A kind of preparation method and application of carbon quantum dot cqds hybrid cdin2s4 composite material

A technology of carbon quantum dots and composite materials, which is applied to the preparation and application of carbon quantum dots CQDs hybrid CdIn2S4 composite materials, can solve the problems of low photocatalytic quantum efficiency, low solar energy utilization rate, and limited wide application, etc. The effect of quantum efficiency, improving quantum yield, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

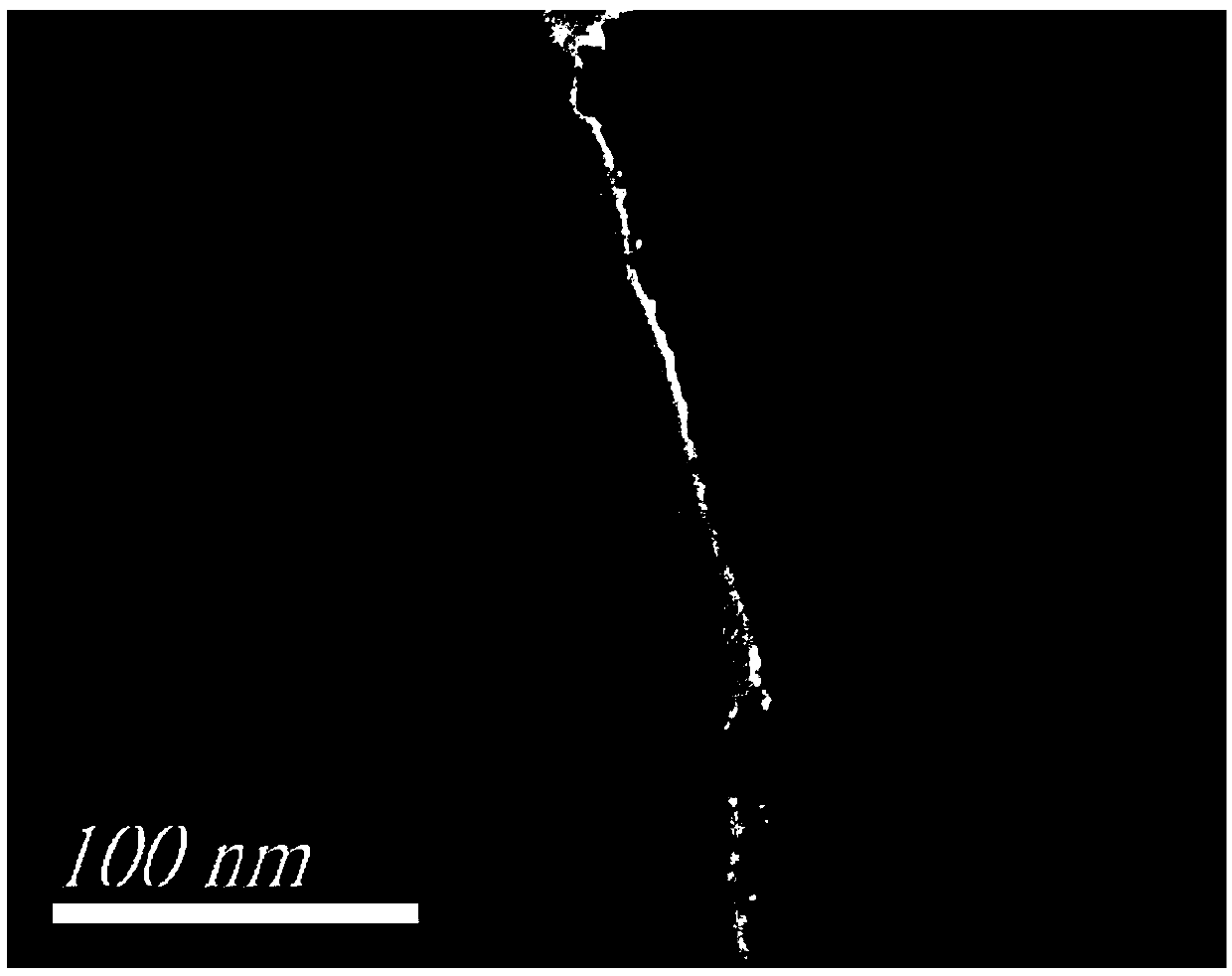

[0025] (1) Weigh 0.01g carbon quantum dots CQDs in a round bottom flask, wherein the diameter of CQDs is 2-5nm; then add 150mL deionized water and stir for 5min;

[0026] (2) Weigh 0.99g of CdIn 2 S 4 Nanoparticles in CQDs dispersion, where CdIn 2 S 4 The diameter is 50-300nm; Stir for 5min to get CdIn 2 S 4 Nanoparticle / CQDs suspension; followed by heating and reflux reaction at 70°C in an oil bath for 8h, after the reaction, the product was centrifuged, washed with deionized water and absolute ethanol twice, and then dried at 50°C under vacuum for 10h to prepare Carbon Quantum Dots CQDs Hybrid CdIn 2 S 4 Composite materials, products in which the mass fraction of CQDs is 1%.

