Method for preparing Ni2P catalyst with three-dimensional cascade pore structures at low temperature

A technology of stepped pores and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of not having a stepped pore structure, and achieve obvious advantages, mild preparation conditions, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of Ni with three-dimensional hierarchical pore structure prepared at low temperature 2 The method of P catalyst, comprises steps as follows:

[0043] 1) Weigh 0.1 g of Ni-MOF-74 precursor and 2.0 g of sodium hypophosphite and place them on both ends of the corundum porcelain boat respectively, put the porcelain boat into a tube furnace, and pass in argon with a flow rate of 100 ml per minute Gas, evacuate the air in the tube furnace;

[0044] 2) Heating to 275 degrees Celsius at a heating rate of 5 degrees Celsius per minute, and holding at this temperature for 180 minutes (continuously using 100 ml per minute of argon purging during the process), you can get a Ni with a three-dimensional hierarchical pore structure. 2 P catalyst.

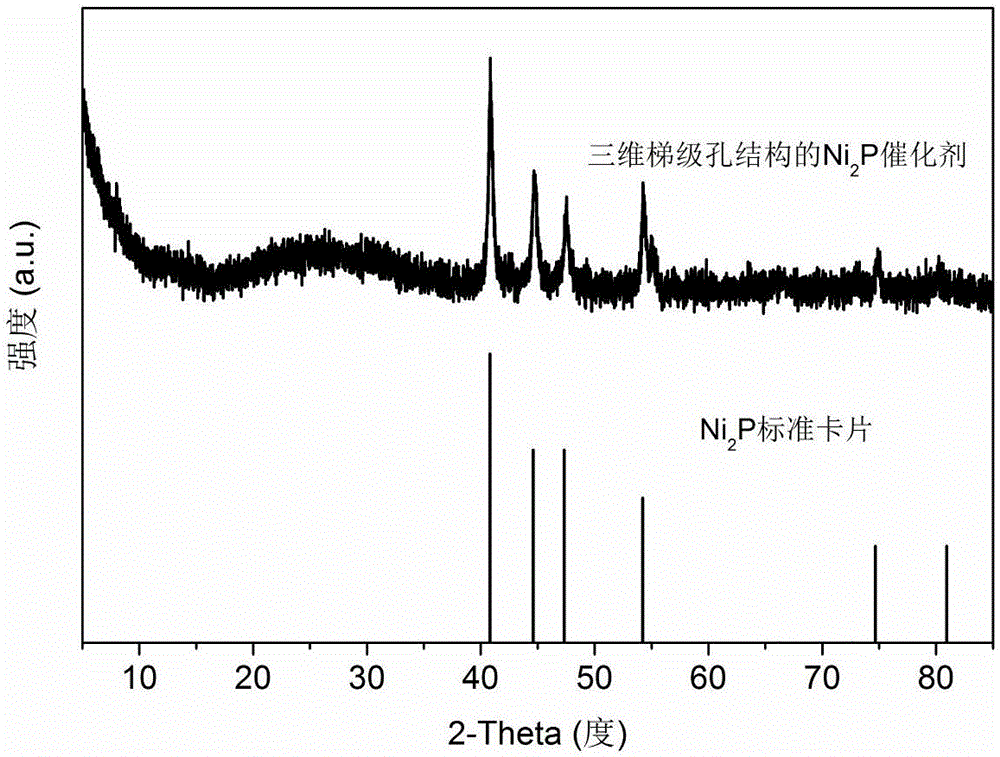

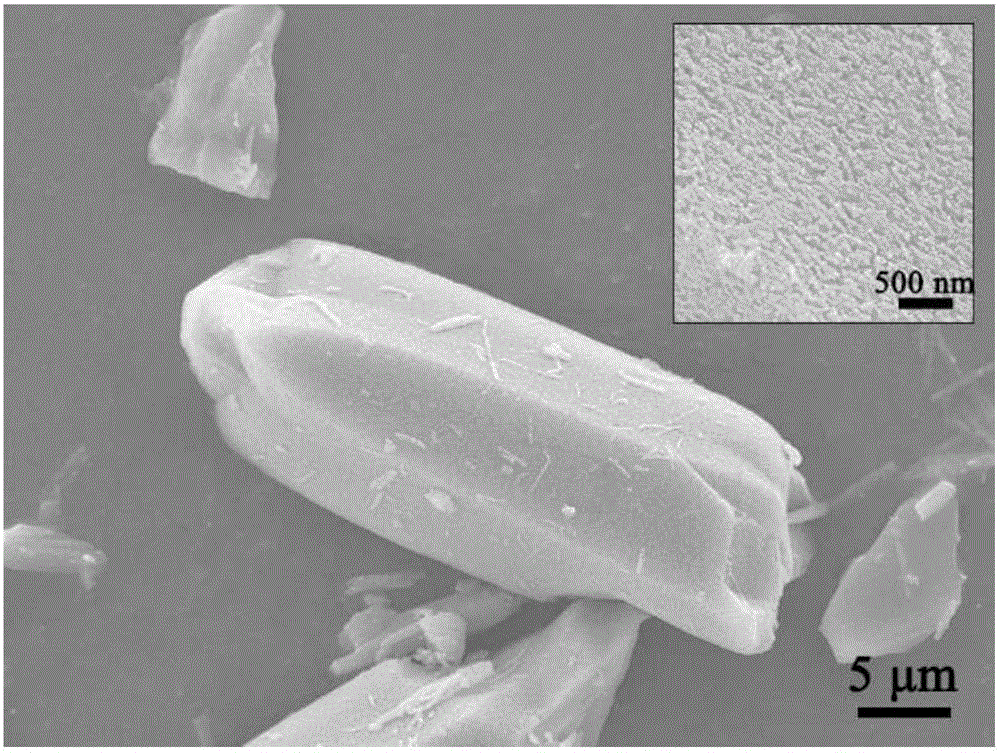

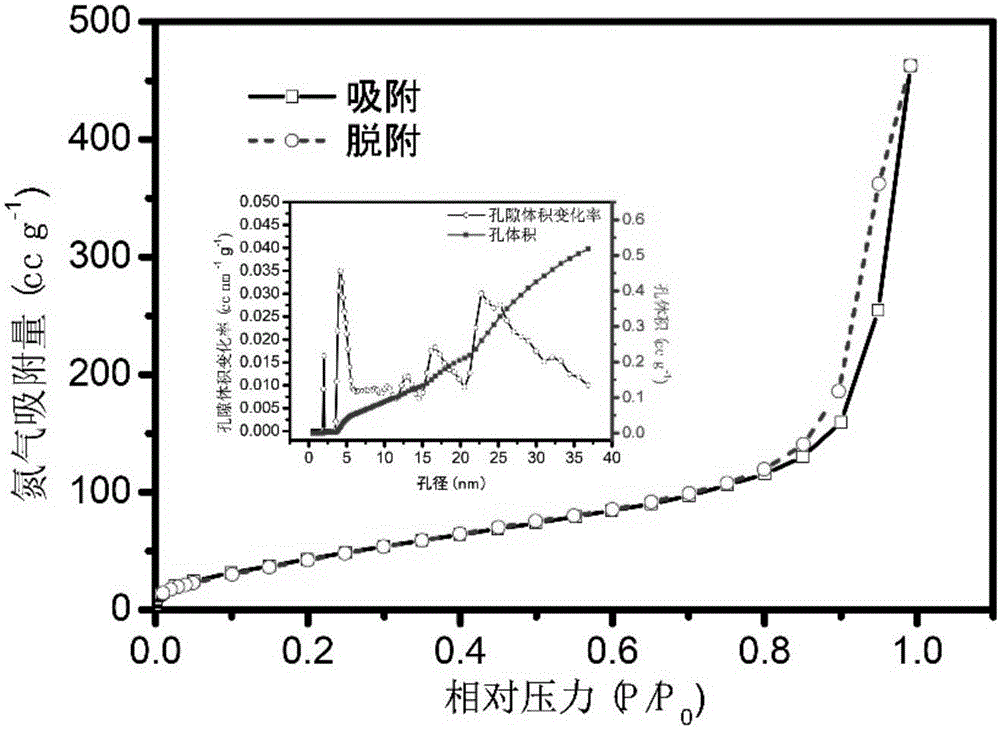

[0045] figure 1 It is the Ni of the three-dimensional stepped pore structure prepared in this embodiment. 2 X-ray powder diffraction pattern (PXRD) of P catalyst. Depend on figure 1 It can be seen that the prepared Ni 2 P is a ...

Embodiment 2

