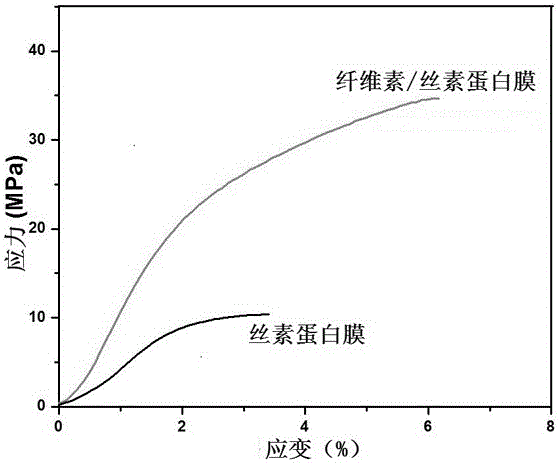

Nano-cellulose reinforced silk fibroin composite material and preparation method thereof

A technology of nano-cellulose and composite materials, applied in the field of nano-cellulose-reinforced silk fibroin composite materials and its preparation, which can solve the problems of complex process, easy aggregation of cellulose nano-whiskers, and difficulty in dispersing fibers, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Immerse 100 g silkworm silk in 5 L of 0.05% NaCO 3 solution, boiled at 98-100°C for 30 min, and repeated three times to degumming the silk, fully washed and dried to obtain pure silk fibroin fibers; solution, stirring and dissolving at 60°C for 55 min to obtain a silk fibroin mixed solution;

[0035] Add 1 g of microcrystalline cellulose powder into 80 mL of 9.3 mol / L LiBr solution, stir and dissolve at 110°C for 55 min to obtain a cellulose solution;

[0036] Mix the silk fibroin solution and cellulose solution according to the mass ratio of silk fibroin and fiber 50:50, stir at 110°C for 5 minutes and mix evenly to obtain a silk fibroin / cellulose mixed solution, cool at room temperature to form a blended gel glue;

[0037] The above gel was soaked in 75% ethanol for 2 h, and then soaked in flowing deionized water for 48 h to remove LiBr;

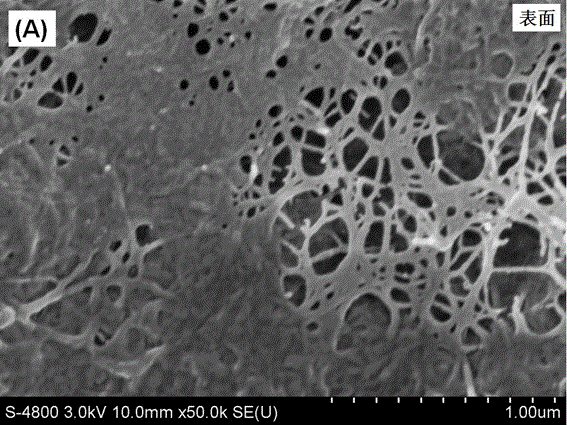

[0038] The purified silk fibroin / cellulose gel was dried in a vacuum oven at 37 °C for 48 h to obtain a nanocellulose-reinforce...

Embodiment 2

[0041] Add 20 g of degummed silk fibroin fibers to 100 mL of 10 mol / L LiBr solution, stir and dissolve at 60°C for 58 min to obtain a silk fibroin mixed solution;

[0042] Add 2 g of microcrystalline cellulose powder into 160 mL of 10 mol / L LiBr solution, stir and dissolve at 110°C for 58 min to obtain a cellulose solution;

[0043] Mix the silk fibroin solution and the cellulose solution according to the mass ratio of silk fibroin and fiber 20:80, stir at 110° C. for 3 minutes and mix evenly to obtain a silk fibroin / cellulose mixed solution. Cooling at room temperature to form a blended gel;

[0044] The above gel was soaked in 50% ethanol for 2 h, and then soaked in running water for 48 h to remove LiBr;

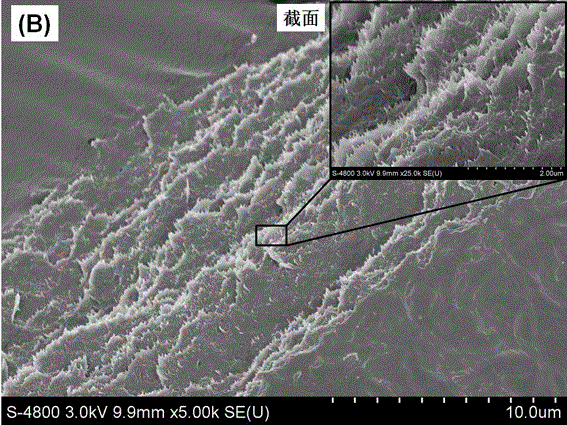

[0045] The purified silk fibroin / cellulose gel was dehydrated successively with 50%, 75% tert-butanol and anhydrous tert-butanol for 30 min, and then frozen at -20°C for 24 h to obtain frozen solids.

[0046] The above-mentioned frozen solid was freeze-dried for 48 h accor...

Embodiment 3

[0049] Add 10 g of degummed silk fibroin fibers to 40 mL of 8 mol / L LiBr solution, stir and dissolve at 60°C for 120 min to obtain a silk fibroin mixed solution;

[0050] Add 1 g of cellulose filter paper into 100 mL of 8 mol / L LiBr solution, stir and dissolve at 90 °C for 4 h to obtain a cellulose solution;

[0051] Mix the silk fibroin solution and cellulose solution according to the mass ratio of silk fibroin and fiber 80:20, stir at 90°C for 5 min and mix well to obtain a silk fibroin / cellulose mixed solution; cool at room temperature to form a blended gel;

[0052] Soak the above gel in 90% methanol for 1 h, then soak in running water for 72 h to remove LiBr;

[0053] The purified silk fibroin / cellulose gel was dried in a vacuum oven at 37 °C for 48 h to obtain a nanocellulose-reinforced silk film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com