Three-dimensional scaffold applied to cell culture and preparation method thereof

A three-dimensional scaffold, cell culture technology, applied in the field of cell culture, can solve problems such as speeding up wound repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

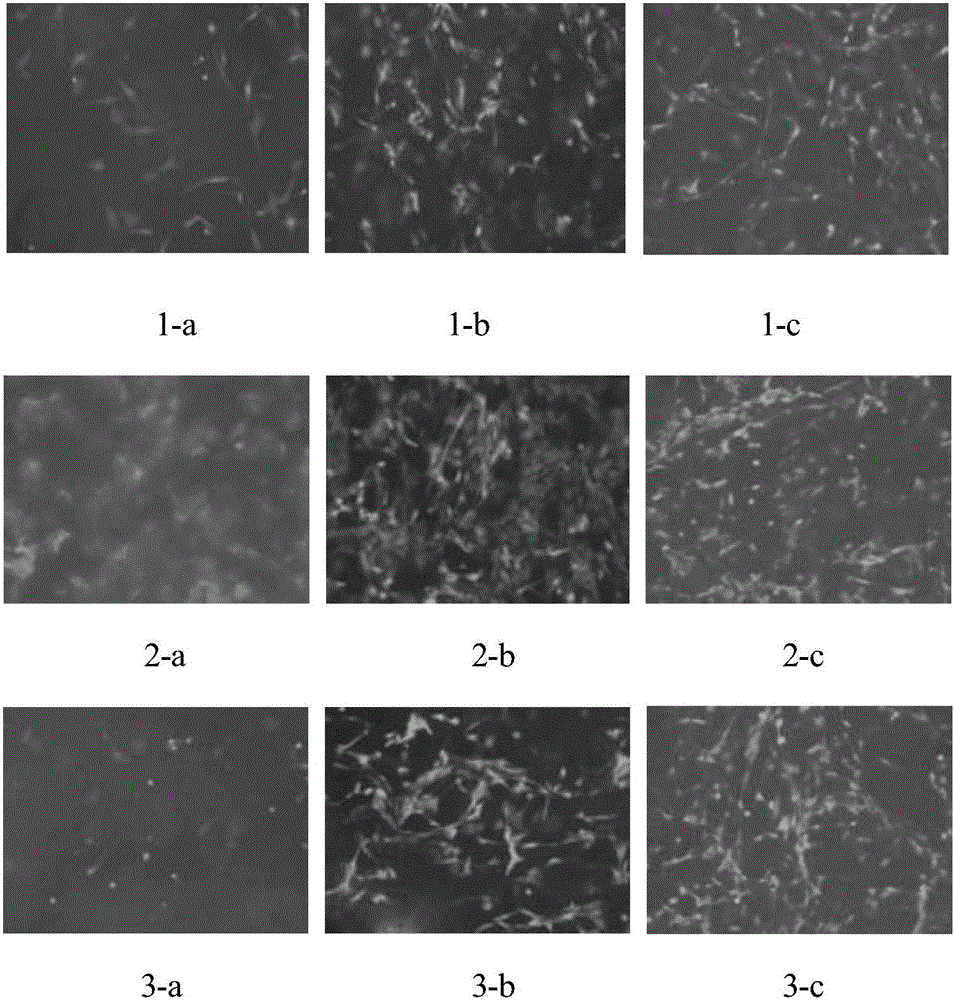

