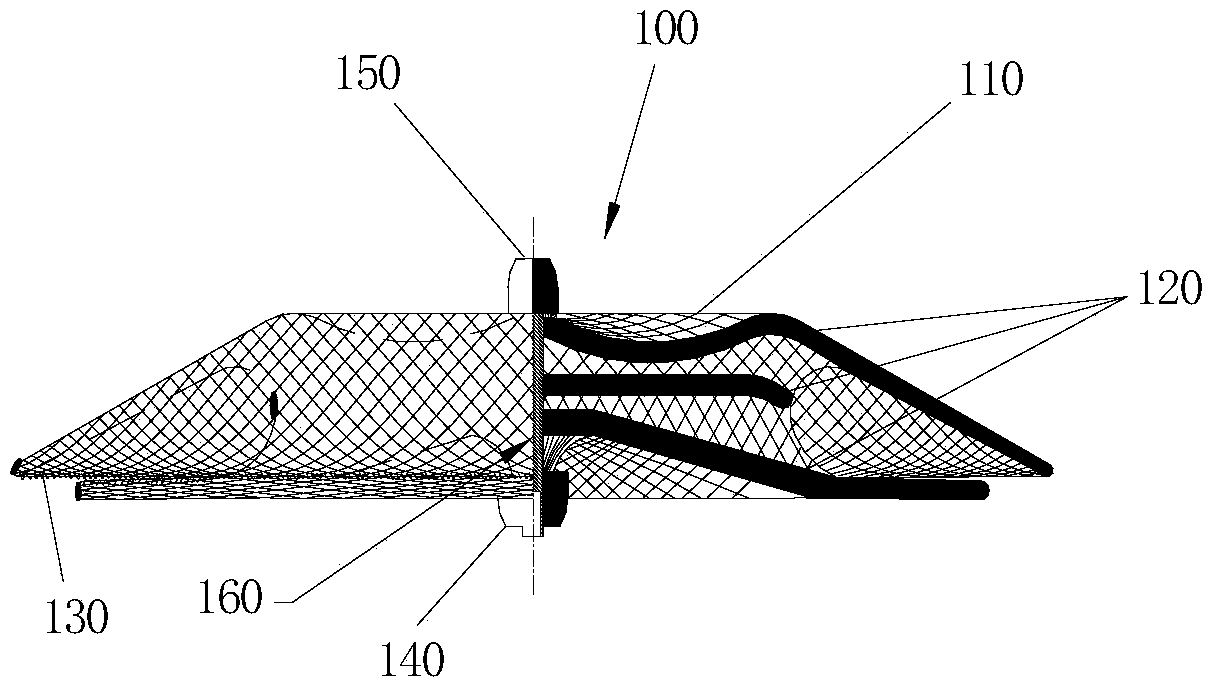

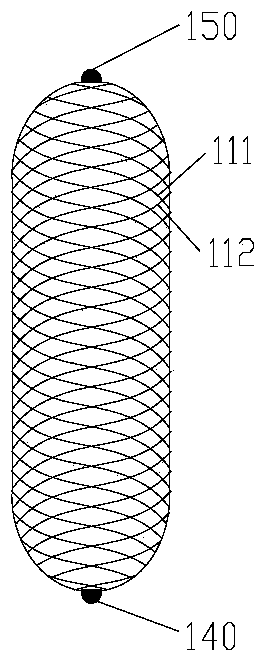

absorbable occluder

An occluder and polymer technology, applied in medical science, surgery, prosthesis, etc., can solve problems such as inflammatory reactions, achieve long degradation periods, and reduce release concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

