Substituted chromic acid passivation environmental protection process

An environmental protection and process technology, applied in the field of environmental protection technology to replace chromic acid passivation, can solve the problems of long processing time, poor corrosion resistance, high processing temperature, and achieve good film formation effect, dense and uniform film formation, and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

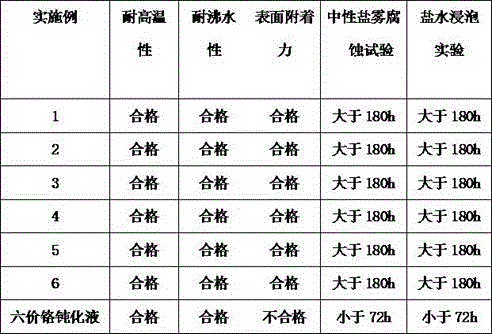

Examples

Embodiment 1

[0021] An environmentally friendly process that replaces chromic acid passivation. The passivation solution used for passivation consists of the following components: ammonium persulfate 10g / L, phytic acid 2g / L, trisodium phosphate 15g / L, phosphoric acid 1mL / L, Boric acid 0.5mL / L, zirconium tetrapropoxide 0.5g / L, benzotriazole 0.1g / L, complexing agent 3g / L, water-soluble polyester film-forming resin 5g / L, nano silicon oxide 4g / L, 0.1 g / L of ethylenediaminetetraacetic acid, and the rest is water; the complexing agent is composed of triethanolamine and tetrasodium hydroxyethylidene diphosphonate in a weight ratio of 1:2.

Embodiment 2

[0023] An environmentally friendly process that replaces chromic acid passivation. The passivation solution used for passivation consists of the following components: ammonium persulfate 20g / L, phytic acid 6g / L, trisodium phosphate 25g / L, phosphoric acid 3mL / L, Boric acid 1mL / L, zirconium tetrapropoxide 3g / L, benzotriazole 1g / L, complexing agent 6g / L, water-soluble styrene-acrylic film-forming resin 10g / L, nano-silica 6g / L, stabilizer C The diacid is 3 g / L, and the rest is water; the complexing agent is composed of triethanolamine and tetrasodium hydroxyethylidene diphosphonate in a weight ratio of 1:1.2.

Embodiment 3

[0025] An environmentally friendly process that replaces chromic acid passivation. The passivation solution used for passivation consists of the following components: ammonium persulfate 15g / L, phytic acid 4g / L, trisodium phosphate 20g / L, phosphoric acid 2mL / L, Boric acid 0.8mL / L, zirconium tetrapropoxide 1.5g / L, benzotriazole 0.4g / L, complexing agent 4g / L, water-soluble epoxy film-forming resin 8g / L, nano silicon oxide 5g / L, The stabilizer sodium citrate is 1.3g / L, and the rest is water; the complexing agent is composed of triethanolamine and tetrasodium hydroxyethylidene diphosphonate in a weight ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com