A method for recovering and purifying ammonia from ammonia nitrogen wastewater

A technology for ammonia nitrogen wastewater and ammonia gas, which is applied in the preparation/separation of ammonia, chemical instruments and methods, ammonia compounds, etc., can solve the problems of low purity of recovered products and high energy consumption, and achieve a reasonable energy balance and reduce Reaction temperature, the effect of realizing resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

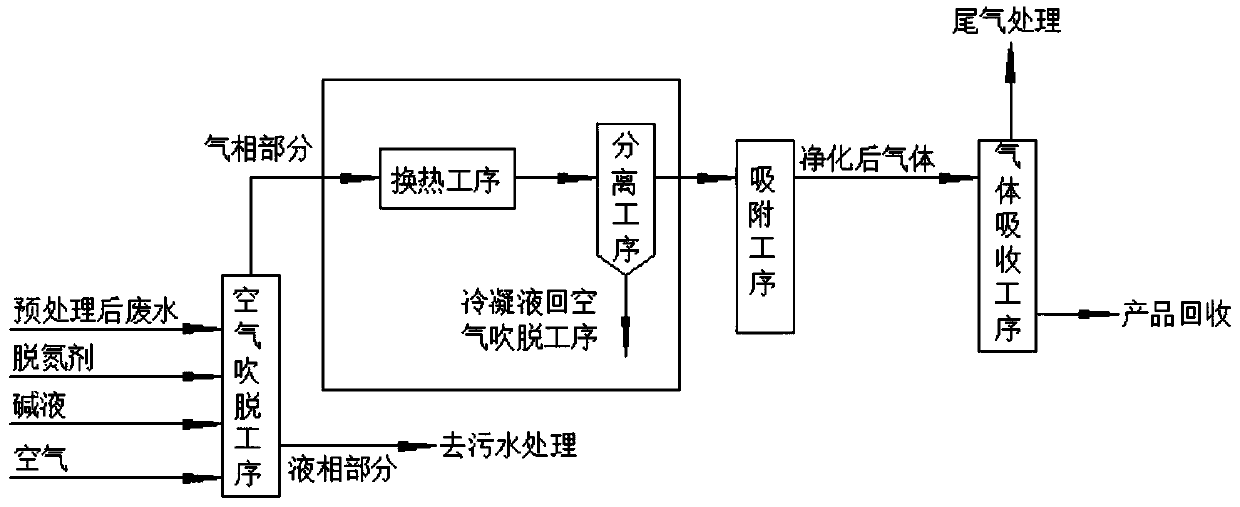

Method used

Image

Examples

Embodiment 1

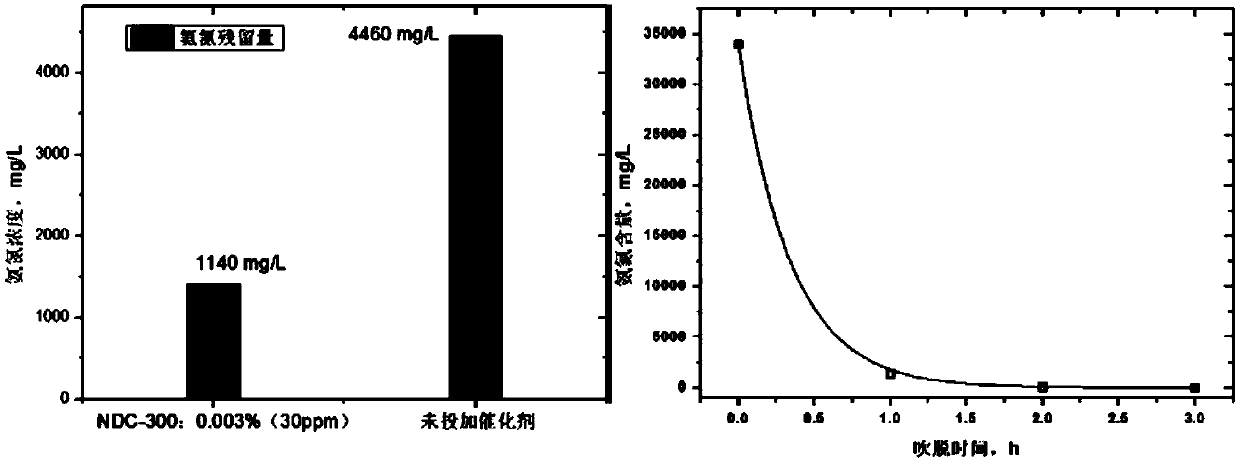

[0039] Utilize the method provided by the present invention to carry out small test experiment to the actual residual ammonia water of a certain coking plant in Shanxi, influent COD and NH 3 -N is about 5200mg / L and 1900mg / L respectively.

[0040] The remaining ammonia water is firstly removed by conventional pretreatment methods to remove oil, suspended solids, etc. in the water, and the pretreated residual ammonia water enters the air stripping system, and 5ppm of denitrification agent is added. The denitrification agent is composed of 10% ethylene glycol deaminase , 5% ferrate, 5% organic carboxylic acids, 5% hydrogen peroxide are miscible in aqueous solution. And 30% NaOH solution was used to control the pH of the wastewater during the reaction process to be 11, the reaction temperature was controlled to be 30°C, the experimental gas-water ratio was 800:1, and the stripping time was 2h. After the crude ammonia gas exported from the air stripping system is cooled by the he...

Embodiment 2

[0043] Utilize the method provided by the present invention to carry out experiment to the actual residual ammonia water of a certain coking plant in Shanxi, influent COD and NH 3 -N is about 5200mg / L and 1900mg / L respectively.

[0044] The remaining ammonia water is firstly removed by conventional pretreatment methods to remove oil, suspended solids, etc. in the water, and the pretreated residual ammonia water enters the air stripping system without adding denitrification agent, and uses 30% NaOH solution to control the pH of the wastewater during the reaction process. 14. Control the reaction temperature to 90°C, and the experimental gas-water ratio to 5500:1. After the crude ammonia gas exported from the air stripping system is cooled by the heat exchanger, the cooled liquid undergoes gas-liquid separation and returns to the stripping tower for secondary stripping. The cooled ammonia gas enters the adsorption device for the adsorption of organic waste , the adsorbent used ...

Embodiment 3

[0047] Utilize the method provided by the present invention to carry out experiment to the actual residual ammonia water of a certain coking plant in Shanxi, influent COD and NH 3 -N is about 5200mg / L and 1900mg / L respectively.

[0048] The remaining ammonia water is firstly removed by conventional pretreatment methods to remove oil, suspended solids, etc. in the water, and the pretreated residual ammonia water enters the air stripping system, and 15ppm of denitrification agent is added. The denitrification agent is composed of 15% ethylene glycol deaminase , ferrate 7%, organic carboxylic acids 15%, hydrogen peroxide 15% miscible in aqueous solution, and use 30% NaOH solution to control the pH of the wastewater in the reaction process to be 9, control the reaction temperature to 70 °C, and the experimental gas The water ratio is 3000:1. After the crude ammonia gas exported from the air stripping system is cooled by the heat exchanger, the cooled liquid undergoes gas-liquid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com