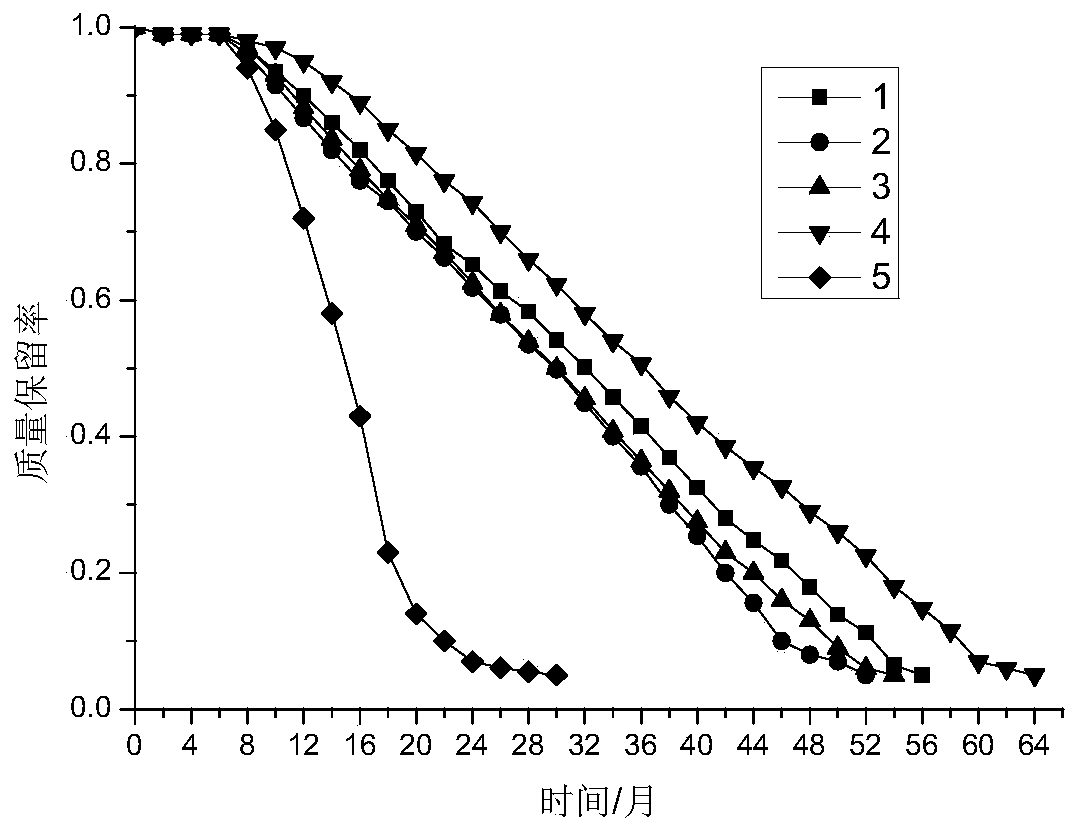

[0037] In the occluder provided in this embodiment, the overall mass of the braided mesh of the occluder is 0.726g. The braided net includes 96 poly-L-lactic acid (PLLA) filaments with a weight-average molecular weight of 100,000 Da and a polydispersity coefficient of 6.02, a filament diameter of 0.15 mm, and a crystallinity of 50%. The in vitro degradation experiment was carried out on PLLA silk. After 6 months of degradation, the elastic modulus measured was 2.66GPa, and the elongation at break was 70%. It has a stable frame structure within one month, so as to achieve complete endothelial coverage; the change trend of PLLA silk mass retention rate with time is as follows: image 3 As shown in curve 1, the degradation cycle is about 4 to 5 years, and the polymer mass retention rate drops less than 5% every 2 months in the 6th to 56th month, indicating that the degradation products are in the 6th to 56th month. After 2 years of implanting the occluder into the pig's heart, t...

Embodiment 2

[0039] In the occluder provided in this embodiment, the overall mass of the braided mesh of the occluder is 0.726g. The braided net includes 96 PLLA filaments with a weight average molecular weight of 100,000 Da, a polydispersity coefficient of 5.12, a crystallinity of 50%, and a filament diameter of 0.15 mm. In vitro degradation experiments were carried out on PLLA silk. After 6 months of degradation, the elastic modulus measured was 2.86GPa, and the elongation at break was 66%. This shows that the occluder made of PLLA silk in this embodiment can guarantee It has a stable frame structure within 6 months, so as to achieve complete endothelial coverage; the change trend of the quality retention rate of PLLA silk over time is as follows: image 3 As shown in the curve 2, the degradation period is 4 to 5 years, and the decrease of the polymer mass retention rate every 2 months in the 6th to 52nd month is less than 5%, indicating that the degradation product is in the 6th to 52nd...

Embodiment 3

[0041] In the occluder provided in this example, the braided mesh includes 200 polylactic-co-glycolic acid (PLGA) wires with a weight-average molecular weight of 50,000 Da and a polydispersity coefficient of 10, with a wire diameter of 0.50 mm and a crystallinity of 80. %. The in vitro degradation experiment was carried out on PLGA silk, and the elastic modulus measured after 6 months of degradation was 3.01GPa, and the elongation at break was 75%. It has a stable frame structure within one month, so as to achieve complete endothelial coverage; the decline of PLGA silk every two months from the 6th to 54th month is less than 5%, and the change trend of the quality retention rate of PLGA silk with time is as follows: image 3 As shown in the curve 3, the degradation products are released slowly in the 6th to 54th months; two years after the occluder implanted in the heart of pigs, the occluder and surrounding myocardial tissue were analyzed by pathological slices, and the patho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com