Full-automatic anti-light decay laser processing equipment of solar cell sheet

A solar battery sheet and laser processing technology, which is applied in the direction of sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of unsatisfactory processing efficiency, unsuitable for high-efficiency production, complex process, etc., and achieve simple structure, high processing efficiency, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

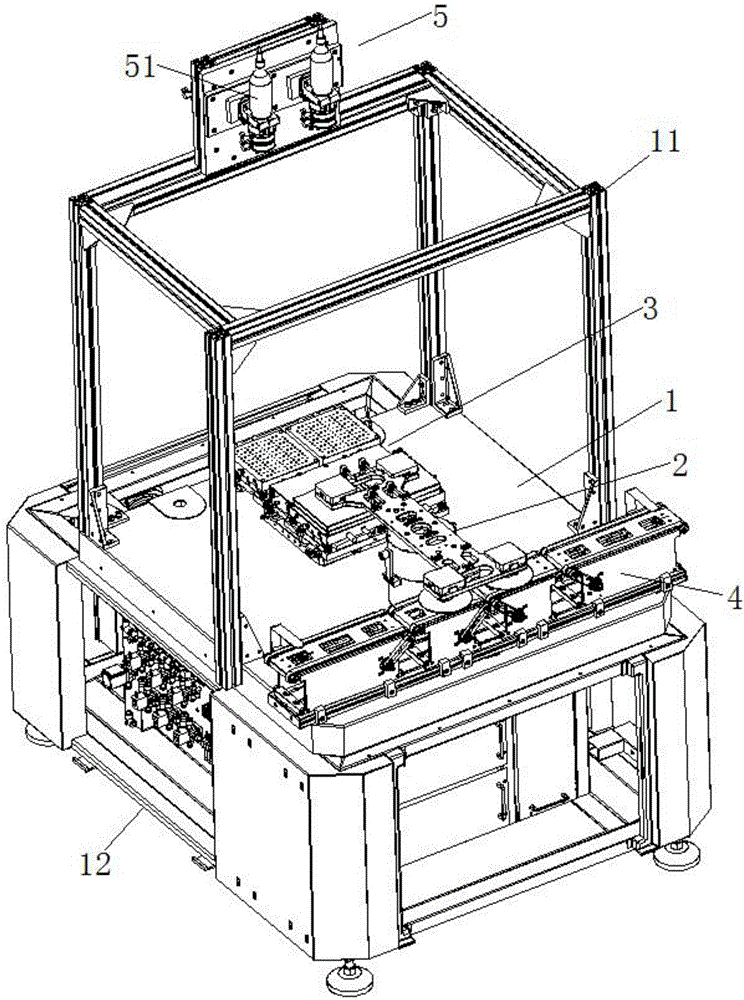

[0044] Example: such as figure 1 As shown, the fully automatic solar cell sheet anti-light attenuation laser processing equipment in this embodiment includes a processing table 1, a mechanical rotating arm assembly 2, a rotating temperature-controlled adsorption workbench 3, a cell transfer module 4 and a laser generator module Group 5;

