Preparation method of nano meso-porous silicon composite hydrogel with controlled release function

A composite hydrogel and nano-mesoporous technology, which is applied in the direction of medical preparations of non-active ingredients, pharmaceutical formulas, inorganic non-active ingredients, etc., can solve the problem of reducing the drug release rate, and achieve good biocompatibility and biological Effects of degradability, clear pores and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

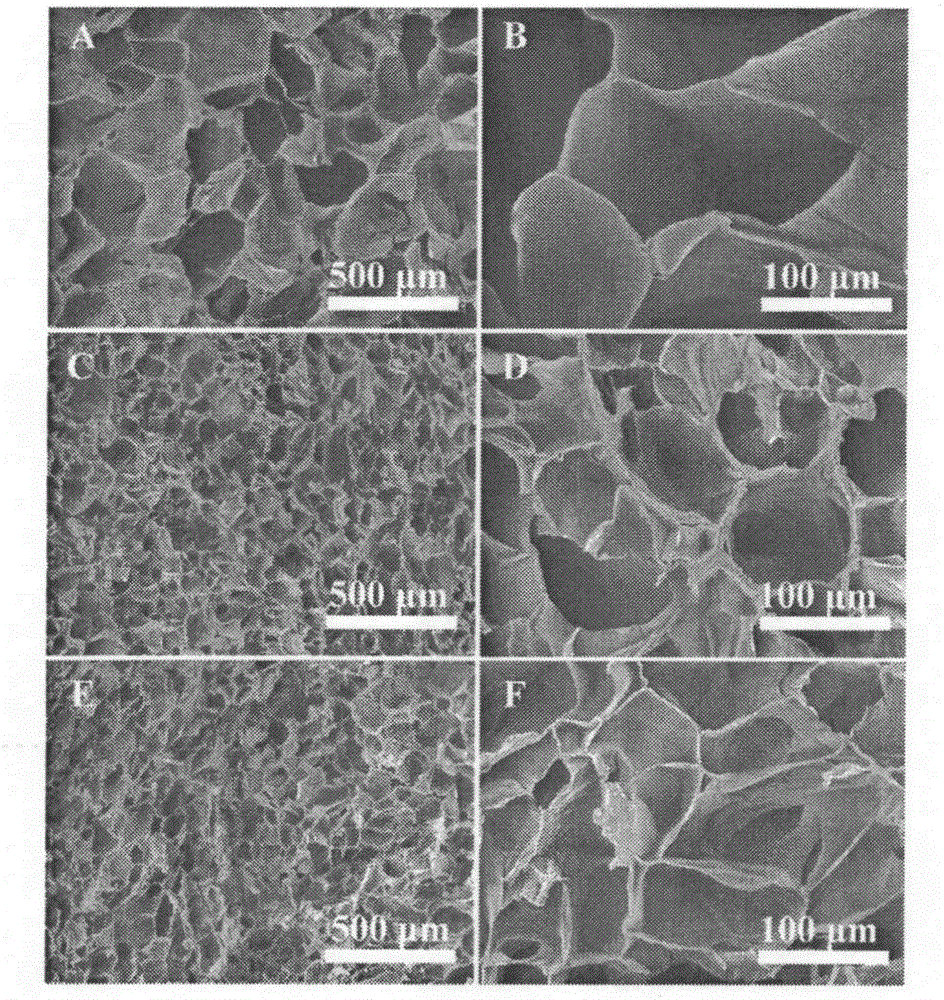

[0028] A preparation method of nanometer mesoporous silicon composite hydrogel with controlled release function:

