Biological organic nutrient solution and preparation method thereof

A nutrient solution and organic technology, which is applied in the functional bio-organic nutrient solution for promoting the growth of crops and commercial crops and its preparation, in the field of bio-organic nutrient solution, can solve the problems of insufficient comprehensive and balanced fertilizer efficiency, single nutrient components, etc., so as to improve crops quality, improving stress resistance, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

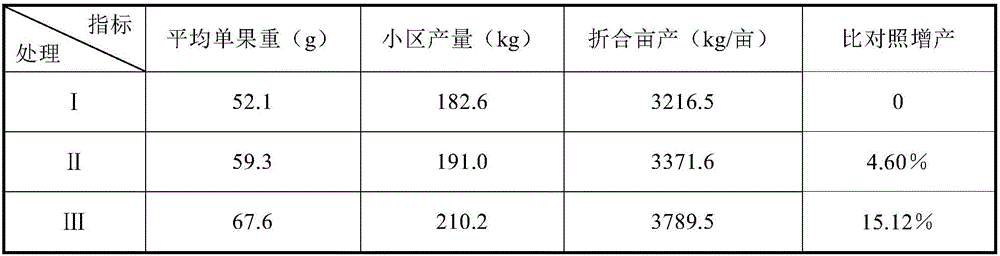

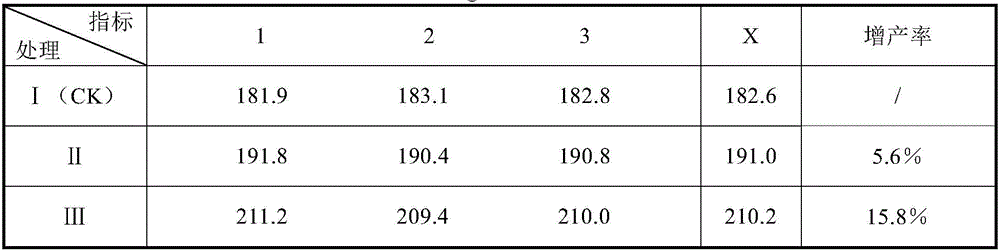

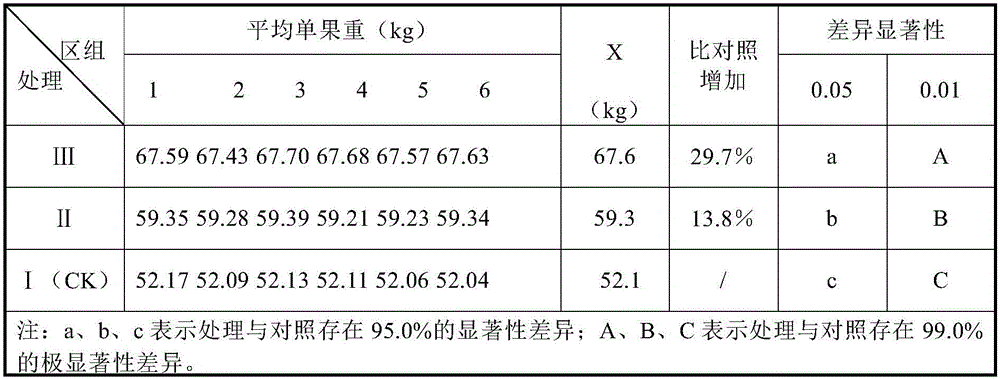

Examples

Embodiment 1

[0048] (1) Add raw material water, potassium nitrate, ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate, calcium nitrate, amino acid powder, and fulvic acid powder into a vertical interlayer mixer with heating function in a certain proportion and mix for 10 minutes. The temperature is 30°C;

[0049] The ratio of each component is: water 300kg, potassium nitrate 100kg, ammonium sulfate 80kg, potassium dihydrogen phosphate 140kg, magnesium sulfate 25kg, calcium nitrate 20kg, amino acid 160kg, fulvic acid 120kg.

[0050] (2) Put 2kg of zinc sulfate, 2kg of manganese sulfate, 3kg of boric acid, 1kg of sodium selenite, 3kg of polyaspartic acid, 5kg of amino oligosaccharin, 1kg of Bacillus subtilis, 1kg of PGPR probiotics, and 2kg of EM probiotics into V Mix in a type mixer for 7 minutes;

[0051] (3) After the material obtained in step (2) is fully mixed evenly by stirring, it is added to the liquid mixture in step (1), and fully mixed for 20 minutes at a tempera...

Embodiment 2

[0057] (1) Add raw material water, potassium nitrate, ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate, calcium nitrate, amino acid powder, and fulvic acid powder into a vertical interlayer mixer with heating function in a certain proportion and mix for 13 minutes. The temperature is 27°C;

[0058] The ratio of each component is: water 330kg, potassium nitrate 130kg, ammonium sulfate 90kg, potassium dihydrogen phosphate 160kg, magnesium sulfate 27kg, calcium nitrate 25kg, amino acid 170kg, fulvic acid 130kg.

[0059] (2) 2.5kg of zinc sulfate, 2.5kg of manganese sulfate, 3.5kg of boric acid, 1.5kg of sodium selenite, 5kg of polyaspartic acid, 7kg of amino oligosaccharides, 1.5kg of Bacillus subtilis, 1.5kg of PGPR probiotics, Put 2.5kg of EM probiotics into the V-type mixer and mix for 9 minutes;

[0060] (3) After the material obtained in step (2) is thoroughly mixed evenly by stirring, it is added to the liquid mixture in step (1), and fully mixed for 22 ...

Embodiment 3

[0066] (1) Add raw material water, potassium nitrate, ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate, calcium nitrate, amino acid powder, and fulvic acid powder into a vertical interlayer mixer with heating function in a certain proportion and mix for 15 minutes. The temperature is 25°C;

[0067] The ratio of each component is: water 350kg, potassium nitrate 140kg, ammonium sulfate 100kg, potassium dihydrogen phosphate 180kg, magnesium sulfate 30kg, calcium nitrate 30kg, amino acid 180kg, fulvic acid 140kg.

[0068] (2) Put 3kg of zinc sulfate, 3kg of manganese sulfate, 4kg of boric acid, 2kg of sodium selenite, 6kg of polyaspartic acid, 8kg of amino oligosaccharin, 2kg of Bacillus subtilis, 2kg of PGPR probiotics, and 3kg of EM probiotics into V Mix in a type mixer for 10 minutes;

[0069] (3) After the material obtained in step (2) is thoroughly mixed evenly by stirring, it is added to the liquid mixture in step (1), and fully mixed for 25 minutes at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com