A preparation method of nitrogen-doped low-temperature carbon nanofiber electrode material for supercapacitor

A carbon nanofiber and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low capacitor energy density, complex synthesis process, and low specific capacitance, and achieve good electrochemical performance , Increase the amount of nitrogen doping, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

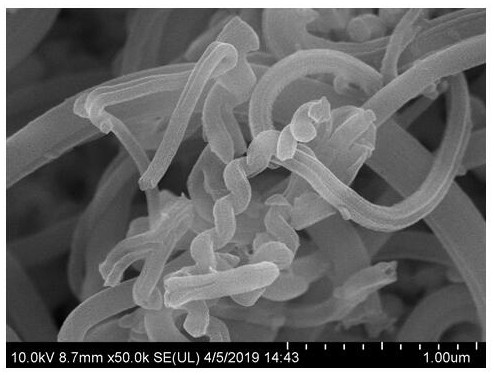

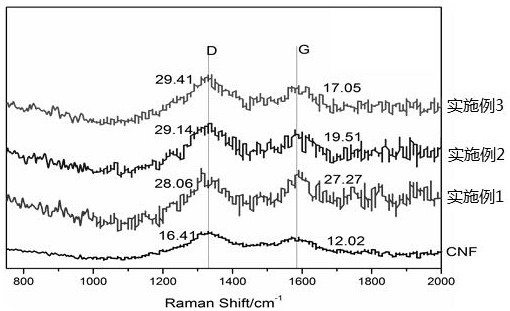

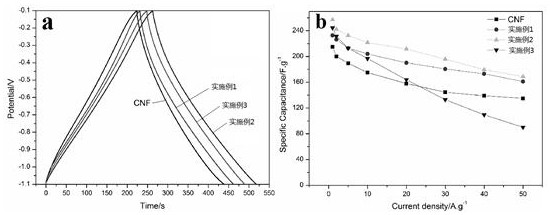

[0030] 1) Place the powder catalyst copper tartrate in a quartz boat, spread it evenly, and then place it in a heating tube, under the protection of high-purity nitrogen, raise the temperature to 240 ° C, feed acetylene, and keep it warm for 1 hour, and wait for the reaction After finishing, cool down to room temperature under the protection of nitrogen, take out the sample, and obtain low-temperature carbon nanofibers.

[0031] 2) Accurately weigh the low-temperature carbon nanofibers obtained in step 1) and KOH at a mass ratio of 1:1, heat up to 800°C under the protection of high-purity nitrogen, activate for 1 hour, add a large amount of distilled water, and filter through a sand core funnel to obtain precipitate, and repeatedly wash the precipitate with distilled water and absolute ethanol until the solution becomes neutral, and finally dry it in a vacuum oven at 80° C. to obtain activated carbon nanofibers.

[0032] 3) Put the activated carbon nanofiber and melamine nitro...

Embodiment 2

[0035] 1) Place the powder catalyst copper tartrate in a quartz boat, spread it evenly, and then place it in a heating tube. Under the protection of high-purity nitrogen, the temperature rises to 260 ° C, and acetylene is introduced and kept for 1 hour until the reaction is completed. Afterwards, it was cooled to room temperature under the protection of nitrogen, and the samples were taken out to obtain low-temperature carbon nanofibers.

[0036] 2) Accurately weigh the low-temperature carbon nanofibers obtained in step 1) and KOH at a mass ratio of 1:2, heat up to 800°C under the protection of high-purity nitrogen, activate for 3 hours, add a large amount of distilled water, and filter through a sand core funnel to obtain precipitate, and repeatedly wash the precipitate with distilled water and absolute ethanol until the solution becomes neutral, and finally dry it in a vacuum oven at 80° C. to obtain activated carbon nanofibers.

[0037] 3) Put the activated carbon nanofiber...

Embodiment 3

[0040] 1) Put the powder catalyst copper tartrate in a quartz boat, spread it evenly, and then place it in a heating tube, under the protection of high-purity nitrogen, the temperature rises to 280 ° C, feed acetylene, and keep it warm for 1 hour, and wait for the reaction to complete Afterwards, it was cooled to room temperature under the protection of nitrogen, and the samples were taken out to obtain low-temperature carbon nanofibers.

[0041] 2) Accurately weigh the low-temperature carbon nanofibers obtained in step 1) and KOH at a mass ratio of 1:3, heat up to 800°C for 2 hours under the protection of high-purity nitrogen, add a large amount of distilled water, and filter through a sand core funnel to obtain precipitate, and repeatedly wash the precipitate with distilled water and absolute ethanol until the solution becomes neutral, and finally dry it in a vacuum oven at 80° C. to obtain activated carbon nanofibers.

[0042] 3) Put the activated carbon nanofiber and melam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com