Preparation method of regenerated silk protein fiber based on rare-earth/metal ions

A technology of regenerated silk and protein fibers, which is applied in the field of preparation of regenerated silk protein fibers, can solve the problems of few researches on regenerated silk fibers, achieve skin-friendly and good biocompatibility, improve mechanical strength and toughness, mechanical properties and Functional good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

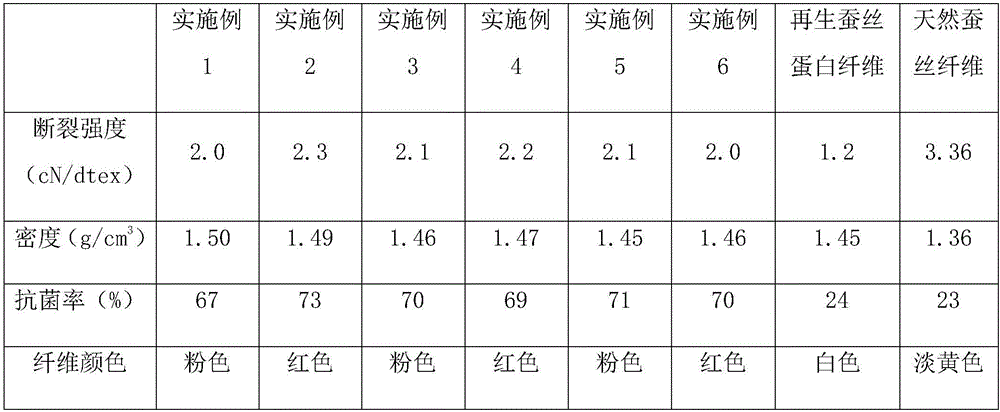

Examples

Embodiment 1

[0029] (1) After degumming the silk, place it in CaCl with a molar ratio of 1:2:8 2 、C 2 h 5 OH and H 2 O ternary solution, heated and stirred at 60° C. and 500 rpm for 2 h to dissolve, dialyzed, and concentrated to obtain a 5% mass fraction of silk protein aqueous solution with a relative molecular weight of 126-238 kDa.

[0030] (2) In parts by weight, dissolve 15 parts of chloroauric acid in deionized water, add 20 parts of a rare earth mixture of cerium chloride and lanthanum chloride with a molar ratio of 1:1, and after fully stirring, add 50 parts of The aqueous solution of silk protein is adjusted to a pH value of 7.5 to obtain a modified silk protein solution.

[0031] (3) Mix the silk protein modification solution with a volume ratio of 50:2 and the glutaraldehyde crosslinking agent, stir at a constant temperature for 30 minutes at 4° C., and let stand for 5 minutes to obtain a spinning solution.

[0032] (4) Pour the spinning solution into the syringe, at room te...

Embodiment 2

[0034] (1) After degumming the silk, place it in CaCl with a molar ratio of 1:2:8 2 、C 2 h 5 OH and H 2 O ternary solution, heated and stirred at 70° C. and 700 rpm for 3 h to dissolve, dialyzed, and concentrated to obtain an aqueous silk protein solution with a mass fraction of 8% and a relative molecular weight of 126-238 kDa.

[0035] (2) In parts by weight, dissolve 20 parts of chloroauric acid in deionized water, add 25 parts of a rare earth mixture of cerium chloride and lanthanum chloride with a molar ratio of 1:1, and after fully stirring, add 70 parts of The aqueous solution of silk protein is adjusted to a pH value of 8.5 to obtain a modified silk protein solution.

[0036] (3) Mix the silk protein modification solution with a volume ratio of 50:5 and the glutaraldehyde crosslinking agent, stir at a constant temperature of 10° C. for 60 minutes, and let stand for 10 minutes to obtain a spinning solution.

[0037] (4) Spinning solution is poured in the syringe, at...

Embodiment 3

[0039] (1) After degumming the silk, place it in CaCl with a molar ratio of 1:2:8 2 、C 2 h 5 OH and H 2 O ternary solution, heated and stirred at 65° C. and 600 rpm for 2.5 h to dissolve, dialyzed, and concentrated to obtain an aqueous silk protein solution with a mass fraction of 6% and a relative molecular weight of 126-238 kDa.

[0040](2) In parts by weight, dissolve 18 parts of chloroauric acid in deionized water, add 22 parts of a rare earth mixture of cerium chloride and lanthanum chloride with a molar ratio of 1:1, and after fully stirring, add 60 parts of The aqueous solution of silk protein is adjusted to a pH value of 8 to obtain a modified silk protein solution.

[0041] (3) Mix the silk protein modification solution with a volume ratio of 50:3 and the glutaraldehyde crosslinking agent, stir at a constant temperature at 6° C. for 40 minutes, and let stand for 8 minutes to obtain a spinning solution.

[0042] (4) Spinning solution is poured in the syringe, at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com