Aromatic aldehyde/chitosan non-covalent modified carbon nano-tube composite material

A non-covalent modification, carbon nanotube technology, applied in the direction of carbon compounds, non-metallic elements, inorganic chemistry, etc., can solve the problems of harsh reaction conditions and destroy the rigid structure of carbon nanotubes, and achieve mild reaction conditions, simple process, The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 chitosan pretreatment.

[0030] Take 1g of chitosan powder and place it in 20mL of alcohol solution, sonicate for 1h, and swell with magnetic stirring for 12h.

Embodiment 2

[0031] Example 2 Cinnamaldehyde grafted chitosan.

[0032] Cinnamaldehyde grafted chitosan: measure cinnamaldehyde with a mass ratio of 4:1 to free amino groups in chitosan in ethanol, the concentration of the mixture is 50%, mix well and add to chitosan drop by drop In the methanol solution of sugar, react in a constant temperature water bath at 45°C for 8 hours, filter with suction, wash with absolute ethanol three times, and dry in vacuum for 24 hours. The obtained product is cinnamaldehyde-grafted chitosan.

Embodiment 3

[0033] Example 3 Characterization of cinnamaldehyde-grafted chitosan.

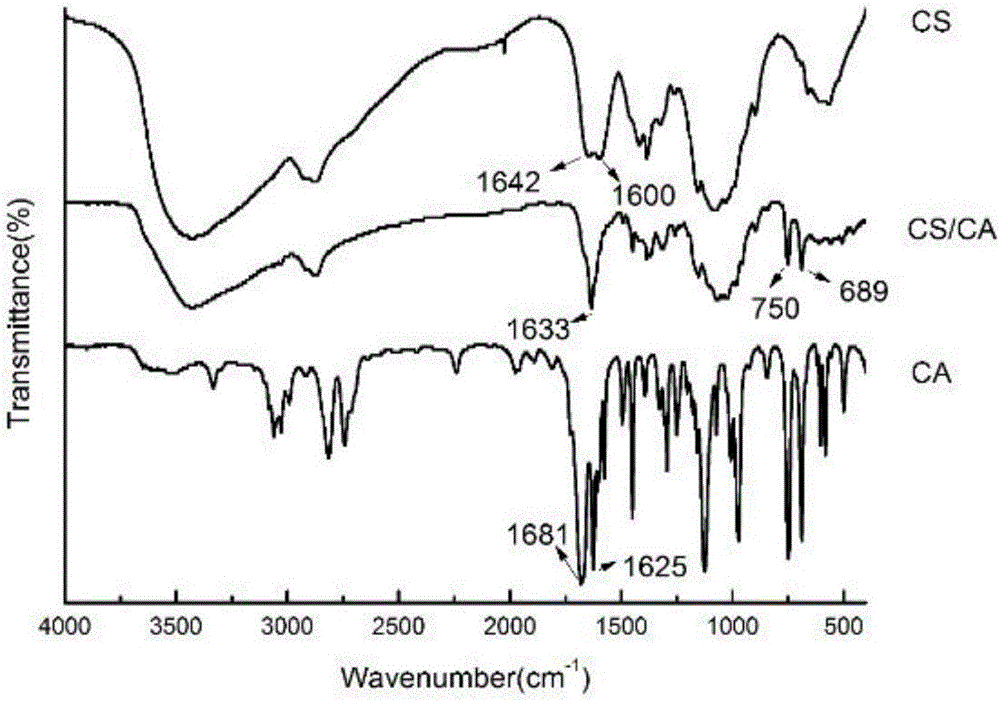

[0034] Curve CS shows the infrared spectrum of chitosan, 3200-3600cm -1 The broad peak is the overlapping peak of O-H bond stretching vibration peak and -N-H bond stretching vibration peak; 1642cm -1 It belongs to the stretching vibration of the C=O bond in the residual acetyl, which is the amide I band; 1600cm -1 Bending vibration belonging to N-H bond; 1153cm -1 and 1068cm -1 Stretching vibration at C-O-C; 896cm -1 is the structural swing peak of chitosan.

[0035] Curve CA shows the IR spectrum of cinnamaldehyde, 1681 cm -1 It belongs to the stretching vibration of the C=O bond in the aldehyde group, 1625cm -1 The weak peak is the stretching vibration peak of C=C bond, 1495cm -1 and 1449cm -1 The characteristic absorption peak of the benzene ring.

