Bio-organic fertilizer prepared from soy protein wastewater sludge and preparation method of bio-organic fertilizer

A soybean protein wastewater and bio-organic fertilizer technology, which is applied in the preparation of organic fertilizers, sewage/sludge fertilizers, organic fertilizers, etc., can solve problems such as pollution and protein sludge treatment difficulties, and achieve the promotion of plant growth and high nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

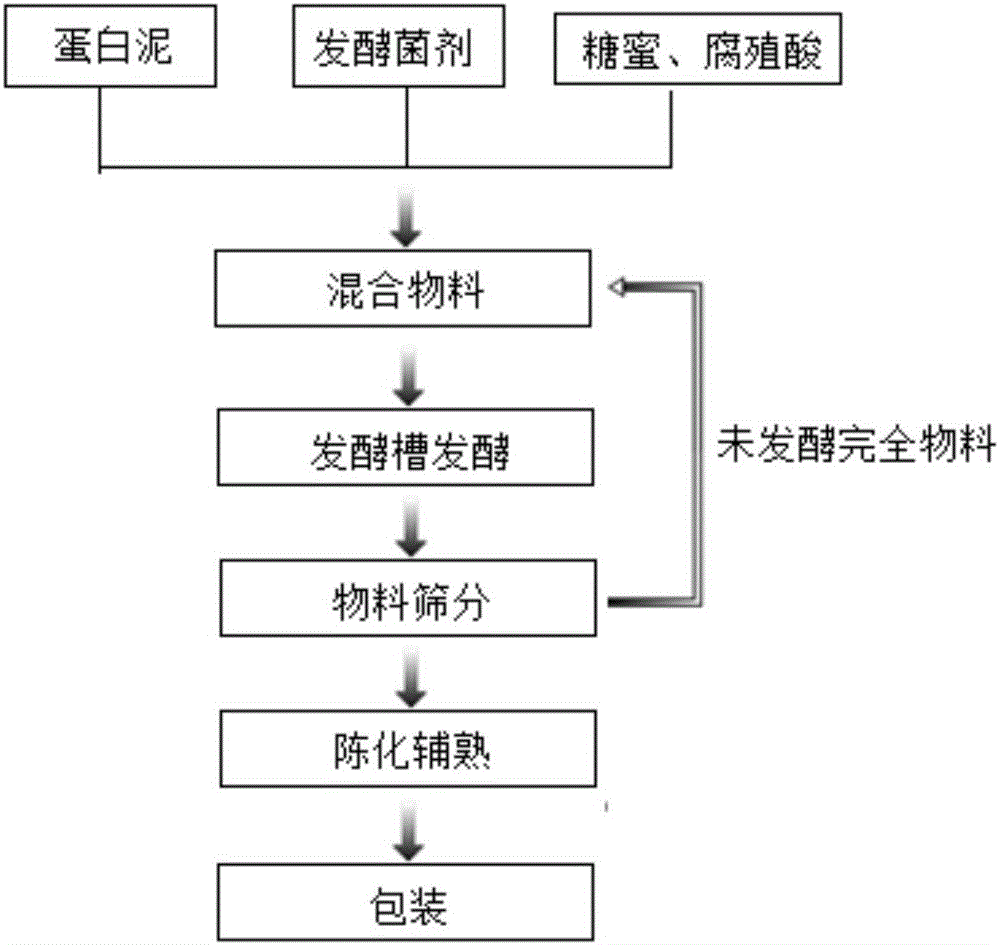

Image

Examples

Embodiment 1

[0033] Bio-organic fertilizer described in the present embodiment is prepared according to the following method:

[0034] (1) Add the preserved Bacillus stearothermophilus, Streptomyces albicans, Candida gravidarum and Staphylococcus epidermidis into the above-mentioned culture medium for aseptic culture for 48 hours respectively to obtain culture solutions containing various strains respectively, and take the above-mentioned The culture solution of Bacillus stearothermophilus, Streptomyces albicans, Candida gracilis and Staphylococcus epidermidis is mixed according to the ratio of 1:4:1:3 in mass ratio to obtain the required fermentation agent, and set aside;

[0035] (2) get protein sludge 30kg, step (1) in the fermented bacterial agent 5kg that makes, sugar beet molasses 3kg and humic acid 15kg mix and stir;

[0036] (3) Put the mixed materials into the fermentation tank, control the temperature at 30-40°C and introduce oxygen for aerobic fermentation; during the fermentati...

Embodiment 2

[0039] Bio-organic fertilizer described in the present embodiment is prepared according to the following method:

[0040](1) Add the preserved Bacillus stearothermophilus, Streptomyces albicans, Candida gravidarum and Staphylococcus epidermidis into the above-mentioned culture medium for aseptic culture for 48 hours respectively to obtain culture solutions containing various strains respectively, and take the above-mentioned The culture solution of Bacillus stearothermophilus, Streptomyces albicans, Candida gracilis and Staphylococcus epidermidis is mixed according to the ratio of 3:2:2:2 in mass ratio to obtain the required fermentation agent, and set aside;

[0041] (2) get protein sludge 50kg, step (1) in the fermented bacterial agent 2kg that makes, sugarcane molasses 8kg and humic acid 5kg mix and stir;

[0042] (3) Put the mixed materials into the fermentation tank, control the temperature at 30-40°C and introduce oxygen for aerobic fermentation; during the fermentation ...

Embodiment 3

[0045] Bio-organic fertilizer described in the present embodiment is prepared according to the following method:

[0046] (1) Add the preserved Bacillus stearothermophilus, Streptomyces albicans, Candida gravidarum and Staphylococcus epidermidis into the above-mentioned culture medium for aseptic culture for 48 hours respectively to obtain culture solutions containing various strains respectively, and take the above-mentioned The culture solution of Bacillus stearothermophilus, Streptomyces albicans, Candida gracilis and Staphylococcus epidermidis is mixed according to the ratio of 2:3:1:2 in mass ratio to obtain the required fermentation agent, and set aside;

[0047] (2) Get 40kg of protein sludge, 3kg of fermented bacterial agent prepared in step (1), 6kg of molasses (the mass ratio of sugarcane molasses and beet molasses is 1:1) and 10kg of humic acid and mix and stir evenly;

[0048] (3) Put the mixed materials into the fermentation tank, control the temperature at 30-40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com