Control method for hydraulic-electric hybrid drive friction supercapacitor mine hoist

A technology for mine hoists and supercapacitors, applied in elevators, mechanical equipment, sustainable buildings, etc., can solve problems such as large volume of cascaded high-voltage inverters, large throttling loss of valve control systems, and burnout of circuit components. Achieve the effect of improving system stability, prolonging service life and reducing electric energy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

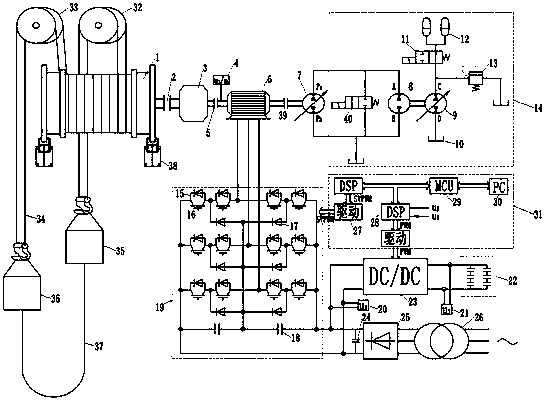

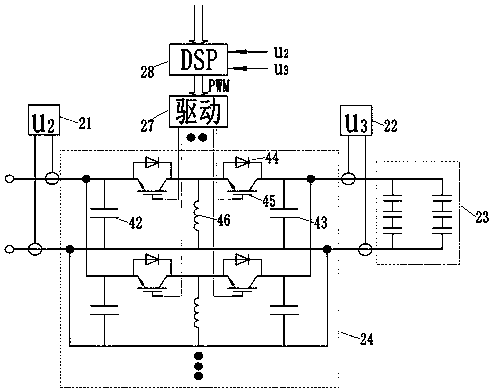

[0036] Such as figure 1 As shown, the hydroelectric hybrid drive friction type supercapacitor mine hoist of the present invention selects a friction type single drum form, including a mine hoist reel 1, a lower sky wheel 32, an upper sky wheel 33, a hoisting rope 34, and a cage. 35, cage two 36, tail rope 37, gate control system 38, first coupling 2, speed reducer 3, speed sensor 4, second coupling 5, lifting motor 6, which is characterized in that it also includes a third coupling Device 39, first hydraulic pump / motor 7, hydraulic energy storage circuit 14, three-level inverter 19, filter capacitor 24, diode rectifier bridge 25, transformer 26, DC bus side voltage detection circuit 20, bidirectional DC / DC conversion Device 23, supercapacitor side voltage detection circuit 21, supercapacitor group 22, controller 31; Lifting rope 34, cage one 35, cage two 36 are connected respectively, mine hoist reel 1 drives hoisting rope 34 by friction; Mine hoist The reel 1 is connected to...

Embodiment 2

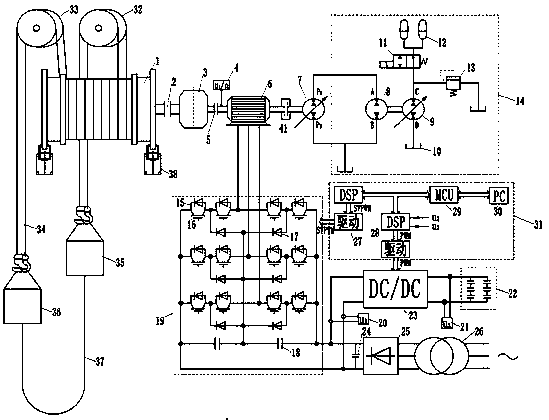

[0050] Such as figure 2 As shown, the working principle and structural composition of embodiment 2 are similar to those of embodiment 1, the difference is that in the hydraulic energy storage circuit, the electromagnetic clutch 41 is used instead of the third coupling 39, and the first two-position two-way electromagnetic Valve 40.

[0051] The working process of embodiment 2 is similar to embodiment 1, and its difference is: in embodiment 1, when controller 31 controls the first two-position two-way solenoid valve 40 to close, control electromagnetic clutch 41 to disconnect by controller 31; When the drive shaft of the first hydraulic pump / motor 7 is disconnected from the output shaft of the lifting motor 6, the first hydraulic pump / motor 7 stops working, and there is no energy flow in the hydraulic energy storage circuit 14; in embodiment 1, when the controller 31 controls When the first two-position two-way solenoid valve 40 is disconnected, the embodiment 2 controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com