Preparing method of silver-containing anti-bacterial dressing

A technology of silver nitrate and ascorbic acid, which is applied in the field of medicine and health, can solve the problems of secondary trauma, poor water absorption, and easy adhesion of wounds, and achieve the effects of avoiding secondary trauma, simple preparation method, and fast wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

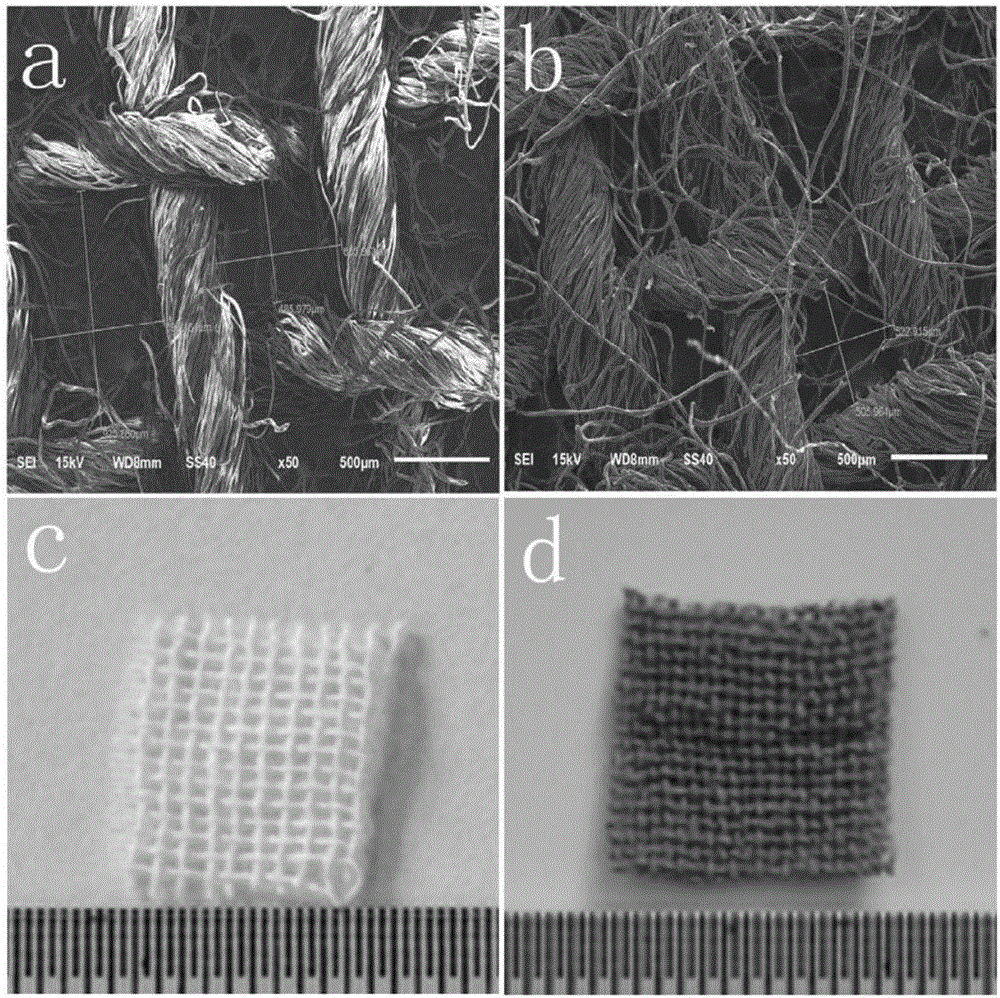

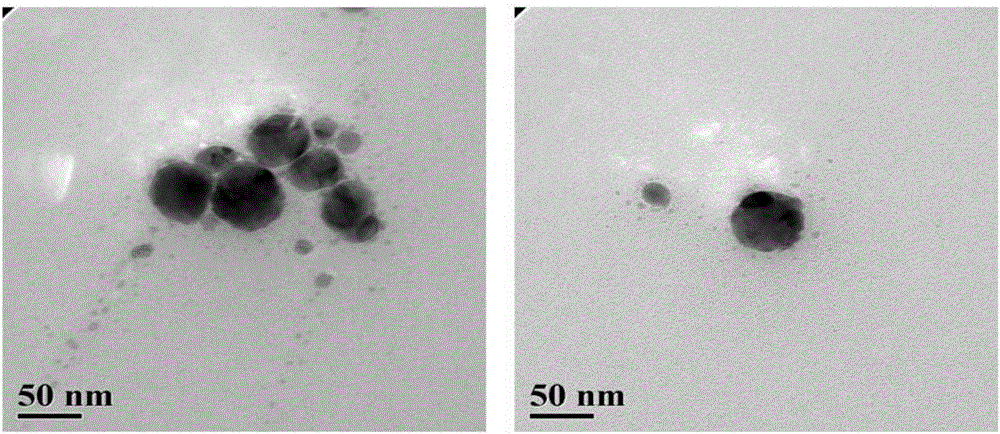

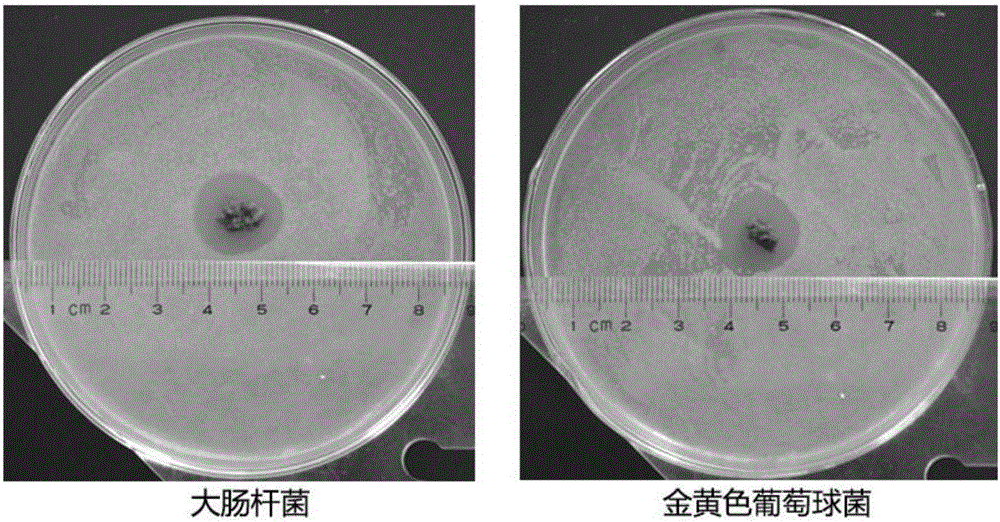

Image

Examples

Embodiment 1

[0028] A. Under the condition of 10°C, add the absorbent cotton gauze into the sodium hydroxide solution with a mass concentration of 20% to carry out the swelling reaction for 30 minutes, filter and dry after the reaction, and obtain the product A;

[0029] B. At 70°C, add product A to chloroacetic acid aqueous solution with a mass concentration of 15% to react for 15 minutes. Dry to obtain carboxymethyl cellulose cotton with carboxymethyl substitution degree of 0.47, the mass ratio of its absorbent cotton gauze to sodium hydroxide solution is 1:25, and the mass ratio of chloroacetic acid aqueous solution to product A is 5:1;

[0030] C, under the condition of 20 DEG C, polyvinylpyrrolidone is dissolved in ethanol to obtain a polyvinylpyrrolidone ethanol solution with a mass concentration of polyvinylpyrrolidone of 0.01%, and then add silver nitrate to obtain silver nitrate with a mass concentration of silver nitrate of 0.005% Ethanol solution, where ethanol is absolute ethan...

Embodiment 2

[0033] A. Under the condition of 15° C., the absorbent cotton gauze was added to a sodium hydroxide solution with a mass concentration of 22% for a swelling reaction for 35 minutes, and after the reaction, it was filtered and dried to obtain product A;

