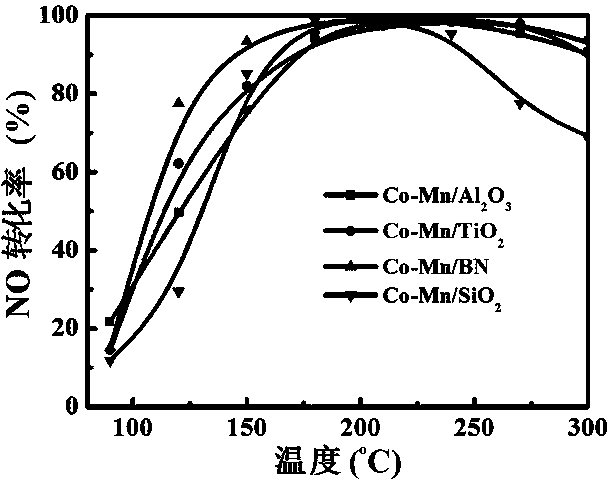

Preparation method of composite oxide denitration catalyst with hexagonal boron nitride as carrier

A hexagonal boron nitride and composite oxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The effect of widening the operating temperature window, high catalytic activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Hexagonal boron nitride was pretreated in concentrated nitric acid at 60°C for 3 hours, the suspension was filtered off, washed with deionized water until the pH value reached 7, and then the obtained precipitate was dried at 100°C. Take 2g of pretreated hexagonal boron nitride and add it into a 50ml flask containing a certain amount of deionized water, and stir at room temperature for 30min. The manganese acetate of 0.3470g and the cobalt acetate precursor salt of 1.0588g are joined in the beaker that contains 20ml deionized water, and the target makes the catalyst after calcining have the cobalt manganese ratio of 3:1, makes the quality of manganese oxide account for total mass 5%. Then, the prepared precursor salt solution was added into the flask containing hexagonal boron nitride, evaporated using a rotary evaporator for 3 hours, and dried in an oven at 80° C. for 18 hours. The product was taken out from the flask and ground in a mortar, then placed in a tube furn...

Embodiment 2

[0023] Hexagonal boron nitride was pretreated in concentrated nitric acid at 60°C for 3 hours, the suspension was filtered off, washed with deionized water until the pH value reached 7, and then the obtained precipitate was dried at 100°C. Take 2g of pretreated hexagonal boron nitride and add it into a 50ml flask containing a certain amount of deionized water, and stir at room temperature for 30min. The manganese acetate of 0.3470g and the cobalt acetate precursor salt of 0.3487g are joined in the beaker that contains 20ml deionized water, and the target makes the catalyst after calcining have the cobalt manganese ratio of 1:1, makes the quality of manganese oxide account for the total mass 5%. Then, the prepared precursor salt solution was added into the flask containing hexagonal boron nitride, evaporated using a rotary evaporator for 3 hours, and dried in an oven at 80° C. for 18 hours. The product was taken out from the flask and ground in a mortar, then placed in a tube ...

Embodiment 3

[0026] Hexagonal boron nitride was pretreated in concentrated nitric acid at 60°C for 3 hours, the suspension was filtered off, washed with deionized water until the pH value reached 7, and then the obtained precipitate was dried at 100°C. Take 2g of pretreated hexagonal boron nitride and add it into a 50ml flask containing a certain amount of deionized water, and stir at room temperature for 30min. The manganese acetate of 0.3470g and the cobalt acetate precursor salt of 0.6974g are joined in the beaker that contains 20ml deionized water, and the target makes the catalyst after calcining have the cobalt manganese ratio of 2:1, makes the quality of manganese oxide account for the total mass 5%. Then, the prepared precursor salt solution was added into the flask containing hexagonal boron nitride, evaporated using a rotary evaporator for 3 hours, and dried in an oven at 80° C. for 18 hours. The product was taken out from the flask and ground in a mortar, then placed in a tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com