Preparation process of high-yield collagen fibers

A collagen fiber and preparation technology, which is applied in the field of high-yield collagen fiber preparation technology, can solve the problems of large-scale production, large-scale production, mixing of impurities, long extraction process cycle, etc., and achieve long bursting strength , saving production site, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

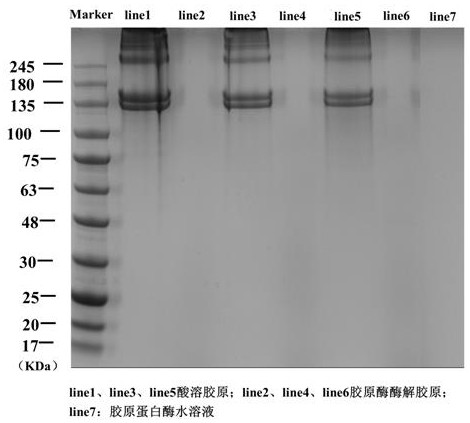

Image

Examples

Embodiment 1

[0069] The present embodiment provides a kind of preparation technology of high-yield collagen fiber, and described preparation technology comprises the following steps:

[0070] (1) Cutting: Select pigskin and cut it into thin slices to form tissue slices;

[0071] (2) Pre-treatment: Soak the tissue piece obtained in step (1) in a sodium chloride solution with a concentration of 1.5%, mix it for the first time with magnetic stirring, then wash with water to remove the sodium chloride solution, and pour it into the soaked tissue Add ethanol solution to the mixture, the concentration of the ethanol solution is 90wt%, magnetic stirring is carried out for the second mixing, and then the ethanol solution is removed by washing with water to form a pre-treated tissue;

[0072] (3) Enzyme reaction: Add 15wt% pretreated tissue to a weakly alkaline solution with a pH of 7.6, then add 10wt% trypsin from the pretreated tissue, react for 10 hours at 25°C, and add 1M The hydrochloric acid...

Embodiment 2

[0077] This embodiment provides a collagen fiber with high yield, and the preparation process includes the following steps:

[0078](1) Cutting: Select cowhide, cut into thin slices with length and width of 0.3-1.5mm to form tissue blocks;

[0079] (2) Pretreatment: Soak the tissue piece obtained in step (1) in a sodium chloride solution with a concentration of 1.5%, and mix for the first time at a ratio of 10ml of sodium chloride solution per gram of tissue, Stir magnetically at 25-37°C for 36 hours, then wash to remove the sodium chloride solution; add 5ml of ethanol solution with a concentration of 60wt% per gram of soaked tissue for the second mixing, and stir magnetically at 25-37°C After 12 hours, wash with water to remove the ethanol solution to form a pre-treated tissue;

[0080] (3) Enzyme reaction: Add 15wt% pre-treated tissue to an acidic solution with a pH of 2.5, then add 10wt% pepsin in the pre-treated tissue, react for 10 hours at 28°C, and add 1M hydroxide aft...

Embodiment 3

[0085] The present embodiment provides a kind of preparation technology of high-yield collagen fiber, and described preparation technology comprises the following steps:

[0086] (1) Cutting: Select bovine Achilles tendon and cut it into small cubic pieces of 0.3-1.0mm to form tissue blocks;

[0087] (2) Pretreatment: Soak the tissue piece or tissue block obtained in step (1) in 1.0% sodium chloride solution, and perform the first mixing at the ratio of adding 10ml of sodium chloride solution per gram of tissue, Stir magnetically at 25-37°C for 24 hours, then wash with water to remove the sodium chloride solution, add 10ml of ethanol solution with a concentration of 75wt% to each gram of soaked tissue for the second mixing, stir magnetically at 25-37°C for 24 hours, wash with water Remove the ethanol solution to form a pre-treated tissue;

[0088] (3) Enzyme reaction: In the acetic acid-sodium acetate buffer solution with a pH of 6.0, add 15wt% of the pretreated tissue obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com