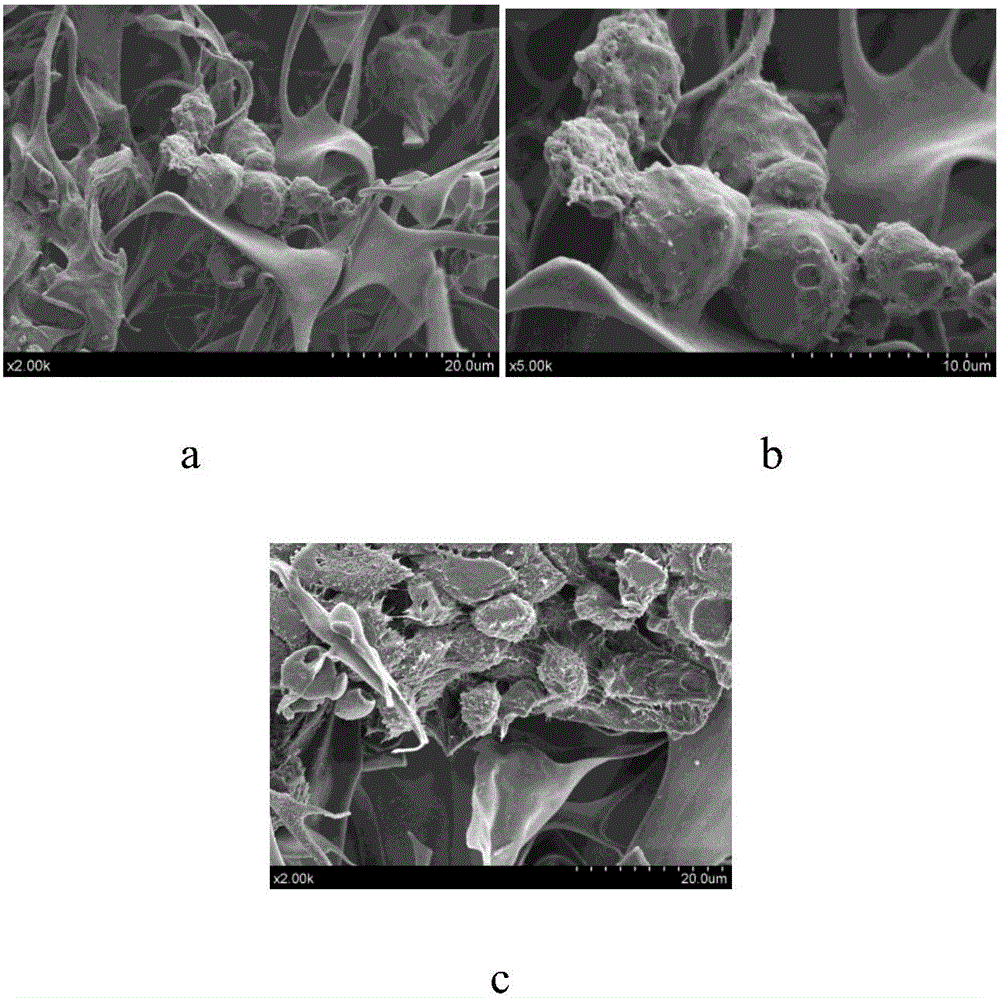

Examples

preparation example Construction

[0044]On the other hand, an embodiment of the present invention provides a method for preparing the three-dimensional scaffold as described above, including:

[0045] Step 1) preparing the acetic acid solution of the collagen-chitosan;

