Hollow fiber ultra-filtration membrane preparation method

A technology of ultrafiltration membrane and fiber, applied in the field of ultrafiltration membrane, can solve the problems of consumption, high filtration resistance of ultrafiltration membrane, multi-kinetic energy, etc., and achieve the effect of high membrane flux, small membrane pore size, and high membrane strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

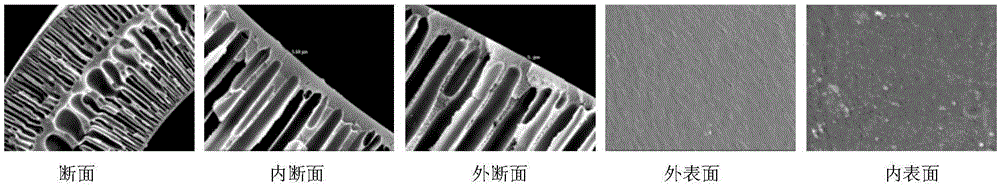

Embodiment 1

[0056] Preparation of casting solution: Weigh 70kg of dimethylacetamide (DMAc), 1kg of anhydrous lithium chloride, 5kg of polyethylene glycol (PEG600), 10kg of polyvinylpyrrolidone (K90), and 14kg of PVDF, and add them to 150L In the casting solution reaction kettle, and after adding materials, stir in the reaction kettle for 20 minutes, then add the next material, heat the casting solution reactor temperature to 95 ° C, and put the above casting solution system at 130 rpm Dissolve for 25 hours under separate conditions, and obtain a homogeneous casting solution system after vacuum and static defoaming for 36 hours.

[0057] The preparation of gelling agent in the gel bath: triethylene glycol, diethylene glycol are fully dissolved in deionized water, obtain the gelling agent of triethylene glycol concentration 28wt% and diethylene glycol concentration 12wt%, and the condensate of this composition The glue is used as the first gel bath, and the temperature of the first gel bath...

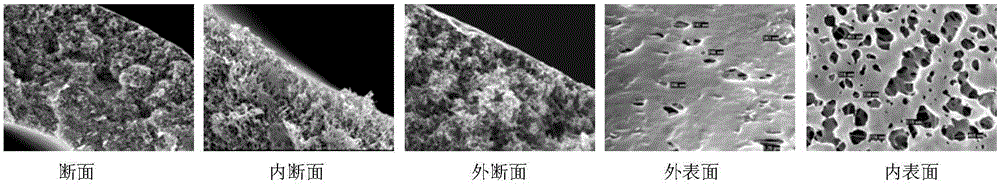

Embodiment 2

[0068] Preparation of casting solution Weigh 66kg of dimethylacetamide (DMAc), 2kg of anhydrous aluminum trichloride, 10kg of polyethylene glycol (PEG400), 8kg of polyvinylpyrrolidone (K30), 14kg of PES polymer, and add Into the 150L casting liquid reaction kettle, and after adding materials, stir in the reaction kettle for 20 minutes, then add the next substance, and add the next substance after fully stirring in the reaction kettle for 20 minutes, and react the casting solution The temperature of the kettle was heated to 100°C, and the above-mentioned casting solution system was dissolved at 130 rpm for 30 hours, and a homogeneous casting solution system was obtained after vacuum and static defoaming for 40 hours.

[0069] Preparation of the gelling agent in the gel bath: triethylene glycol and diethylene glycol are fully dissolved in deionized water to obtain a gelling agent with a triethylene glycol concentration of 28wt% and a diethylene glycol concentration of 12wt%. age...

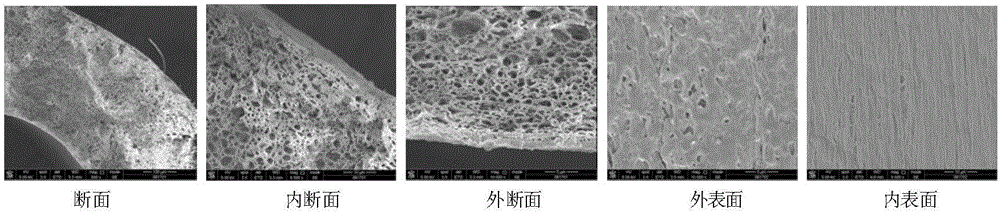

Embodiment 3

[0079] Preparation of casting solution: Weigh 56kg of nitrogen-methylpyrrolidone (NMP), 2kg of anhydrous aluminum trichloride, 8kg of polyethylene glycol (PEG600), 6kg of polyvinylpyrrolidone (K90), 18kg of PVDF polymer, and add in sequence Into the 150L casting solution reactor, and when adding materials, stir in the reactor for 20 minutes, then add the next material, heat the casting solution reactor temperature to 110°C, and put the above casting solution system at 130 Dissolve for 34 hours under the condition of rpm, and obtain a uniform casting solution system after vacuum and static defoaming for 42 hours.

[0080] Preparation of the gelling agent in the gel bath: triethylene glycol and diethylene glycol are fully dissolved in deionized water to obtain a gelling agent with a triethylene glycol concentration of 28wt% and a diethylene glycol concentration of 12wt%. agent as the first gel bath, and the temperature of the first gel bath is raised to 95°C; the aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com