A high-efficiency infrared excitation up-conversion luminescent material and its preparation method

A luminescent material, infrared excitation technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as environmental pollution and toxic fluoride, and achieve the effect of improving luminous efficiency, good crystallinity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

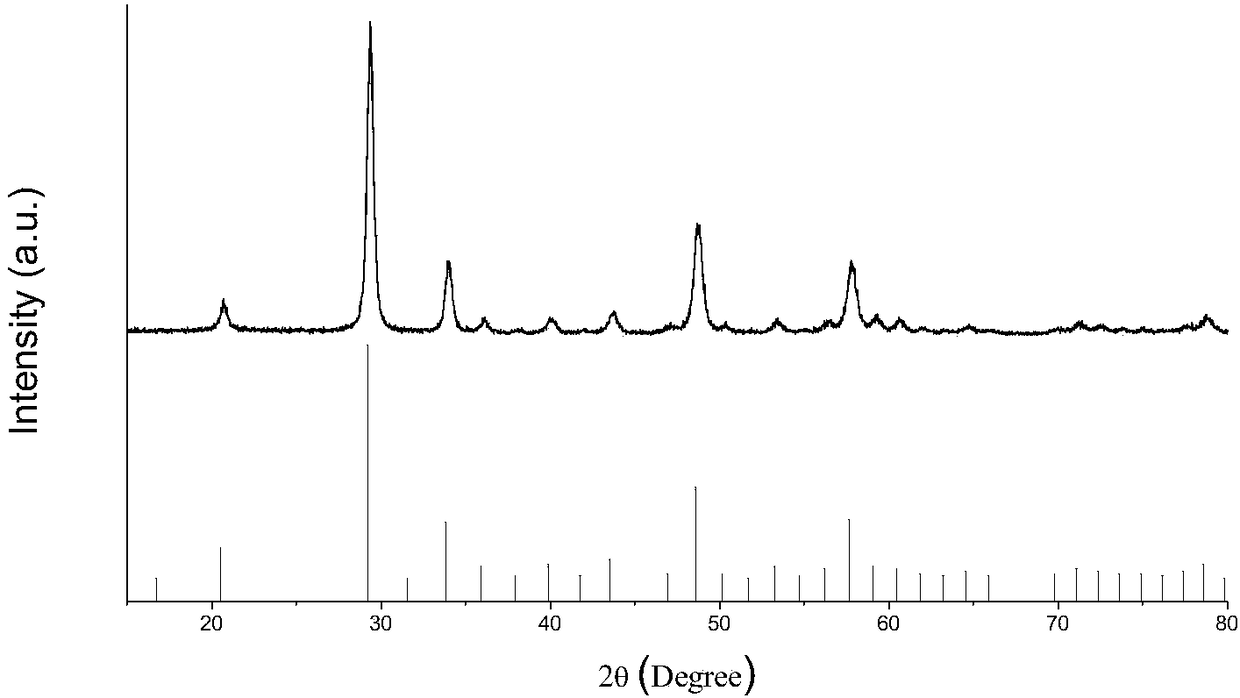

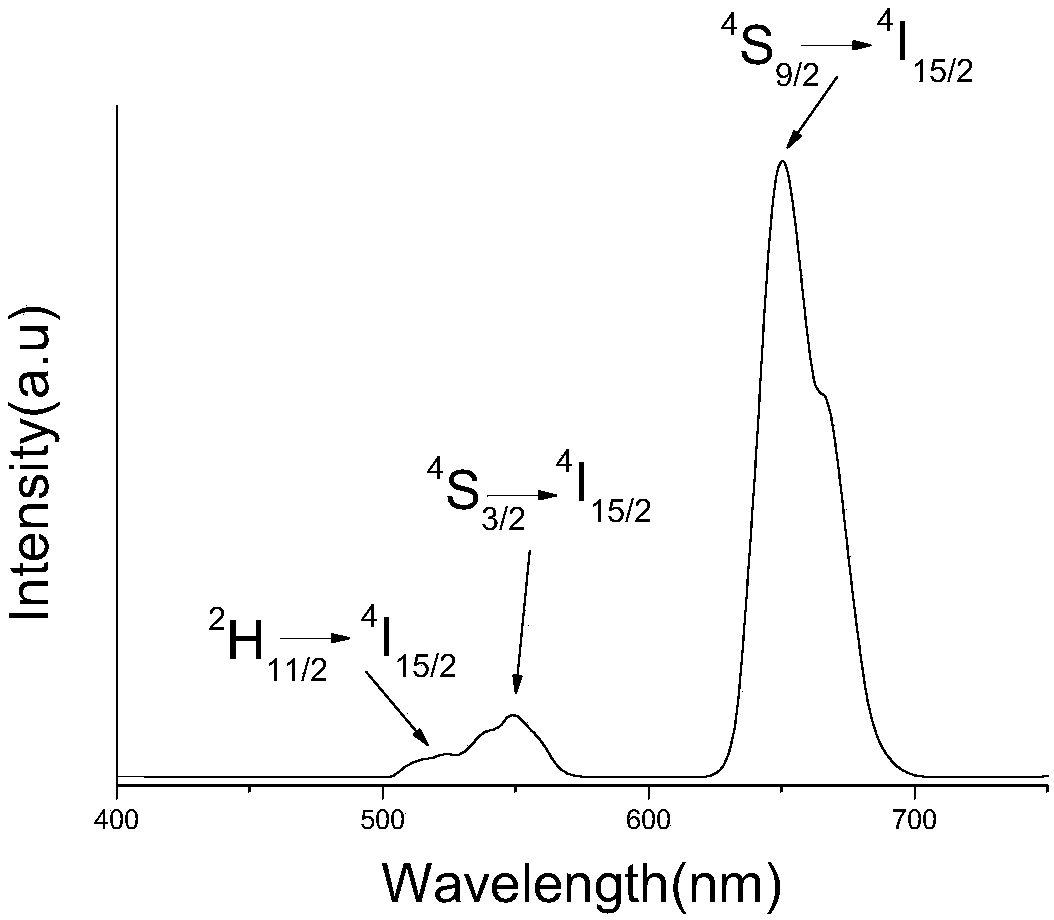

[0043] Dissolve 0.357g of hexamethylenetetramine in deionized water to prepare an alkaline solution, then add 0.6316g of yttrium nitrate, and stir thoroughly to obtain a transparent solution. Weigh a certain amount of yttrium nitrate and add it to the above solution, stir well to obtain a transparent solution with a molar ratio of Y:Er=97:3. Then it was placed in a reaction kettle and sealed, and kept at 180°C for 24 hours to obtain a white product. The cooled product was washed, filtered, and dried to obtain a white powder, and then calcined at 700° C. for 4 hours to obtain yttrium oxide crystals doped with erbium ions.

[0044] The obtained erbium-doped yttrium oxide crystals were characterized by XRD diffraction analysis, scanning electron microscope images and up-conversion luminescence spectra, and the characterization results are as follows: Figure 1-3 shown.

