A water-soluble triazole compound

A triazole compound, water-soluble technology, applied in the field of water-soluble triazole compound and its preparation, can solve the problems of difficult synthesis of water-soluble compounds, poor drug stability, etc., achieve excellent water solubility, improve solubility and stability , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

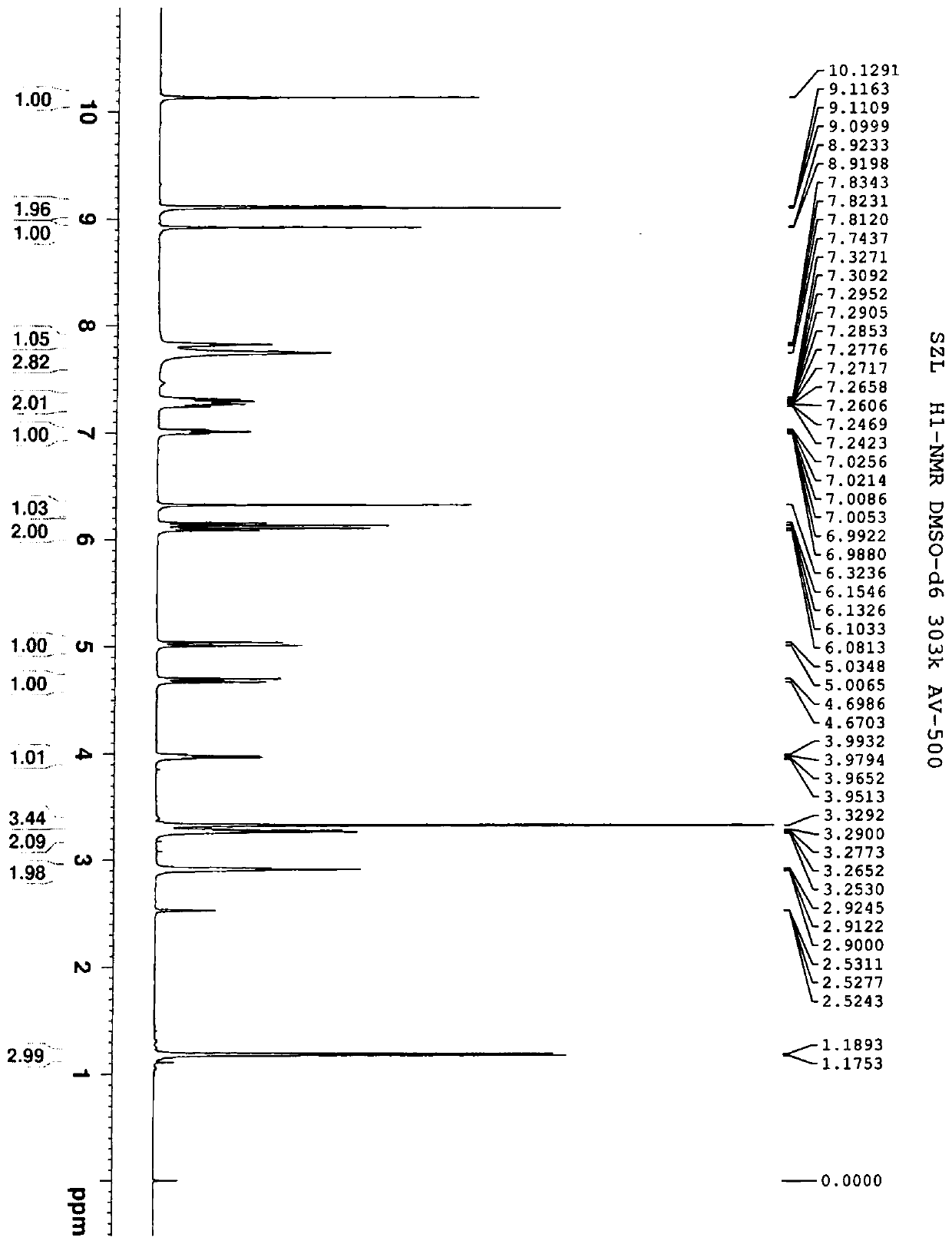

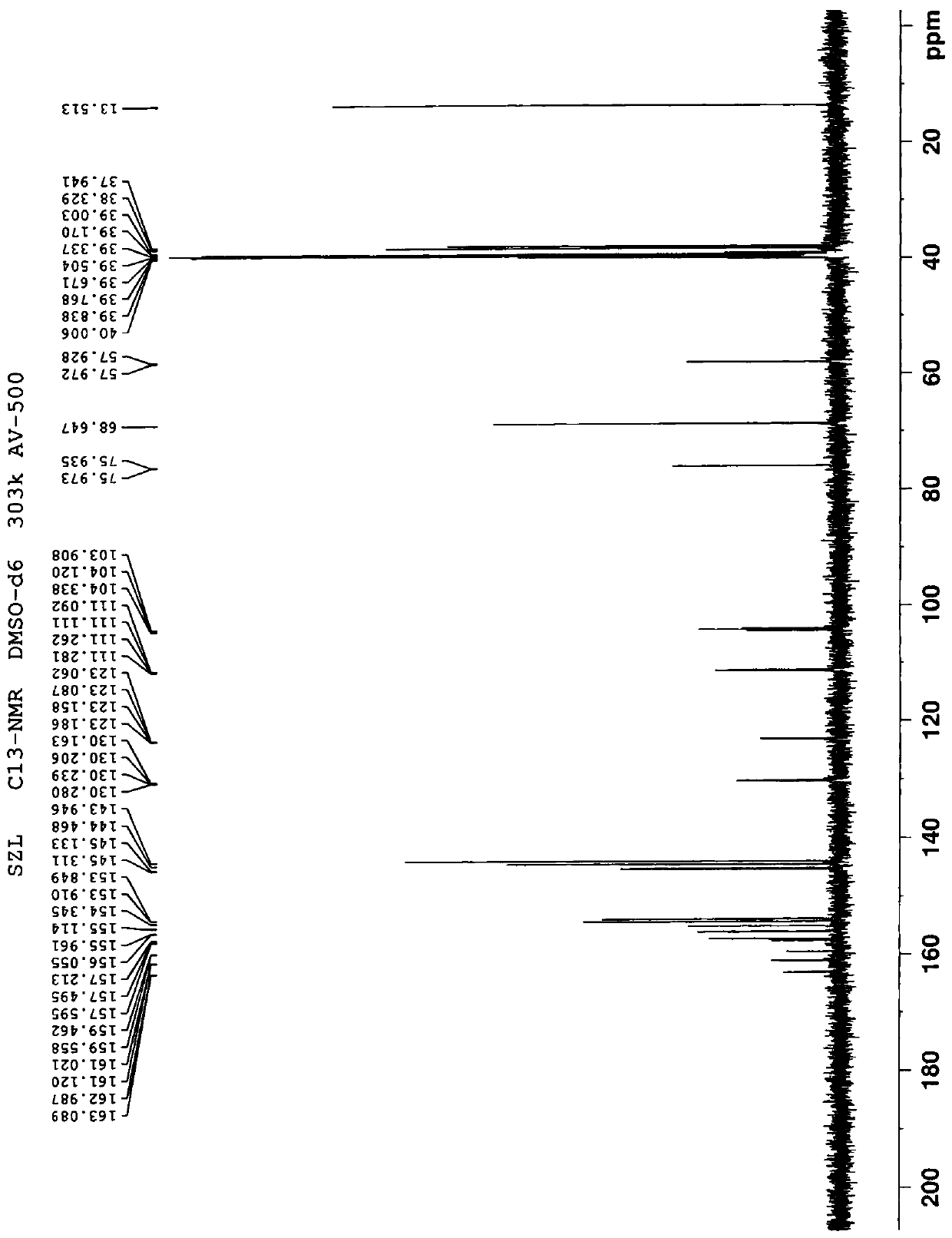

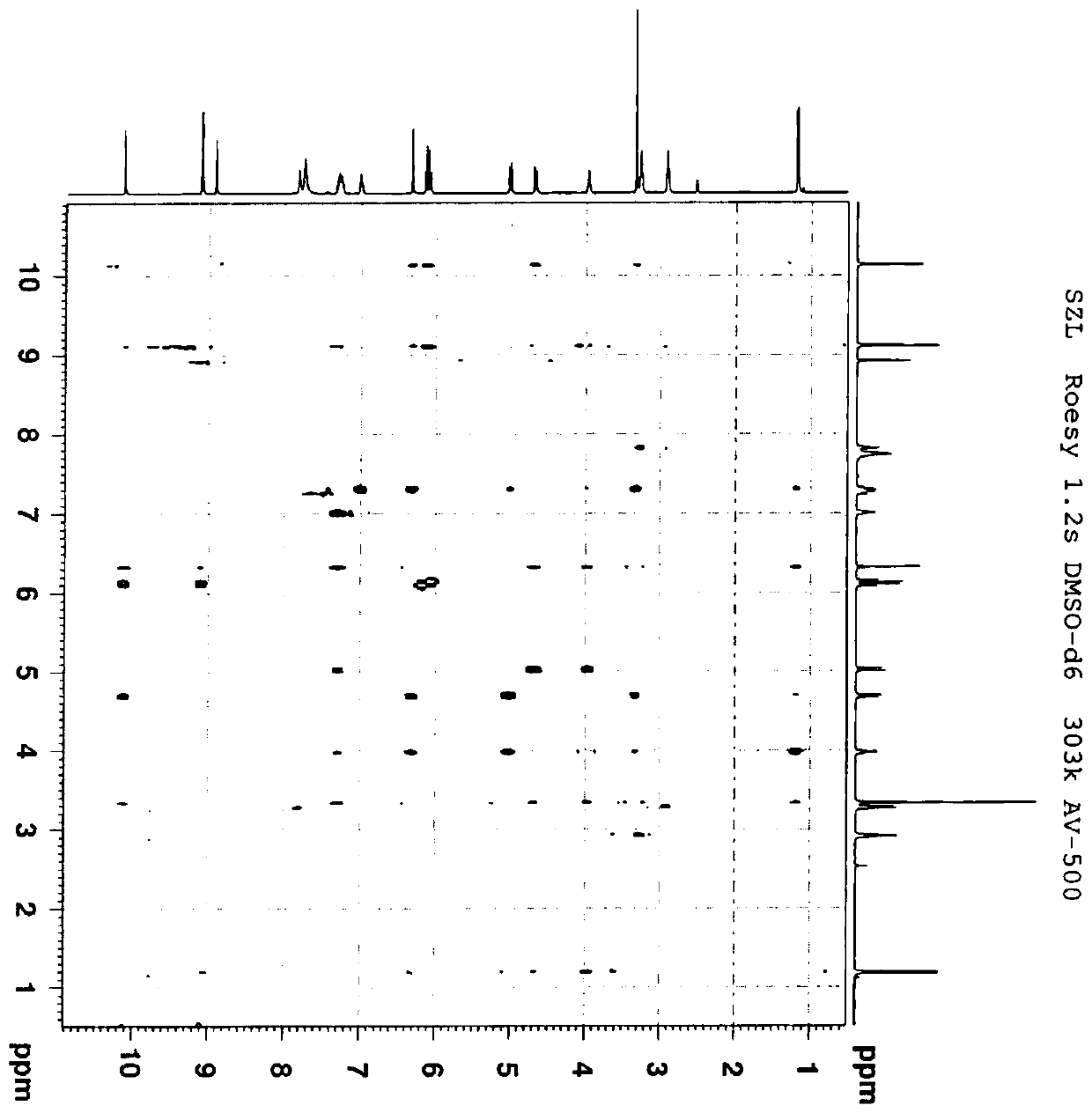

[0039] Example 1 Synthesis of Compound 3

[0040] Chemical reaction formula:

[0041]

[0042] Steps:

[0043] In a 500 mL reaction flask, add 20 g of compound a and 200 mL of dichloromethane, stir, and then add 12.8 g of pyridine. Then 17.7 g of chloromethyl chloroformate was added dropwise at 10-20°C, after the dripping was completed, the temperature was raised to 20-25°C for 24 hours. Add 100 mL of water to the reaction solution, stir and separate the layers, and then wash the organic layer with 80 mL×2 with water. Collect the organic layer, dry over anhydrous sodium sulfate, and concentrate to dryness under reduced pressure to obtain 27.4 g of oil, which is compound 1. The yield was 87%.

