A kind of graphite composite negative electrode material and preparation method thereof

A technology for negative electrode materials and composite material layers, which is applied in the field of graphite composite negative electrode materials and its preparation, can solve problems such as material cycle performance to be improved, and achieve the effects of improving first-time efficiency, increasing doping rate, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

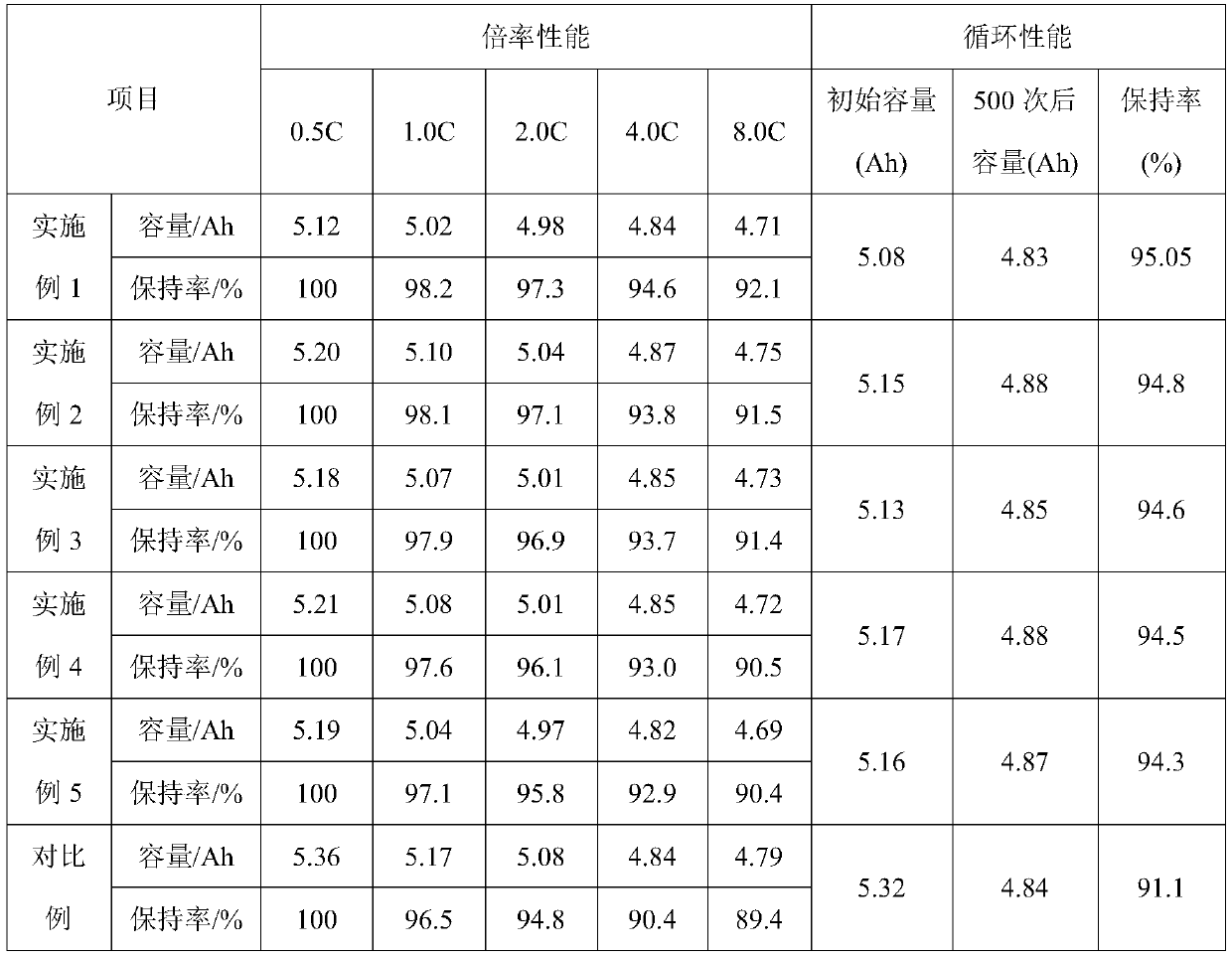

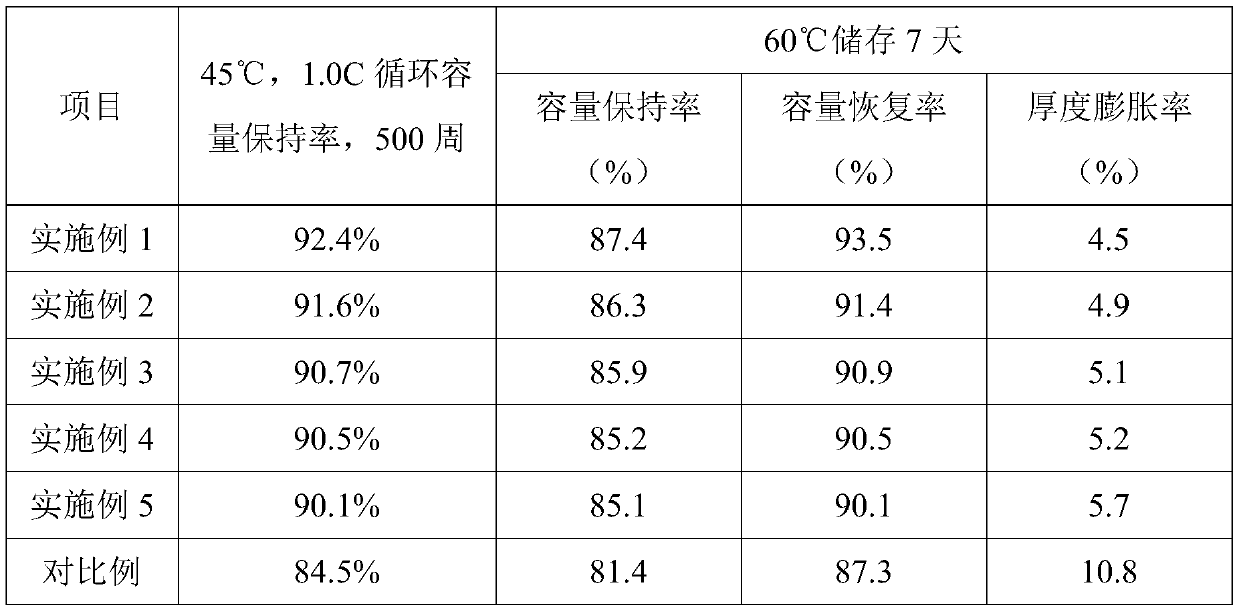

Embodiment 1

[0035] The graphite composite negative electrode material of this embodiment is a core-shell structure, including an inner core, an outer shell, and a sodium fluoride composite material layer coated on the surface of the outer shell. The inner core is graphite, and the outer shell is a nitrogen-phosphorus-doped composite material layer. The heterocomposite material layer is formed by adding raw graphite into a nitrogen-containing ionic liquid dispersed with phosphorus-containing organic compounds, surfactants, and lithium salts, and sintering; the phosphorus-containing organic compounds, surfactants, lithium salts, and nitrogen-containing ions The mass ratio of the liquid is 30:3:3:200; the sodium fluoride composite material layer is mainly made of sodium fluoride, surfactant and binding agent, and the sodium fluoride, surfactant and binding agent The mass ratio is 8:3:3. The SEM figure of the graphite composite negative electrode material of the present embodiment is shown in...

Embodiment 2

