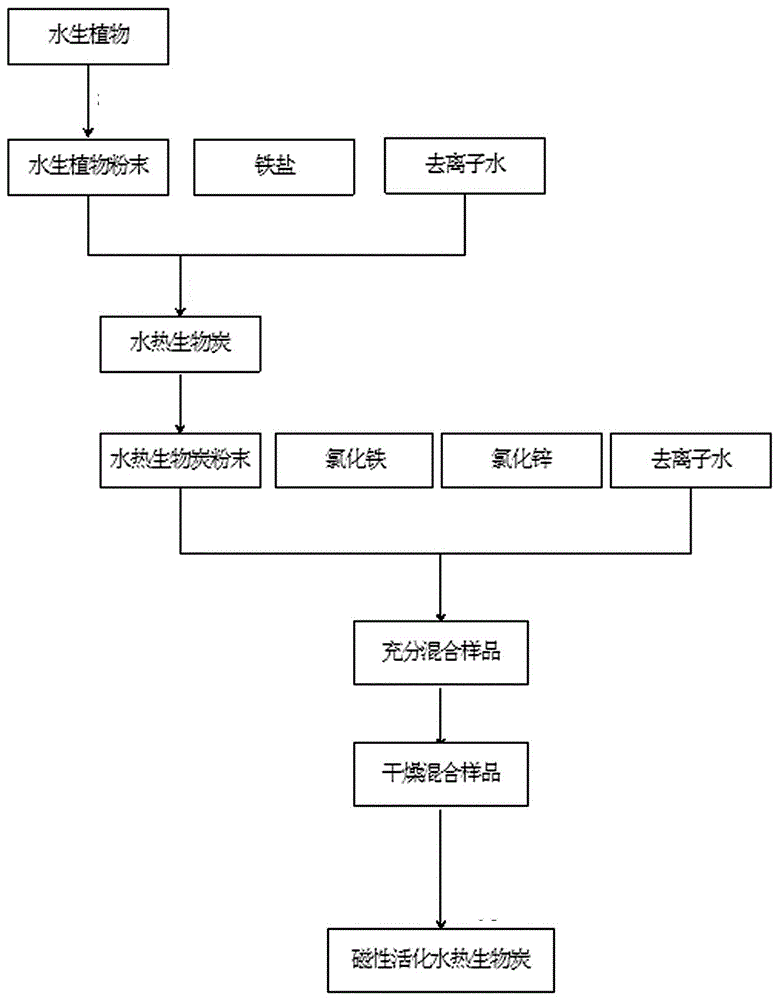

Preparation method and application of magnetic activated hydrothermal biochar microspheres

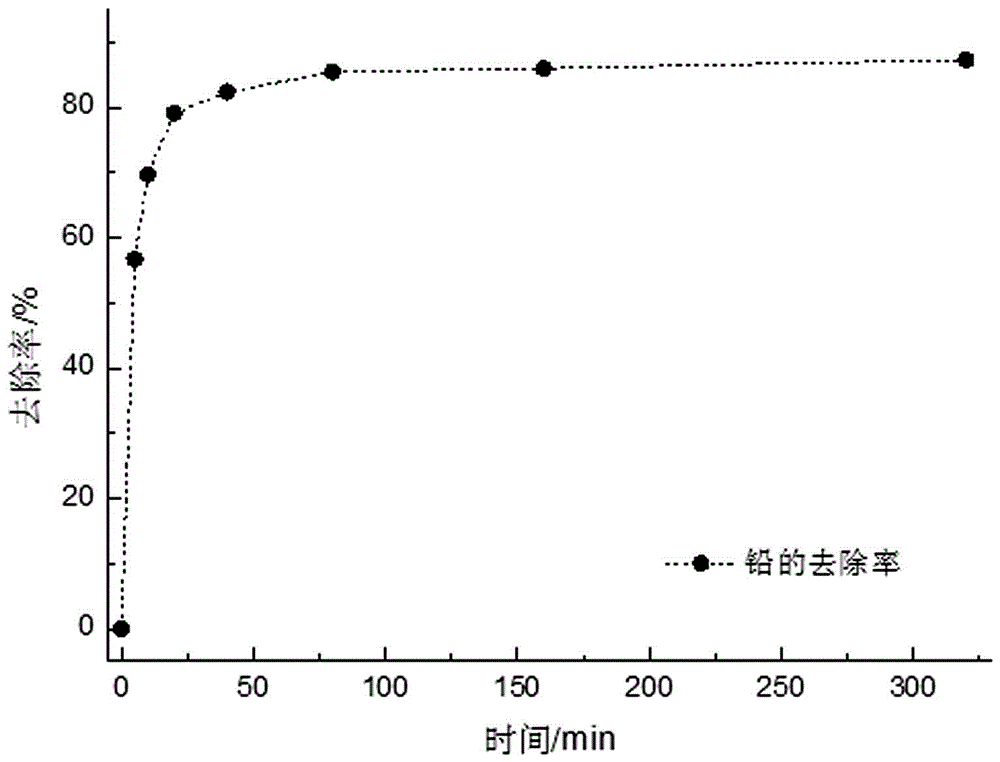

A technology of thermal biology and water activation, applied in chemical instruments and methods, biofuels, alkali metal compounds, etc., can solve the problems of low biochar yield and specific surface area, difficult separation and recovery, etc., and achieve high strength and high specific surface area , the effect of avoiding environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Al

[0043] (1) Naturally air-dry the reeds so that the internal moisture content is lower than 10%, and then crush them through a 100-mesh sieve to obtain reed powder;

[0044] (2) Weigh the mass volume ratio of reed powder, iron salt catalyst and deionized water described in step (1) to be 4:1:50; wherein the mass unit of reed powder and iron salt catalyst is gram, and the volume of deionized water is The unit is milliliters.

