Cilostazol sustained-release capsule compound and preparation method thereof

A technology of cilostazol and sustained-release capsules, which is applied in the field of cilostazol sustained-release capsule compositions and its preparation, can solve problems such as difficulty in large-scale production, side effects of patients, and inconvenient dosage, and achieve product controllability Strong, easy to industrialize, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

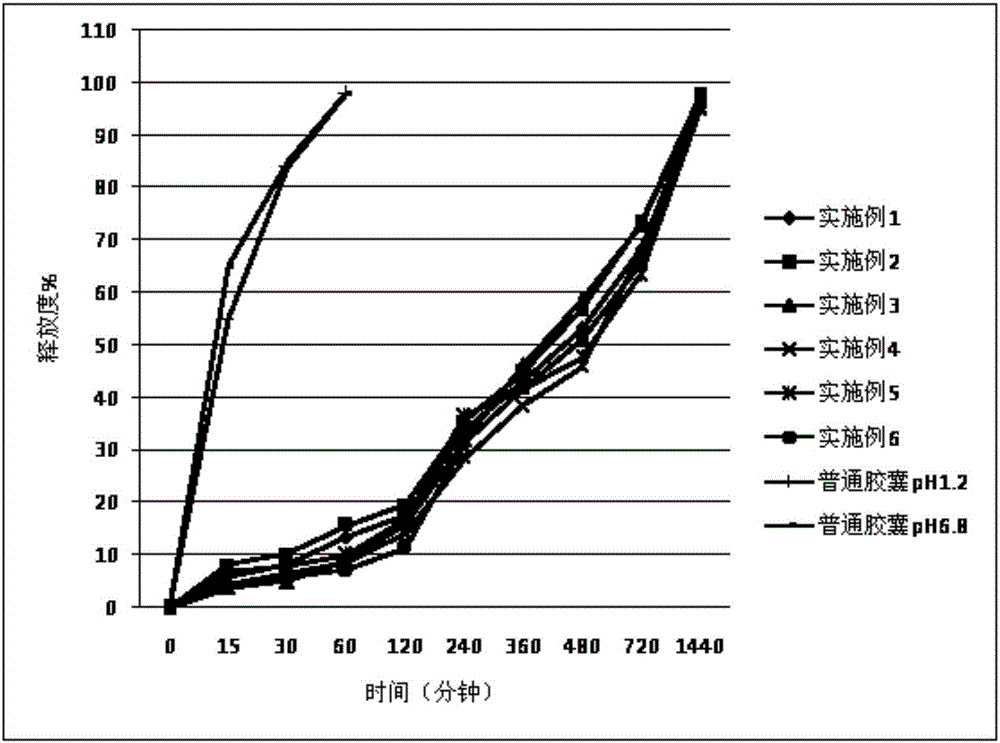

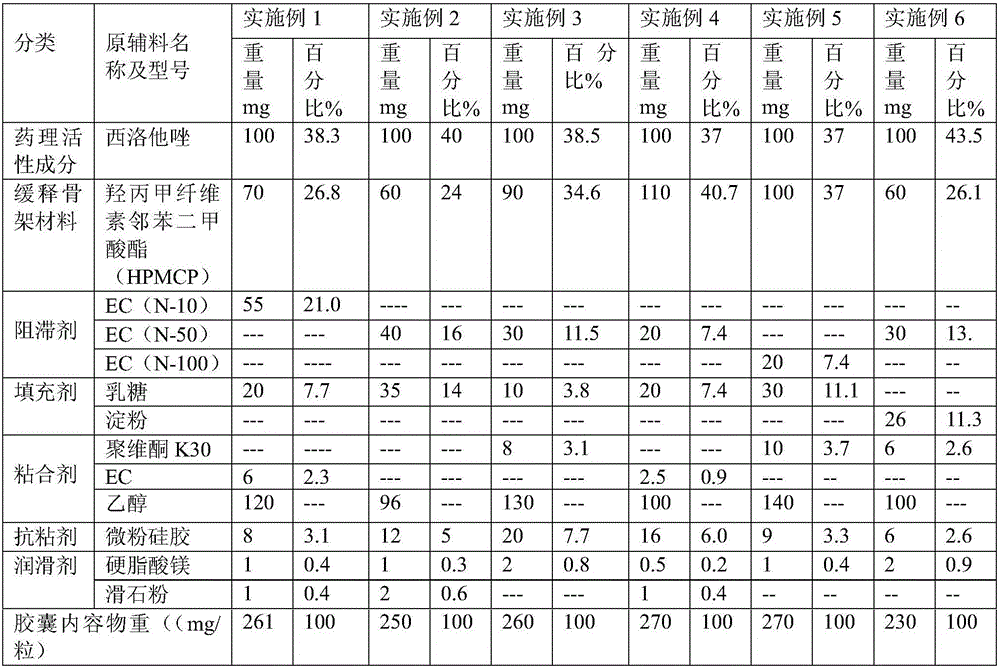

[0027] The cilostazol sustained-release capsules (specification: 100 mg / capsule) of Examples 1-6 are composed of the raw and auxiliary materials in the following weight ratios as shown in Table 1.

[0028] Table 1

[0029]

Embodiment 7-11、 comparative example 1

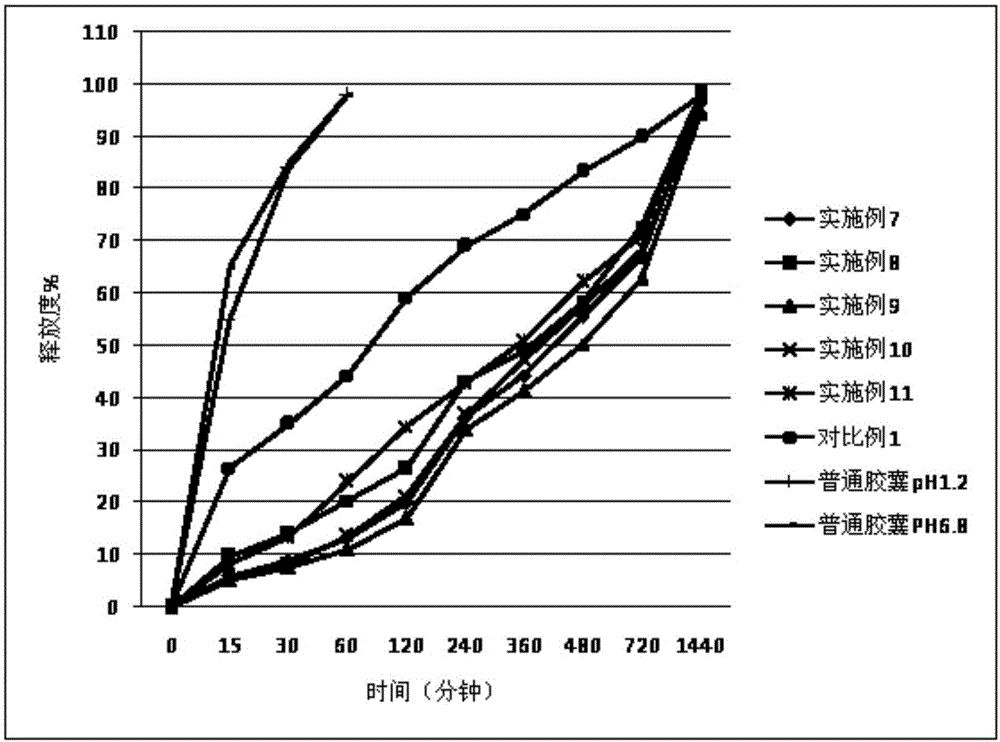

[0031] The cilostazol sustained-release capsules (specification: 200 mg / capsule) of Examples 7-11 and Comparative Example 1 are composed of the following raw and auxiliary materials in the weight ratio as shown in Table 2.

[0032] Table 2

[0033]

[0034]

Embodiment 12

[0036] The preparation method of the cilostazol sustained-release capsules of the present embodiment is as follows:

[0037] The cilostazol is micronized and passed through a 200-mesh sieve before mixing; the anti-sticking agent is passed through a 200-mesh sieve before mixing; the hypromellose phthalate sustained-release skeleton material and blocker Pass through a 80-mesh sieve before mixing; the filler pass through a 100-mesh sieve before mixing; and the lubricant pass through a 100-mesh sieve before mixing.

[0038] Mix the prescribed amount of cilostazol, hypromellose phthalate sustained-release matrix material, blocker, filler, and anti-sticking agent evenly; dissolve the adhesive with ethanol; put the evenly mixed Cilostazol, hypromellose phthalate sustained-release framework material, blocker, filler, anti-adhesive agent made of soft material, granulated twice with 16-24 mesh sieve; After drying at 55°C, sieve with 16-24 mesh, add lubricant and mix well for 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com