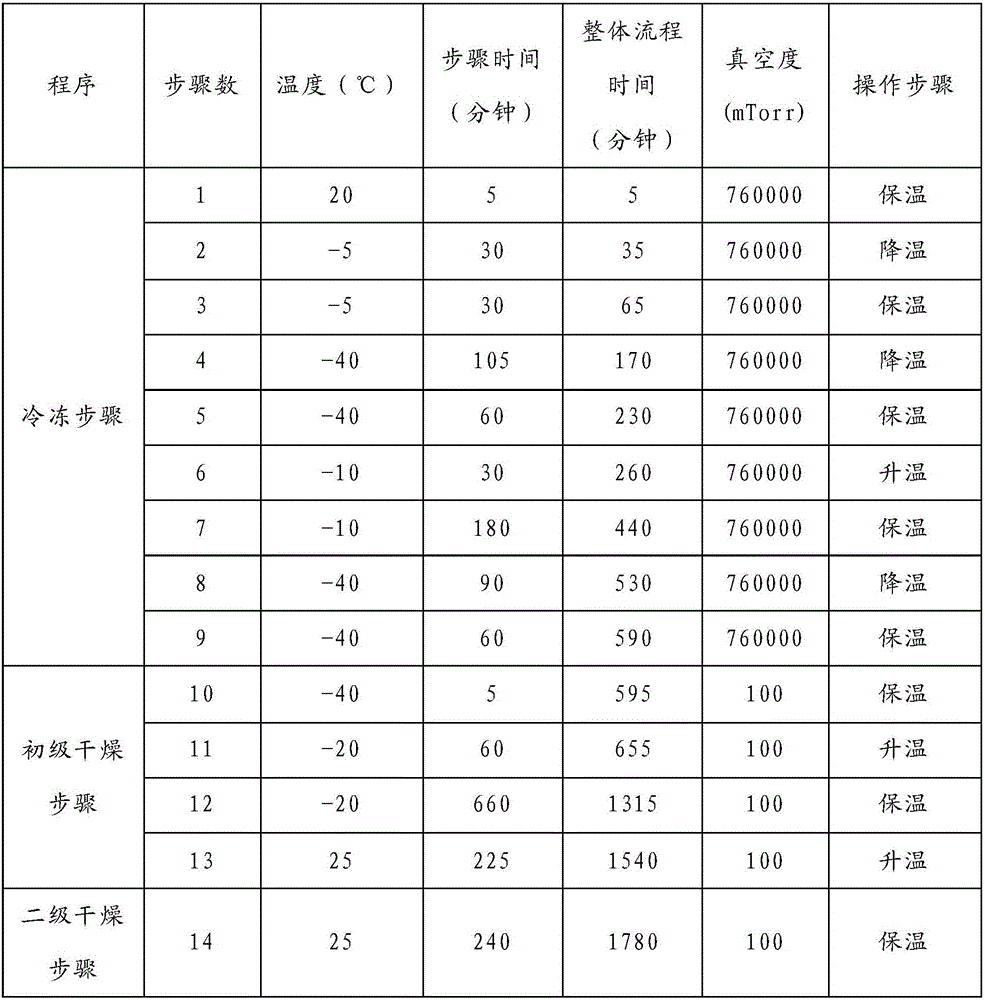

[0046] Step 2) degassing the acetic acid solution of collagen-chitosan and pouring it into a container, freeze-drying, and cutting into a preset shape to obtain a porous scaffold material;

[0047] Alternatively, a cell culture well plate with a plurality of holes is selected, wherein the cell culture well plate satisfies the following conditions: the cell culture well plate includes surrounding wells arranged on the edge and a central well surrounded by the surrounding wells at the center ;

[0048] The acetic acid solution of collagen-chitosan is defoamed and injected into the central hole to a preset height, and water is injected into the surrounding hole to a preset height, and then freeze-dried to obtain a porous scaffold material.

[0...

Embodiment 1

[0080] For convenience of description, the three-dimensional scaffold prepared in Example 1 is designated as A.

[0081] The specific preparation method is as follows:

[0082] 1) prepare the acetic acid solution of collagen-chitosan, wherein, the concentration of collagen is 0.1g / L, and the concentration of chitosan is 1g / L;

[0083] Specifically, first prepare an aqueous solution of acetic acid with a concentration of 0.1M / L, and perform sterile filtration; then mix chitosan with the aqueous solution of acetic acid in a certain ratio, and heat at 45° C. under stirring, Dissolving the chitosan in the aqueous solution of acetic acid to obtain an acetic acid solution of chitosan;

[0084] Then, add the collagen protein solution and water into the acetic acid solution of chitosan in a certain ratio, mix and stir evenly, and obtain the acetic acid solution of collagen-chitosan.

[0085] 2) The obtained collagen-chitosan acetic acid solution was injected into a plate with a diam...

Embodiment 2

[0091] For convenience of description, the three-dimensional scaffold prepared in Example 2 is designated as B.

[0092] The specific preparation method is as follows:

[0093] 1) prepare the acetic acid solution of collagen-chitosan, wherein, the concentration of collagen is 0.1g / L, and the concentration of chitosan is 25g / L;

[0094] Specifically, first prepare an aqueous solution of acetic acid with a concentration of 0.1M / L, and perform sterile filtration; then mix chitosan with the aqueous solution of acetic acid in a certain ratio, and heat at 60° C. under stirring, Dissolving the chitosan in the aqueous solution of acetic acid to obtain an acetic acid solution of chitosan;

[0095] Then, add the collagen protein solution and water into the acetic acid solution of chitosan in a certain ratio, mix and stir evenly, and obtain the acetic acid solution of collagen-chitosan.

[0096] 2) The obtained collagen-chitosan acetic acid solution is injected into 60 central wells of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com