[0045] Scanning electron microscope images, such as figure 2 As shown, the morphology of the prepared yttr...

Embodiment 2

[0048] Dissolve 0.7g of urea in deionized water to prepare an alkaline solution, then add 0.6316g of yttrium nitrate, and stir thoroughly to obtain a transparent solution. Weigh a certain amount of erbium carbonate and add it to the above solution, stir well to obtain a transparent solution with a molar ratio of Y:Er=95:5. Then it was placed in a reaction kettle and sealed, and kept at 120°C for 10 hours to obtain a white product. The cooled product was washed, filtered, and dried to obtain a white powder, and then calcined at 500° C. for 3 hours to obtain yttrium oxide crystals doped with erbium ions.

Embodiment 3

[0050] Dissolve 0.7g of urea in deionized water to prepare an alkaline solution, then add 0.4316g of yttrium chloride, and stir thoroughly to obtain a transparent solution. Weigh a certain amount of erbium nitrate and add it to the above solution, stir well to obtain a transparent solution with a molar ratio of Y:Er=97:3. Then it was placed in a reaction kettle and sealed, and kept at 120°C for 10 hours to obtain a white product. The cooled product was washed, filtered, and dried to obtain a white powder, and then calcined at 500° C. for 2 hours to obtain yttrium oxide crystals doped with erbium ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com