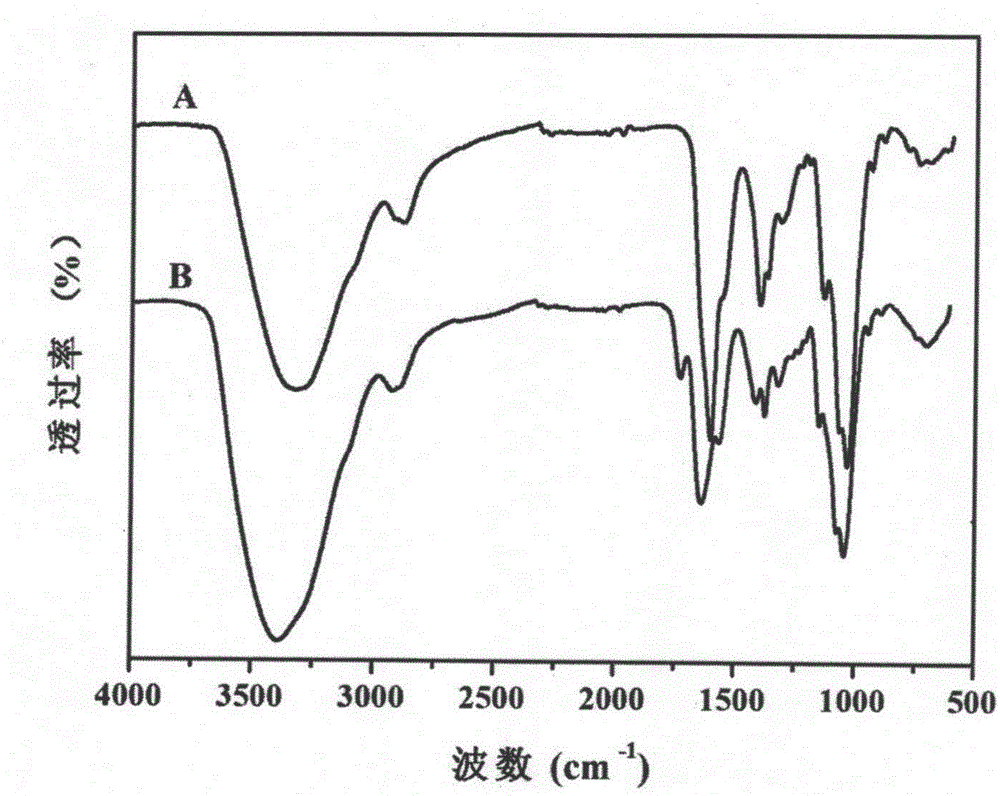

[0029] (1) Use sodium periodate to oxidize hyaluronic acid into formylated hyaluronic acid, obtain the oxidized solid after purification and freeze-drying, wherein the molar mass of sodium periodate and a structural unit in the hyaluronic acid molecular chain The ratio is 5:4;

[0030] (2) Dissolving the oxidized hyaluronic acid and carboxymethyl chitosan in step (1) respectively in phosphate buffered saline solution, the concentration of both solutions being 6 wt%. ;

[0031] (3) After the two solutions in step (2) are completely dissolved, respectively draw 0.5mL of the two polymer solutions and add them to the 24-well cell culture plate to quickly stir the two solutions evenly, and water can be found after standing for two minutes. The gel has transformed from a liquid to a solid state to form a pure hydrogel.

Embodiment 2

[0033] A preparation method of nanometer mesoporous silicon composite hydrogel with controlled release function:

[0034] (1) Using sodium periodate to oxidize hyaluronic acid into formylated hyaluronic acid, after purification and freeze-drying, the oxidized solid is obtained, wherein the molar mass ratio of sodium periodate to a unit of hyaluronic acid is 5: 4;

[0035] (2) the oxidized hyaluronic acid and carboxymethyl chitosan in the step (1) are dissolved in phosphate buffered saline respectively, and the concentration of both solutions is 6wt%;

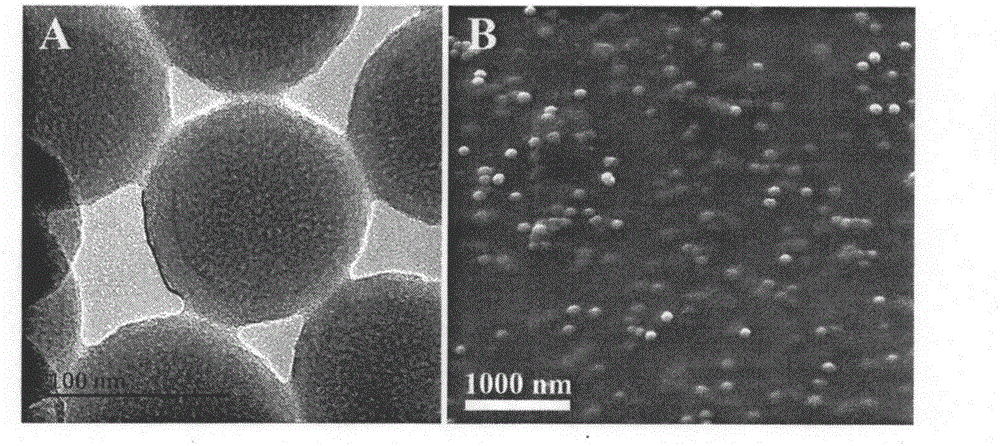

[0036] (3) Prepare mesoporous silicon nanoparticles, disperse them in deionized water at a concentration of 0.1%, and add the model drug FITC (accounting for one-tenth of the mass of nanoparticles) to the solution after the mesoporous silicon nanoparticles are uniformly dispersed Ultrasonic dispersion in medium, and stirring in the dark for 24 hours, so that FITC is loaded into the pores of mesoporous silicon nanoparticles, and...

Embodiment 3

[0039] A preparation method of nanometer mesoporous silicon composite hydrogel with controlled release function:

[0040] (1) Using sodium periodate to oxidize hyaluronic acid into formylated hyaluronic acid, after purification and freeze-drying, the oxidized solid is obtained, wherein the molar mass ratio of sodium periodate to a unit of hyaluronic acid is 5: 4;

[0041] (2) the oxidized hyaluronic acid and carboxymethyl chitosan in the step (1) are dissolved in phosphate buffered saline respectively, and the concentration of both solutions is 6wt%;

[0042](3) Prepare mesoporous silicon nanoparticles, disperse them in deionized water at a concentration of 0.1%, and add the model drug FITC (accounting for one-tenth of the mass of nanoparticles) to the solution after the mesoporous silicon nanoparticles are uniformly dispersed Ultrasonic dispersion in medium, and stirring in the dark for 24 hours, so that FITC is loaded into the pores of mesoporous silicon nanoparticles, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com