[0044] In a 1L reaction flask, add 27.4g of compound 1, 23.4g of potassium iodide and 410mL of acetonitrile, stir, and then add 37.8g of compound X (voriconazole), and heat to reflux for 15h. Stop the reaction, cool to 20-25°C, filter to remove insoluble materials, and concentrate the filtrat...

Embodiment 2

[0050] Example 2 Synthesis of Compound 6

[0051] Chemical reaction formula:

[0052]

[0053] Steps:

[0054] In a 250 mL reaction flask, add 10 g of compound b and 100 mL of dichloromethane, stir, and then add 13.7 g of pyridine. Then 18.9 g of chloromethyl chloroformate was added dropwise at 10-20°C, and after the dripping was completed, the temperature was raised to 20-25°C for 24 hours. Add 50 mL of water to the reaction solution, stir and separate the layers, and then wash the organic layer with 30 mL×2 of water. Collect the organic layer, dry over anhydrous sodium sulfate, and concentrate to dryness under reduced pressure to obtain 18.9 g of oil, which is compound 4. The yield was 84%.

[0055] In a 500 mL reaction flask, add 18.9 compound 4, 24.3 g potassium iodide and 285 mL acetonitrile, stir, then add 39.3 g compound X (voriconazole), and heat to reflux for 15 hours. Stop the reaction, cool to 20-25°C, filter to remove insoluble materials, and concentrate the filtrate to...

Embodiment 3

[0059] Example 3 Synthesis of Compound 9

[0060] Chemical reaction formula:

[0061]

[0062] Steps:

[0063] In a 500 mL reaction flask, add 20 g of compound c and 200 mL of dichloromethane, stir, and then add 14.7 g of pyridine. Then 17.6g of chloromethyl chloroformate was added dropwise at 10-20°C, after the dripping was completed, the temperature was raised to 20-25°C for 24h reaction. Add 100 mL of water to the reaction solution, stir and separate the layers, and then wash the organic layer with 80 mL×2 with water. Collect the organic layer, dry over anhydrous sodium sulfate, and concentrate to dryness under reduced pressure to obtain 26.8 g of oil, which is compound 7. The yield was 85%.

[0064] In a 1 L reaction flask, add 26.8 g of compound 7, 22.8 g of potassium iodide and 400 mL of acetonitrile, stir, and then add 36.8 g of compound X (voriconazole), and heat to reflux for 15 hours. Stop the reaction, cool to 20-25°C, filter to remove insoluble materials, and concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com