Direct current supply metal halide lamp

A technology of metal halide lamps and metal halides, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve problems such as jittering light effect, arc flicker of DC metal halide lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

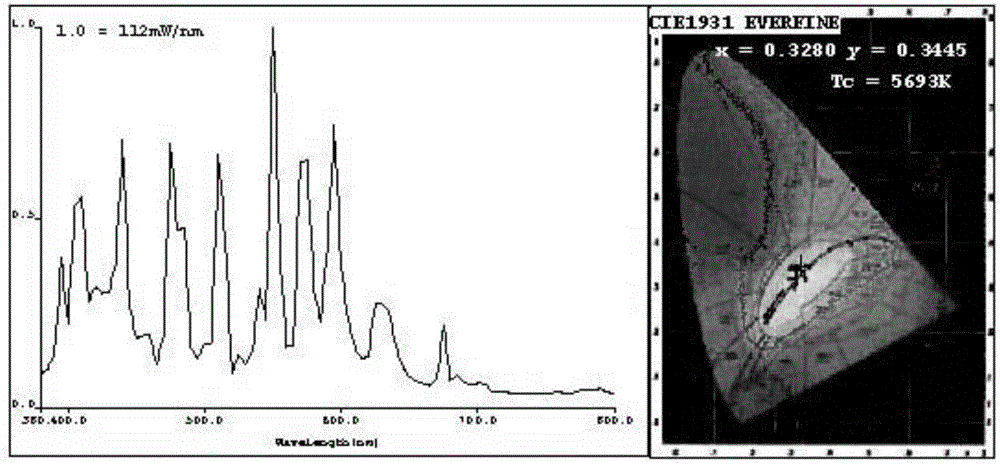

[0025] In a DC 35W quartz xenon metal halide lamp, the volume of the arc tube is 0.035mL; the electrode anode diameter is 0.32mm tungsten rod, the cathode diameter is 0.25mm tungsten rod; the distance between electrodes is 4.0mm; -5 Pa; the concentration of 0.72 mg of mercury metal is 20.1 mg / mL; the total concentration of metal halides is 9.4 mg / mL; the typical component sodium is 55wt% (wt% means the mass percentage content is the same below); the typical scandium is 25.5wt%; Typical thallium 1.5wt%; typical zinc 18wt%. A total of five light bulbs have a switch cycle of: 45min on, 15s off, 5min on, 10min off. After 15 aging cycles, use a constant power DC output 34W ballast to ignite horizontally and test five sets of data in an integrating sphere to take the average value. The parameters are as follows:

[0026] Luminous flux Φ=2534.9lm; color coordinate x=0.3280y=0.3445; correlated color temperature Tc=5693K; color rendering index: Ra=73.7, tube voltage: U=85.1V; tube cur...

