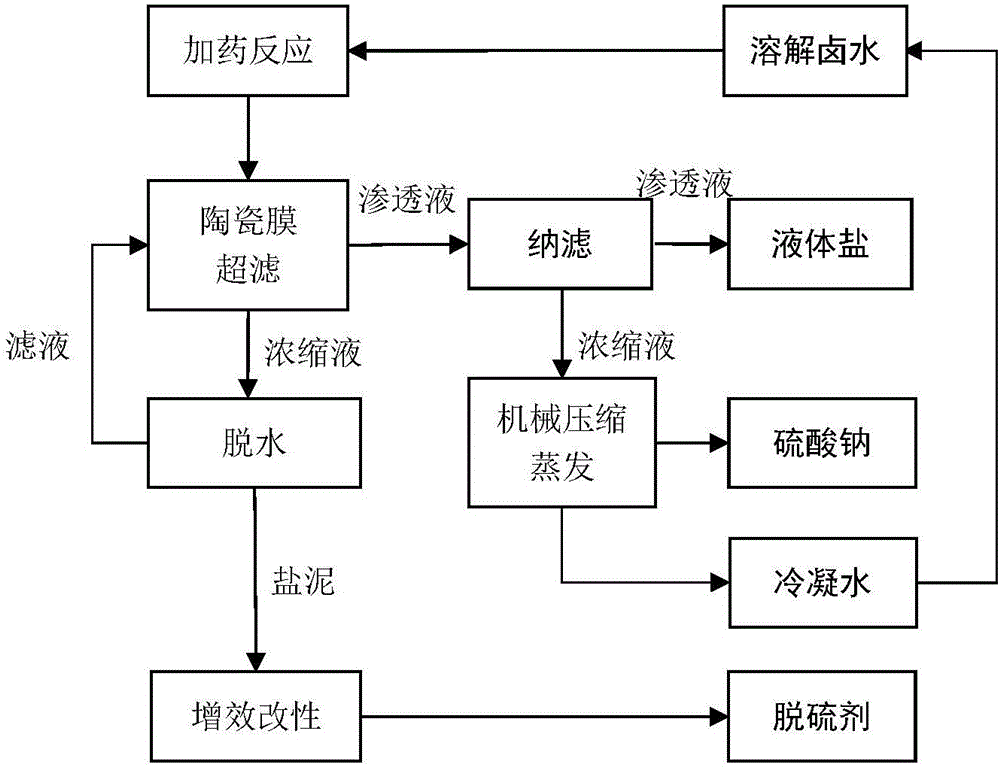

Double-membrane liquid salt refining zero-emission production technology

A production process and liquid salt technology, applied in chemical instruments and methods, alkali metal sulfite/sulfite, alkali metal chloride, etc., to achieve the effects of reducing energy consumption, improving production quality, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve mineral salt with water to obtain dissolved brine, pump the brine solution to the reaction tank, add 0.01% of the total mass of sodium carbonate, and at the same time add 0.01% of the total mass of nucleating agent calcium carbonate; after 0.2 hours of reaction, pump it into the ceramic membrane ultrafiltration unit, the operating pressure is 0.1MPa, and the membrane pore size is 1μm. The ceramic membrane ultrafiltration permeate enters the nanofiltration unit; the ceramic membrane ultrafiltration concentrate enters the vacuum filter for dehydration to obtain solid salt mud, the operating pressure is 80kPa (absolute pressure), and the separation material of the filter is a porous plate with a pore size of 0.1mm . The filtrate is returned to the ceramic membrane ultrafiltration unit.

[0024] Add citric acid with a mass ratio of 1% to the salt mud for reaction, and the reaction time is 20 minutes to prepare a desulfurizer.

[0025] The operating pressure of th...

Embodiment 2

[0028] Dissolve mineral salt with water to obtain dissolved brine, pump the brine solution to the reaction tank, add potassium carbonate with a total mass of 2% of the system, and add nucleating agent calcium sulfate with a total mass of 1% at the same time; pump it into a ceramic membrane ultrafiltration unit after reacting for 3 hours , the operating pressure is 0.3MPa, and the membrane pore size is 0.03μm. The ceramic membrane ultrafiltration permeate enters the nanofiltration unit; the ceramic membrane ultrafiltration concentrate enters the vacuum filter for dehydration to obtain solid salt mud. The operating pressure is 1kPa (absolute pressure). The hole diameter is 0.1mm. The filtrate is returned to the ceramic membrane ultrafiltration unit.

[0029] A mixture of adipic acid and metasilicate (1:1 molar ratio) was added to the salt mud for reaction with a mass ratio of 15%, and the reaction time was 120 minutes to prepare a desulfurizer.

[0030] The operating pressure ...

Embodiment 3

[0033] Dissolve mineral salt with water to obtain dissolved brine, pump the brine solution to the reaction tank, add 1.5% of the total mass of sodium hydroxide, and simultaneously add 0.5% of the total mass of nucleating agent calcium carbonate; after 1.5 hours of reaction, pump it into the ceramic membrane supernatant The filter unit has an operating pressure of 0.2 MPa and a membrane pore size of 0.2 μm. The ceramic membrane ultrafiltration permeate enters the nanofiltration unit; the ceramic membrane ultrafiltration concentrate enters the vacuum filter for dehydration to obtain solid salt mud. The operating pressure is 40kPa (absolute pressure). The separation material of the filter is a metal porous plate with a pore size of 0.2 mm. The filtrate is returned to the ceramic membrane ultrafiltration unit.

[0034] Add phthalic acid with a mass ratio of 10% to the salt mud for reaction, and the reaction time is 80 minutes to prepare a desulfurizer.

[0035] The operating pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com