[0027] The sample was irradiated under visible light for 3 hours, and the degradation rate of RhB reached 82.1%, and the degradation rate of levofloxacin reached 53.6%.

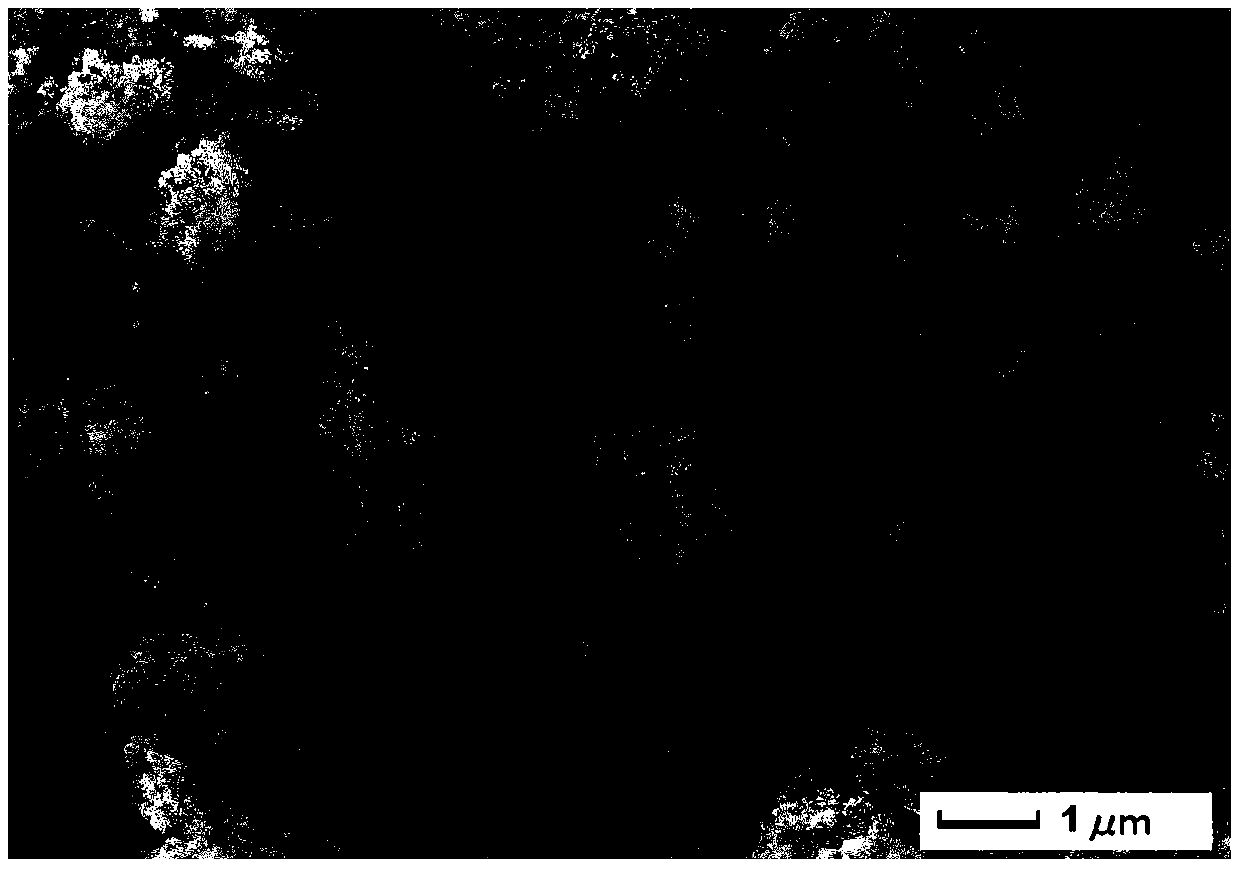

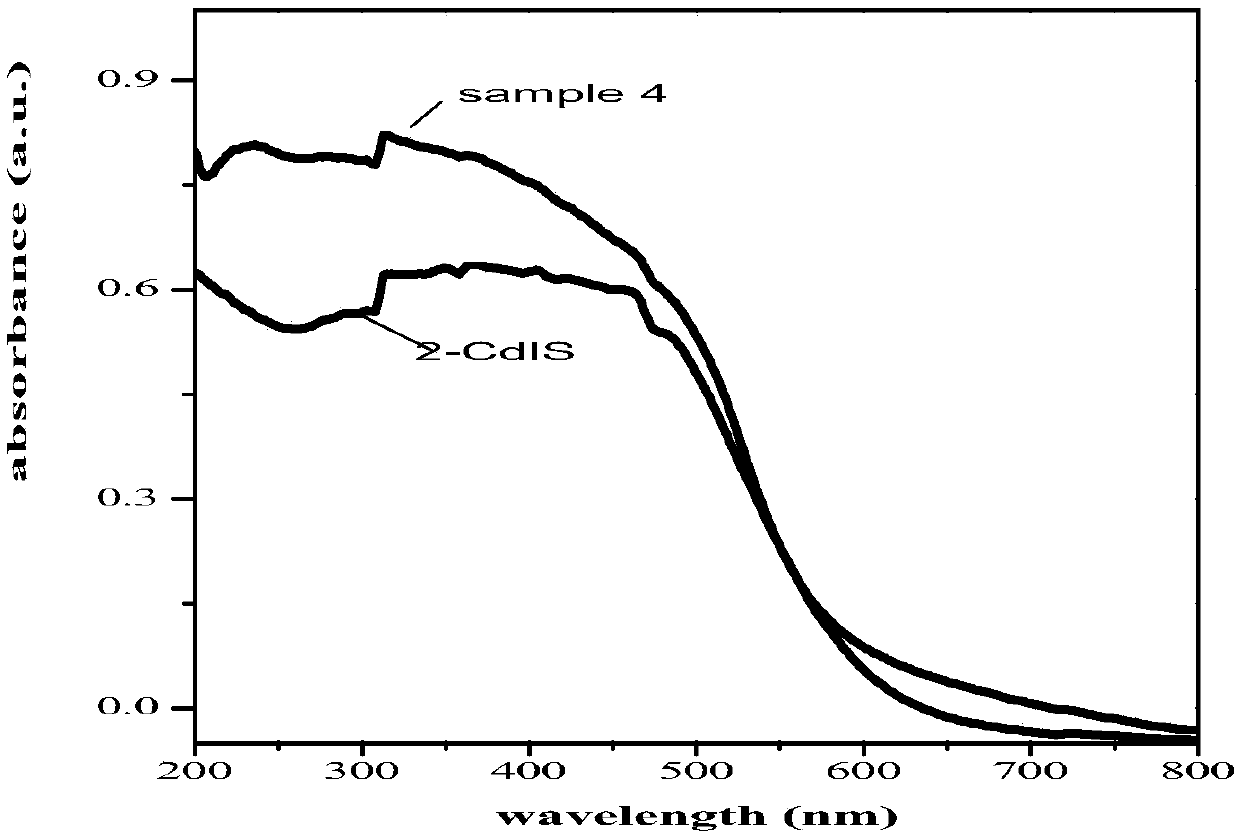

[0028] attached figure 1 For the SEM figure that is made by example 1, it can be seen from the figure that CdIn 2 S 4 The...

example 2

[0030] (1) Weigh 0.09g carbon quantum dots CQDs in a round bottom flask, wherein the diameter of CQDs is 2-5nm; then add 175mL deionized water and stir for 7min;

[0031] (2) Weigh 5.91g CdIn 2 S 4 Nanoparticles in CQDs dispersion, where CdIn 2 S 4 The diameter is 50-300nm; stir 0min to get CdIn 2 S 4Nanoparticles / CQDs suspension; then use an oil bath to heat and reflux at 80°C for 6h, centrifuge the product after the reaction, wash with deionized water and absolute ethanol twice, and dry it under vacuum at 50°C for 7h to obtain Carbon Quantum Dots CQDs Hybridized CdIn 2 S 4 Composite materials, products in which the mass fraction of CQDs is 1.5%.

[0032] The sample was irradiated under visible light for 3 hours, and the degradation rate of levofloxacin reached 61.4%, and the degradation rate of RhB reached 93.8%.

example 3

[0034] (1) Weigh 0.05g carbon quantum dots CQDs in a round bottom flask, wherein the diameter of CQDs is 2-5nm; then add 170mL deionized water and stir for 7min;

[0035] (2) Weigh 1.95g of CdIn 2 S 4 Nanoparticles in CQDs dispersion, where CdIn 2 S 4 The diameter is 50-300nm; Stir for 15min to get CdIn 2 S 4 Nanoparticles / CQDs suspension; then use an oil bath to heat and reflux at 80°C for 6h. After the reaction, the centrifuged product is washed with deionized water and absolute ethanol twice, and then dried at 60°C under vacuum for 8h , to obtain carbon quantum dots CQDs hybrid CdIn 2 S 4 Composite materials, products in which the mass fraction of CQDs is 2.5%.

[0036] The sample was irradiated under visible light for 3 hours, and the degradation rate of levofloxacin reached 72.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com