[0043] The graphite composite negative electrode material of this embodiment is a core-shell structure, including an inner core, an outer shell, and a sodium fluoride composite material layer coated on the surface of the outer shell. The inner core is graphite, and the outer shell is a nitrogen-phosphorus-doped composite material layer. The heterocomposite material layer is formed by adding raw graphite into a nitrogen-containing ionic liquid dispersed with phosphorus-containing organic compounds, surfactants, and lithium salts, and sintering; the phosphorus-containing organic compounds, surfactants, lithium salts, and nitrogen-containing ions The mass ratio of the liquid is 10:1:1:200; the sodium fluoride composite material layer is mainly made of sodium fluoride, surfactant and binding agent, and the sodium fluoride, surfactant and binding agent The mass ratio is 5:1:5.

[0044] The phosphorus-containing organic compound is ammonium polyphosphate, the surfactant is coconut o...

Embodiment 3

[0051] The graphite composite negative electrode material of this embodiment is a core-shell structure, including an inner core, an outer shell, and a sodium fluoride composite material layer coated on the surface of the outer shell. The inner core is graphite, and the outer shell is a nitrogen-phosphorus-doped composite material layer. The heterocomposite material layer is formed by adding raw graphite into a nitrogen-containing ionic liquid dispersed with phosphorus-containing organic compounds, surfactants, and lithium salts, and sintering; the phosphorus-containing organic compounds, surfactants, lithium salts, and nitrogen-containing ions The mass ratio of the liquid is 50:5:5:200; the sodium fluoride composite material layer is mainly made of sodium fluoride, surfactant and binding agent, and the sodium fluoride, surfactant and binding agent The mass ratio is 10:5:10.

[0052] The phosphorus-containing organic compound is melamine polyphosphate, the surfactant is sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com