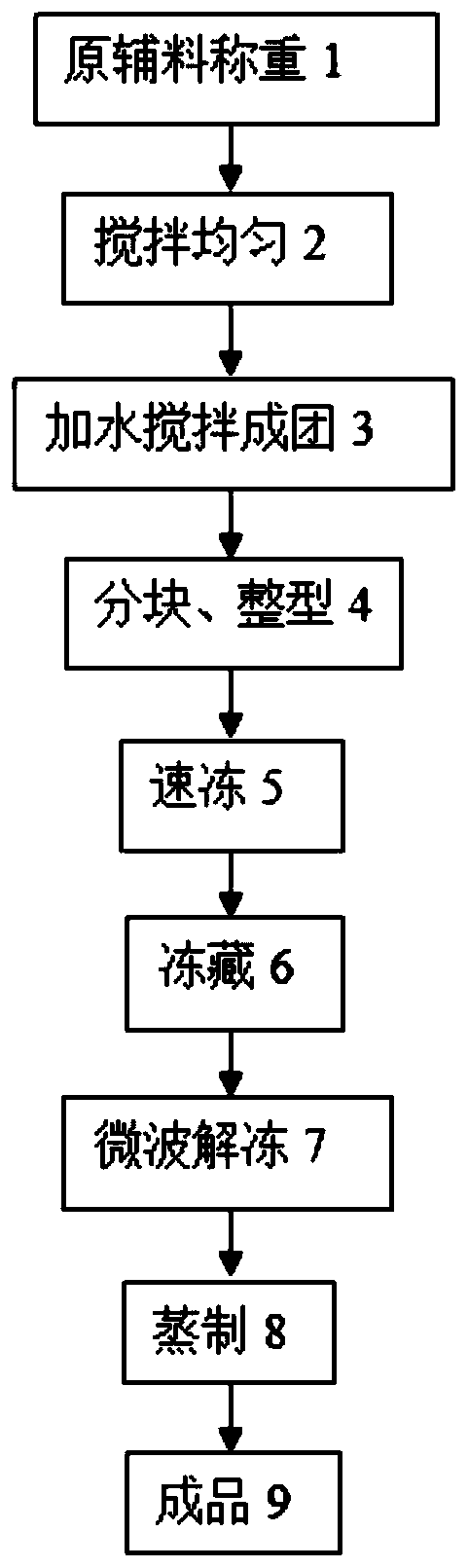

[0041] A method for preparing non-fermented quick-thawed steamed buns, the steps of which are:

[0042](1) Weigh the raw and auxiliary materials 1 and stir the raw materials evenly 2: Take a certain proportion of high-gluten flour, Angel high-activity instant dry yeast, probiotics plus Lactobacillus plantarum, sweet wine koji, white sugar, aluminum-free baking powder , trehalose, proline, glycerin, sodium stearoyl lactylate, water; add water and stir to form a mass 3: Use 15 or 17 or 18 or 20 parts of water to activate the yeast for 10 or 12 or 14 or 15 minutes, and the water temperature during activation It should reach 30 or 32 or 35°C. Add the ingredients into the mixing tank, stir slowly for 30 or 40 or 50 or 60 seconds, then add the activated yeast liquid, Lactobacillus plantarum, sweet wine koji, and water into the dough mixer, first stir slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com