Embodiment 2

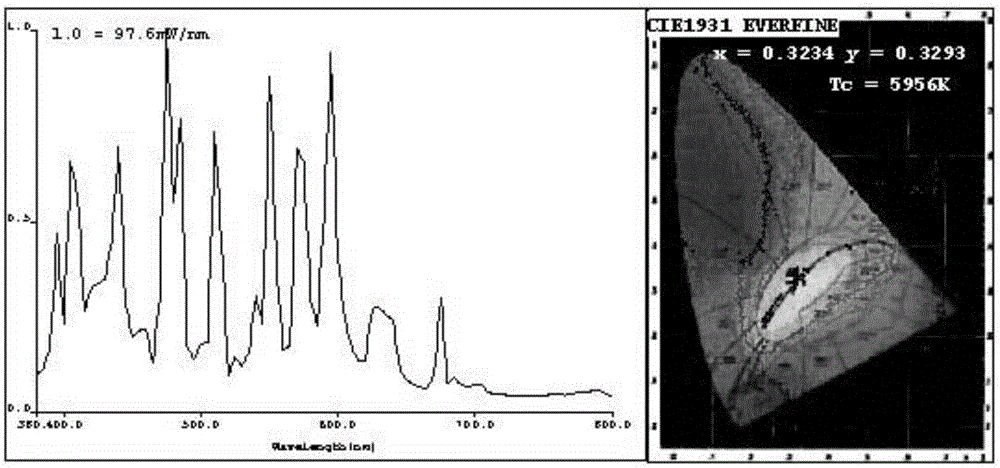

[0031] In a DC 35W quartz xenon metal halide lamp, the volume of the arc tube is 0.035mL; the electrode anode diameter is 0.32mm tungsten rod, the cathode diameter is 0.25mm tungsten rod; the distance between electrodes is 4.0mm; -5 Pa; the concentration of 0.78 mg of mercury metal is 22.3 mg / mL; the total concentration of metal halides is 9.4 mg / mL; the typical component sodium is 64wt% (wt% means the mass percentage content is the same below); the typical scandium is 34.5wt%; Typical thallium 1.5wt%; typical zinc 0wt%. A total of five bulbs are switched on and off in the following cycle: 45min on, 15s off, 5min on, 10min off. After 15 aging cycles, the aging method, testing method and test ballast are the same as in Example 1:

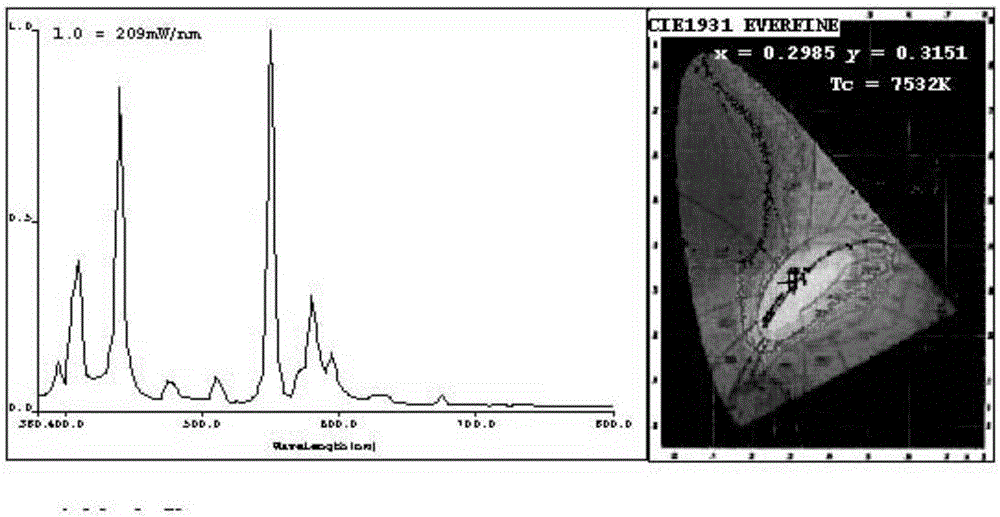

[0032] Luminous flux Φ=1746.2lm; color coordinate x=0.2985y=0.3151; correlated color temperature Tc=7532K; color rendering index: Ra=43.9, tube voltage: U=86.5V; tube current: I=0.393A; power: P=34.0 W; light effect: η=51.4lm / W. image 3 It is a ty...

Embodiment 3

[0035] In a DC 35W quartz xenon metal halide lamp, the volume of the arc tube is 0.035mL; the electrode anode diameter is 0.32mm tungsten rod, the cathode diameter is 0.25mm tungsten rod; the distance between electrodes is 4.0mm; -5 Pa; the concentration of 0.65 mg of mercury metal is 18.6 mg / mL; the total concentration of metal halides is 9.4 mg / mL; the typical component sodium is 46.8wt% (wt% means the same as the mass percentage content below); the typical scandium is 21.7wt% ; Typical thallium 1.5wt%; Typical zinc 30wt%. The aging method and test method and the test ballast are the same as in Example 1:

[0036] Luminous flux Φ=1992.6lm; color coordinate x=0.3152y=0.3236; correlated color temperature Tc=6404K; color rendering index: Ra=78.2, tube voltage: U=84.2V; tube current: I=0.40A; power: P=34.0 W; light effect η=58.57lm / W. Figure 4 It is a typical spectral distribution figure during the initial ignition point of Example 3.

[0037] Results: The lamp arc with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com