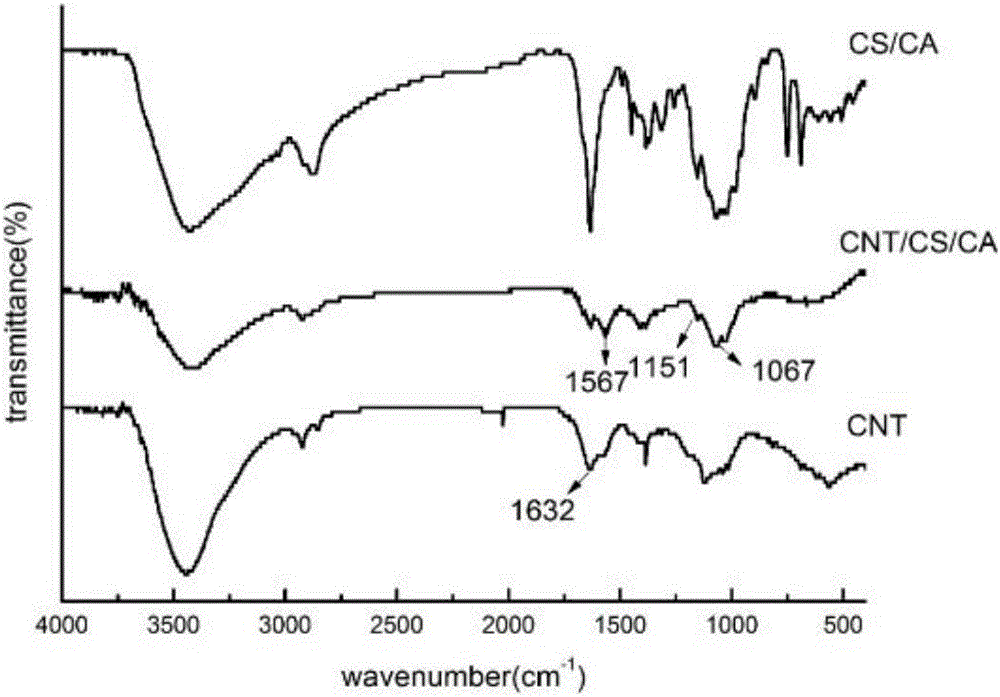

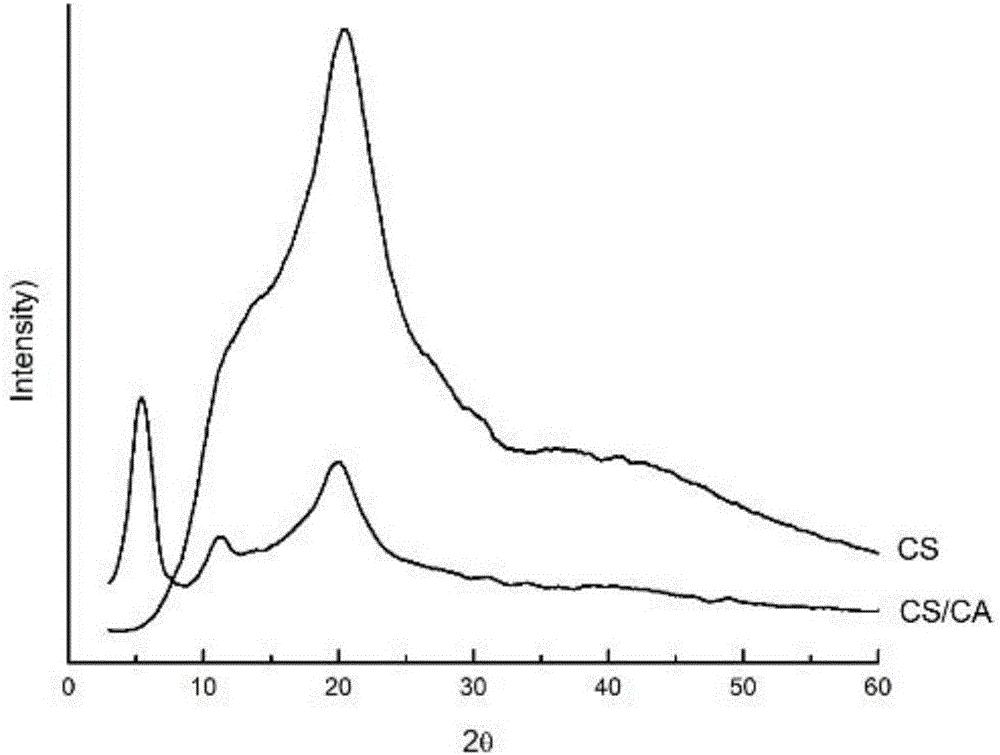

[0036] Curve CA / CS shows the infrared spectrum of cinnamaldehyde grafted chitosan, by comparing with chitosan infrared spectrum, it can be seen tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com