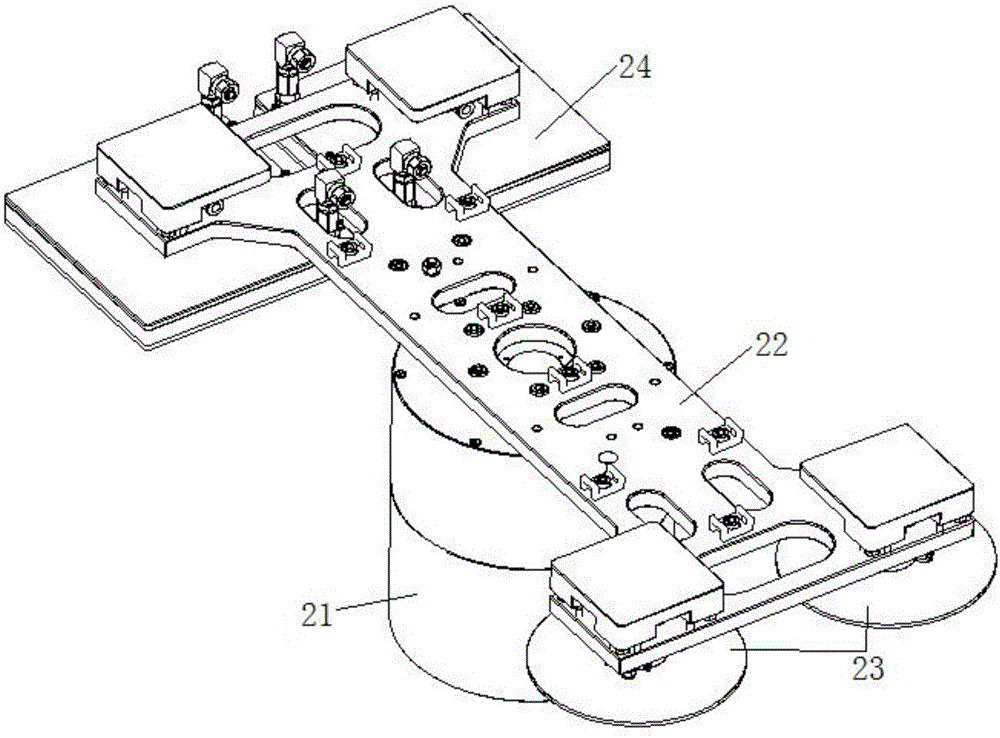

[0045] The mechanical rotating arm assembly 2, the rotating temperature-controlled adsorption workbench 3, and the cell transfer module 4 are installed on the processing table 1 respectively, and the above-mentioned rotating temperature-controlled adsorption workbench 3 and the cell transfer module 4 are distributed on the above-mentioned mechanical rotating Both sides of the arm assembly 2 can rotate horizontally on the above-mentioned processing table 1;

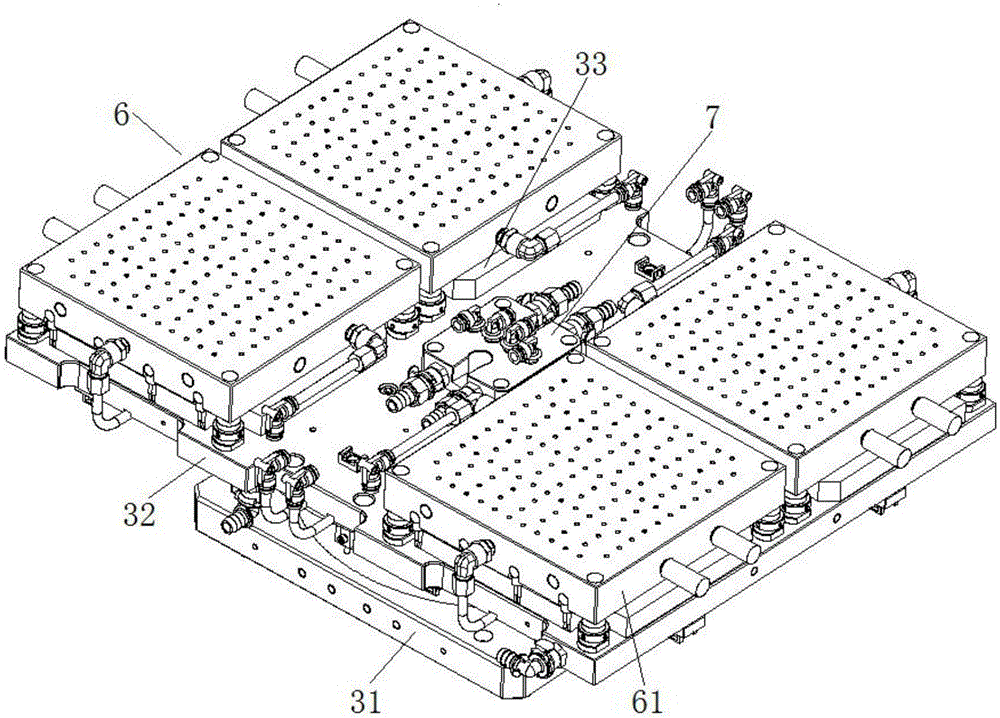

[0046] The upper end of the rotating temperature-controlled adsorption workbench 3 is provided with two sets of parallel and symmetrically distributed temperature-controlled sucker modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com