[0052] A kind of Ni with three-dimensional hierarchical pore structure prepared at low temperature 2 The method of P catalyst, comprises steps as follows:

[0053] 1) Weigh 0.1 g of Ni-MOF-74 precursor and 3.0 g of sodium hypophosphite and place them on both ends of the corundum porcelain boat respectively, put the porcelain boat into a tube furnace, and pass in argon with a flow rate of 100 ml per minute Gas, evacuate the air in the tube furnace;

[0054] 2) Heating to 300 degrees Celsius at a heating rate of 5 degrees Celsius per minute, and holding at this temperature for 200 minutes (continuously using 100 ml per minute of argon purging during the process), you can get a Ni with a three-dimensional hierarchical pore structure. 2 P catalyst.

Embodiment 3

[0056] A kind of Ni with three-dimensional hierarchical pore structure prepared at low temperature 2 The method of P catalyst, comprises steps as follows:

[0057] 1) Weigh 0.1 g of Ni-MOF-74 precursor and 1.0 g of sodium hypophosphite and place them on both ends of the corundum porcelain boat respectively, put the porcelain boat into the tube furnace, and pass in argon with a flow rate of 100 ml per minute Gas, evacuate the air in the tube furnace;

[0058] 2) Heating to 275 degrees Celsius at a heating rate of 5 degrees Celsius per minute, and keeping it at this temperature for 120 minutes (continuously using 100 ml per minute of argon purging during the process), you can get a Ni with a three-dimensional hierarchical pore structure. 2 P catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com