[0034] B. At 75°C, add product A to chloroacetic acid aqueous solution with a mass concentration of 20% and react for 18 minutes. Dry to obtain carboxymethyl cellulose cotton with carboxymethyl substitution degree of 0.45, the mass ratio of its absorbent cotton gauze to sodium hydroxide solution is 1:28, and the mass ratio of chloroacetic acid aqueous solution to product A is 10:3;

[0035] C, under the condition of 25 DEG C, polyvinylpyrrolidone is dissolved in ethanol, and the polyvinylpyrrolidone mass concentration obtained is 0.03% polyvinylpyrrolidone ethanol solution, and then silver nitrate is added to obtain silver nitrate ethanol with a silver nitrate mass concentration of 0.008% Solution, where the ethanol is absolut...

Embodiment 3

[0038] A. Under the condition of 20° C., the absorbent cotton gauze was added to a sodium hydroxide solution with a mass concentration of 24% to carry out a swelling reaction for 40 minutes, and filtered and dried after the reaction to obtain product A;

[0039] B. At 80°C, add product A to chloroacetic acid aqueous solution with a mass concentration of 25% and react for 20 minutes. After the reaction, use acetic acid with a mass concentration of 30% to adjust to neutrality, wash with ethanol and dry at 80°C , to obtain carboxymethyl cellulose cotton with carboxymethyl substitution degree of 0.5, the mass ratio of its absorbent cotton gauze to sodium hydroxide solution is 1:30, and the mass ratio of chloroacetic acid aqueous solution to product A is 2:1;

[0040] C, under the condition of 30 DEG C, dissolving polyvinylpyrrolidone in ethanol to obtain polyvinylpyrrolidone mass concentration is 0.05% polyvinylpyrrolidone ethanol solution, then add silver nitrate to obtain silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com