Method for detoxicating chrome leaching residues through sintering technology

A technology for leaching slag and technology, which is applied in the detoxification field of chromium leaching slag, can solve the problems of large consumption of raw materials, high processing cost, and low detoxification efficiency, and achieve the effects of low production energy consumption, high detoxification efficiency, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

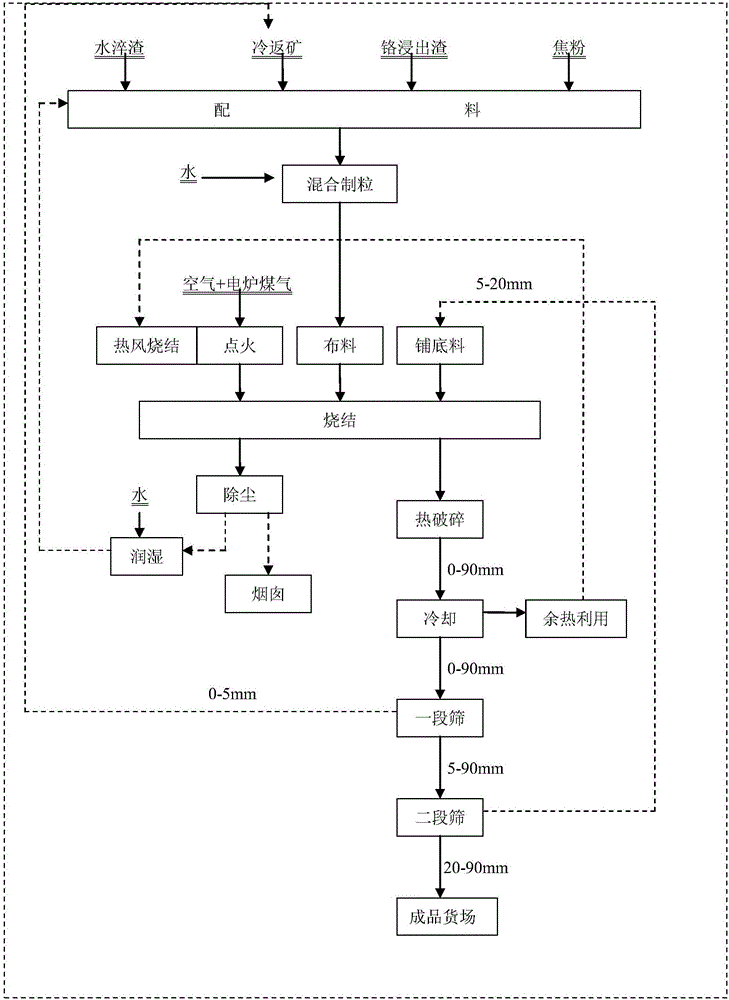

Method used

Image

Examples

Embodiment 1

[0050] 1. Screening of chromium leaching residue

[0051] The chromium slag (the industrial waste slag produced by calcium roasting to produce metal chromium) is screened, and the chromium slag whose granularity is selected is 50 orders-3mm;

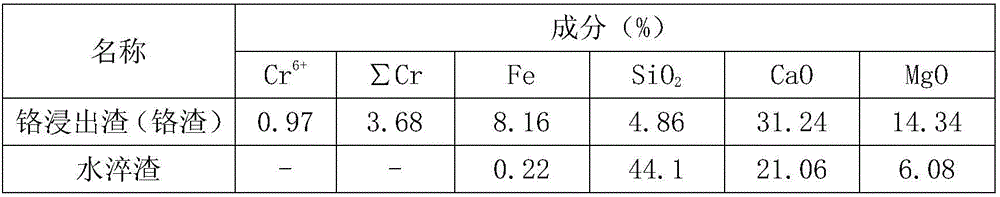

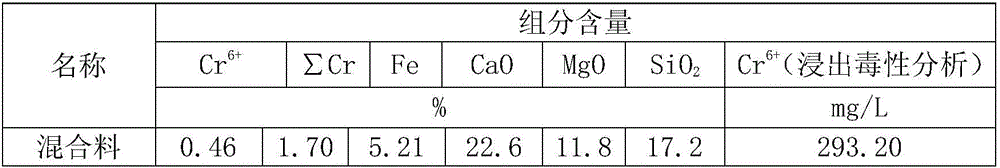

[0052] 2. Mix the ingredients evenly

[0053] Chromium slag (composition is shown in Table 1), water-quenched slag discarded during silicon-manganese alloy production (composition is shown in Table 1), and coke powder are batched according to the mass ratio of 80:20:15; after being fully mixed by a mixer, the mixture is obtained. Add water to make mixture particles with a particle size of 5mm-8mm, and control the water content of the particles to 7%;

[0054] 3. Cloth, ignition, sintering

[0055] Distribute the mixture particles evenly on the sintering trolley to ensure that the mixture particles are spread evenly and cover the sintering trolley. The thickness of the sintering material layer is controlled at 450mm, and the thickness o...

Embodiment 2

[0062] 1. Screening of chromium leaching residue

[0063] like figure 1 As shown, chromium slag (composition is as table 1) is screened, and choosing particle size is the chromium slag of 50 order-3mm;

[0064] 2. Mix the ingredients evenly

[0065] The chromium slag, the water-quenched slag discarded during the production of silicomanganese alloy (the composition is shown in Table 1), and the coke powder are mixed according to the mass ratio of 90:10:15; after being fully mixed by the mixer, the mixture is obtained, and the particle size is 5mm after adding water. -8mm mixture particles, and control the particle moisture to 6.5%;

[0066] 3. Cloth, ignition, sintering

[0067] Distribute the mixture particles evenly on the sintering trolley to ensure that the mixture particles are spread evenly and cover the sintering trolley. The thickness of the sintering material layer is controlled at 450mm, and the thickness of the bottom layer is 80mm; use air and electric furnace ga...

Embodiment 3

[0074] 1. Screening of chromium leaching residue

[0075] Sieve the chromium slag (with calcium roasting), and select the chromium slag whose particle size is 50 mesh-3mm;

[0076] 2. Mix the ingredients evenly

[0077] The water-quenched slag and coke powder discarded during the production of chromium slag and silicon-manganese alloy are mixed according to the mass ratio of 70:30:15; the mixture is obtained after being fully mixed by the mixer, and the mixture granules with a particle size of 5mm-8mm are made by adding water , and control the particle moisture to 6%;

[0078] 3. Cloth, ignition, sintering

[0079] Distribute the mixture particles evenly on the sintering trolley to ensure that the mixture particles are spread evenly and cover the sintering trolley. The thickness of the sintering material layer is controlled at 450mm, and the thickness of the bottom layer is 80mm; the ignition temperature is controlled at 1100°C-1200°C; sintering The negative pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com