Glycyrrhizin-containing enteral nutrition emulsion and preparation method thereof

A technology of enteral nutrition emulsion and glycyrrhizin, applied in the direction of vitamin-containing food ingredients, functions of food ingredients, food ingredients containing oligosaccharides, etc., can solve problems such as lowering blood sugar and rising blood sugar, and achieve improved taste and stable blood sugar levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

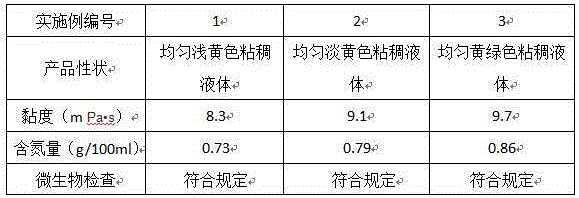

Embodiment 1

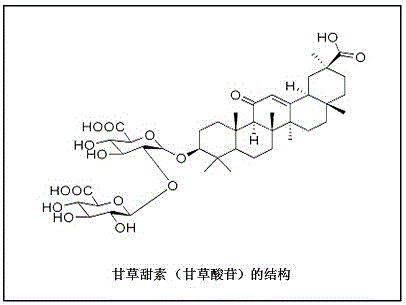

[0018] Extract Glycyrrhizin: Glycyrrhizae is crushed and 10% ethanol solvent is put into a water bath at a ratio of 1:10 for reflux extraction for 2.5 hours, then filtered, the filtrate is vacuum concentrated to obtain licorice extract, and dried to obtain brown Crude red powder. Dissolve the extract in water, adjust the pH value to 5.9 with dilute hydrochloric acid, filter to obtain glycyrrhizic acid solution, then use macroporous resin to separate, use ethanol aqueous solution to carry out gradient elution, and decolorize the obtained solution with activated carbon at 65 ° C for 30 minutes. Suction filtration, static crystallization, suction filtration, and vacuum drying to obtain the finished product of glycyrrhizic acid.

[0019] In grams by mass, take egg white protein powder 25.8g, soybean protein powder 36.2g, glycyrrhizin 3.7g, oligosaccharides 18.3, sodium chloride 0.4g, potassium chloride 1.8g, calcium carbonate 0.7g, magnesium oxide 0.4 g, iron pyrophosphate 53.4mg...

Embodiment 2

[0022] Extract Glycyrrhizin: Glycyrrhizae is crushed and 10% ethanol solvent is put into a water bath at a ratio of 1:10 for reflux extraction for 2 hours, then filtered, and the filtrate is vacuum concentrated to obtain licorice extract, which is dried to obtain brown Crude red powder. Dissolve the extract in water, adjust the pH value to 6.1 with dilute hydrochloric acid, filter to obtain glycyrrhizic acid solution, then use macroporous resin to separate, use ethanol aqueous solution to carry out gradient elution, and decolorize the obtained solution with activated carbon at 65 ° C for 30 minutes. Hot suction filtration, static crystallization, suction filtration, and vacuum drying to obtain the finished product of glycyrrhizic acid.

[0023] In grams by mass, take egg white protein powder 29.8g, soybean protein powder 33.2g, glycyrrhizin 4.2g, oligosaccharides 18.3, sodium chloride 0.4g, potassium chloride 1.8g, calcium carbonate 0.7g, magnesium oxide 0.4 g, iron pyrophosp...

Embodiment 3

[0026]Extract Glycyrrhizin: Glycyrrhizae is crushed and 10% ethanol solvent is put into a water bath at a ratio of 1:10 for reflux extraction for 3 hours, then filtered, and the filtrate is vacuum concentrated to obtain licorice extract, which is dried to obtain brown Crude red powder. Dissolve the extract in water, adjust the pH value to 6.3 with dilute hydrochloric acid, filter to obtain glycyrrhizic acid solution, then use macroporous resin to separate, use ethanol aqueous solution to carry out gradient elution, and decolorize the obtained solution with activated carbon at 65 ° C for 30 minutes. Hot suction filtration, static crystallization, suction filtration, and vacuum drying to obtain the finished product of glycyrrhizic acid.

[0027] In grams by mass, take egg white protein powder 36.5g, soybean protein powder 31.2g, glycyrrhizin 5.3g, oligosaccharides 20.7g, sodium chloride 0.4g, potassium chloride 1.8g, calcium carbonate 0.7g, magnesium oxide 0.4 g, iron pyrophosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com