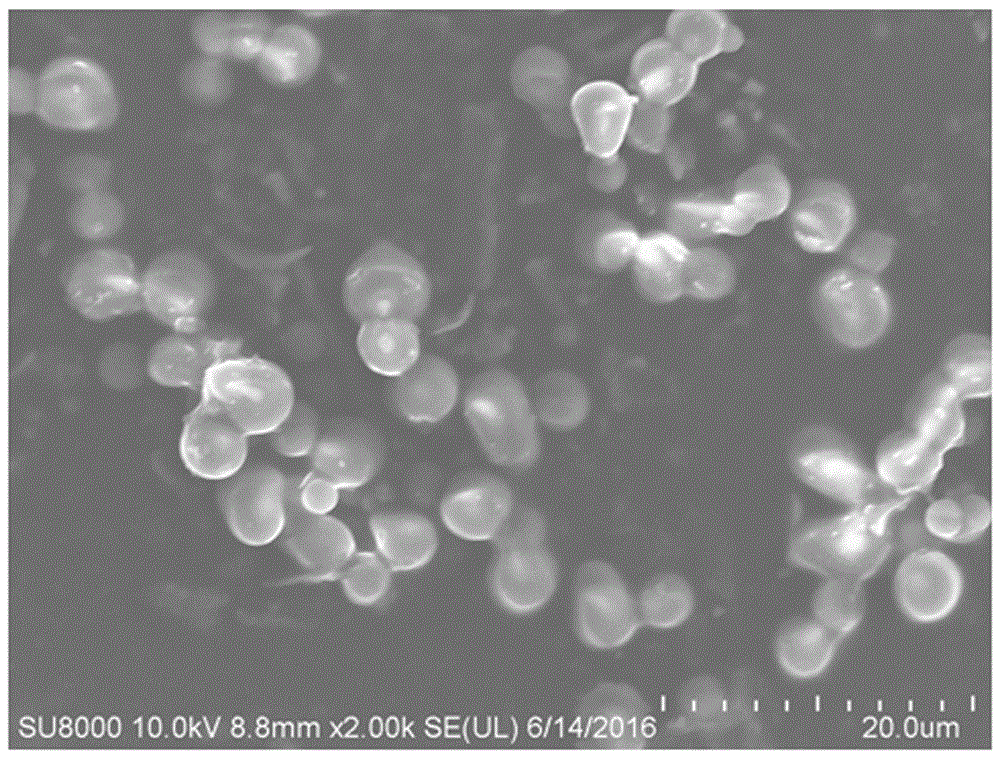

[0045] (3) The reactor described in step (2) was put into an oven, and the temperature was raised to 200°C, and kept at the final temperature for pyrolysis for 6 hours; The hydrothermal reed biochar microspheres were obtained by drying at the bottom;

[0046] (4) Weighing the hydrothermal reed biochar microspheres in step (3), grinding and pulverizing through a 100-mesh sieve to obtain hydrothermal reed biochar microsphere powder;

[0047] (5) Weigh a certain amount of hydrothermal reed biochar microsphere powder, FeCl 3 , ZnCl 2 and deionized water we...

Embodiment A2

[0051] (1) Naturally air-dry the cattail so that the internal moisture content is lower than 10%, and then crush it through a 100-mesh sieve to obtain the cattail powder;

[0052] (2) Weigh the mass volume ratio of cattail powder, iron salt catalyst and deionized water described in step (1) to be 4:1:50; wherein the mass unit of cattail powder and iron salt catalyst is gram, and the volume of deionized water is The unit is milliliters.

[0053] (3) The reactor described in step (2) was put into an oven, and the temperature was raised to 200°C, and kept at the final temperature for pyrolysis for 6 hours; The hydrothermal typha biochar microspheres were obtained by drying under the lower pressure;

[0054] (4) Weighing the hydrothermal typha biochar described in step (3), grinding and pulverizing through a 100-mesh sieve to obtain hydrothermal typha biochar microsphere powder;

[0055] (5) Weigh a certain amount of hydrothermal cattail biochar microsphere powder, FeCl 3 , ZnC...

Embodiment A3

[0059] (1) Naturally air-dry Zizania so that the internal moisture content is lower than 10%, and then crush it through a 100-mesh sieve to obtain Zizania powder;

[0060] (2) Weigh the mass-volume ratio of Zizania grass powder, iron salt catalyst and deionized water described in step (1) to be 4:1:50; wherein the mass unit of Zizania grass powder and iron salt catalyst is gram, and the mass volume ratio of deionized water is 4:1:50; The unit of volume is milliliters.

[0061] (3) The reactor described in step (2) was put into an oven, and the temperature was raised to 200°C, and kept at the final temperature for pyrolysis for 6 hours; The water-heated Zizania zizizia biochar microspheres were obtained by drying at the bottom;

[0062] (4) Weighing the hydrothermal Zizania zizizia biochar described in step (3), grinding and pulverizing it through a 100-mesh sieve to obtain the hydrothermal Zizania zizizania biochar microsphere powder;

[0063] (5) Weigh a certain amount of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com