Molybdenum-tungsten alloy and preparation method thereof

A molybdenum-tungsten alloy and raw material technology, applied in the field of molybdenum-tungsten alloy and its preparation, can solve the problems of insufficient strength of molybdenum-tungsten alloy and achieve excellent strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

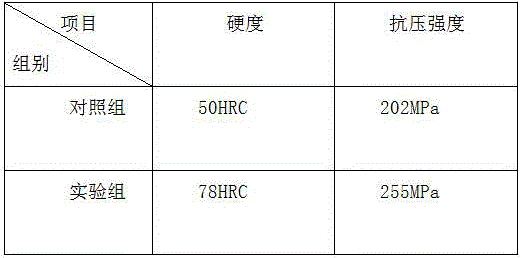

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A molybdenum-tungsten alloy, comprising the following raw materials in parts by weight: 102 parts of molybdenum, 80 parts of tungsten, 2 parts of magnesium, 1 part of zinc, 4 parts of hafnium nitride, 2 parts of yttrium oxide, 1 part of thulium, 1 part of terbium, 1 part of erbium, 4 parts of polycrystalline mullite fiber, 2 parts of titanium oxide, 2 parts of tricobalt tetroxide and 5 parts of dichromium trioxide.

[0016] A preparation method of molybdenum-tungsten alloy comprises the following steps:

[0017] 1) Pour 102 parts of molybdenum, 80 parts of tungsten, 2 parts of magnesium, 1 part of zinc, 4 parts of hafnium nitride, 2 parts of yttrium oxide, 1 part of thulium, 1 part of terbium and 1 part of erbium into the metal melting furnace, and then Heating to 600°C, stirring after all the raw materials are completely melted, to obtain liquid metal, set aside;

[0018] 2) Pour 4 parts of polycrystalline mullite fiber, 2 parts of titanium oxide, 2 parts of tricobalt...

Embodiment 2

[0021] A molybdenum-tungsten alloy, comprising the following raw materials in parts by weight: 100 parts of molybdenum, 82 parts of tungsten, 4 parts of magnesium, 3 parts of zinc, 6 parts of hafnium nitride, 4 parts of yttrium oxide, 3 parts of thulium, 3 parts of terbium, 3 parts of erbium, 6 parts of polycrystalline mullite fiber, 4 parts of titanium oxide, 4 parts of tricobalt tetroxide and 7 parts of dichromium trioxide.

[0022] A preparation method of molybdenum-tungsten alloy, comprising the following steps:

[0023] 1) Pour 100 parts of molybdenum, 82 parts of tungsten, 4 parts of magnesium, 3 parts of zinc, 6 parts of hafnium nitride, 4 parts of yttrium oxide, 3 parts of thulium, 3 parts of terbium and 3 parts of erbium into the metal melting furnace, and then Heating to 600°C, stirring after all the raw materials are completely melted, to obtain liquid metal, set aside;

[0024] 2) Pour 6 parts of polycrystalline mullite fiber, 4 parts of titanium oxide, 4 parts of...

Embodiment 3

[0027] A molybdenum-tungsten alloy, comprising the following raw materials in parts by weight: molybdenum 101, tungsten 81, magnesium 3 parts, zinc 2 parts, hafnium nitride 5 parts, yttrium oxide 3 parts, thulium 2 parts, terbium 2 parts, erbium 2 parts, polycrystalline mullite fiber 5 parts, titanium oxide 3 parts, tricobalt tetroxide 3 parts and dichromium trioxide 6 parts.

[0028] A preparation method of molybdenum-tungsten alloy, comprising the following steps:

[0029] 1) Pour 101 parts of molybdenum, 81 parts of tungsten, 3 parts of magnesium, 2 parts of zinc, 5 parts of hafnium nitride, 3 parts of yttrium oxide, 2 parts of thulium, 2 parts of terbium and 2 parts of erbium into the metal melting furnace, and then Heating to 600°C, stirring after all the raw materials are completely melted, to obtain liquid metal, set aside;

[0030] 2) Pour 5 parts of polycrystalline mullite fiber, 3 parts of titanium oxide, 3 parts of cobalt tetroxide and 6 parts of chromium trioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com