Slurry-bed reactor catalyst filtering assembly

A slurry bed reactor and filter assembly technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problem of poor anti-pollution ability and durability of bag filters, affecting the economic benefits of enterprises, and maintenance High cost and other problems, to achieve the effect of easy back cleaning, stable shape and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described with reference to accompanying drawing:

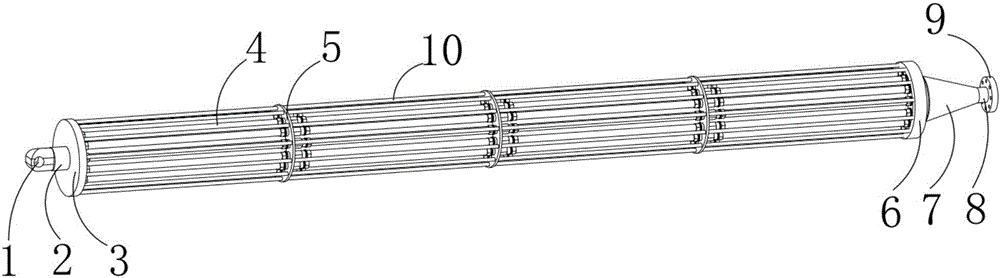

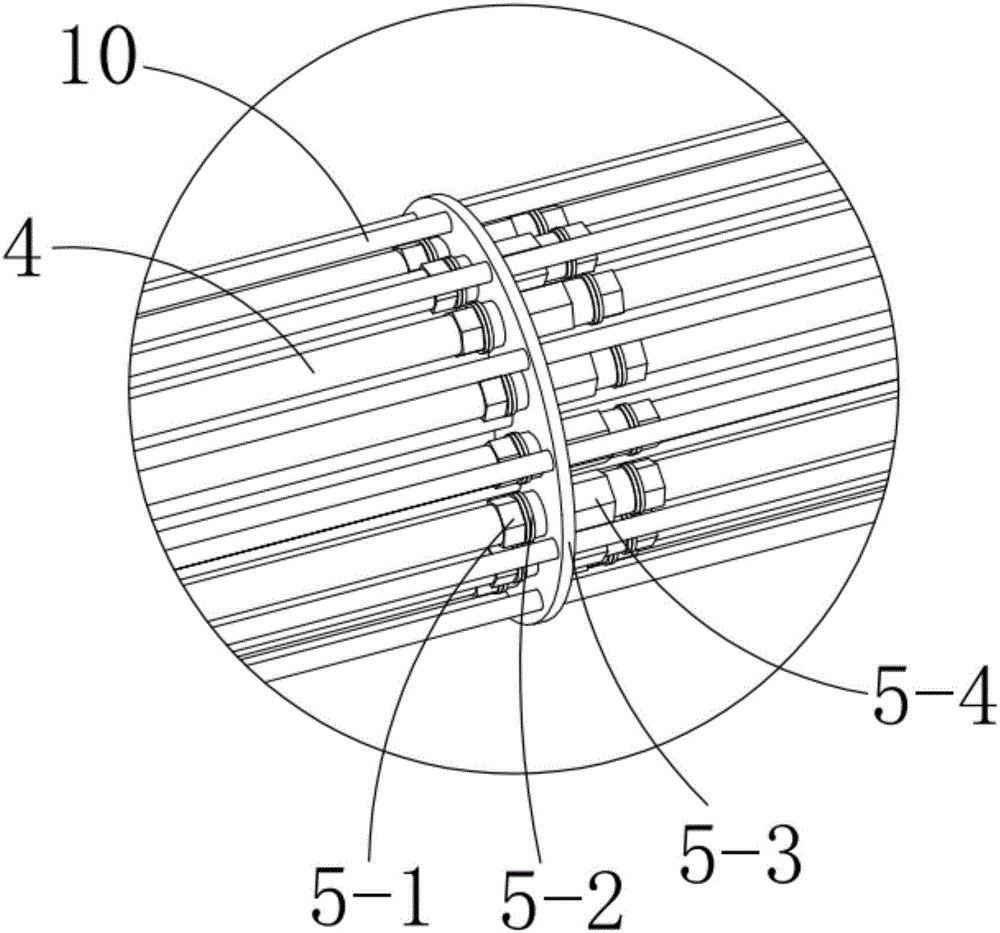

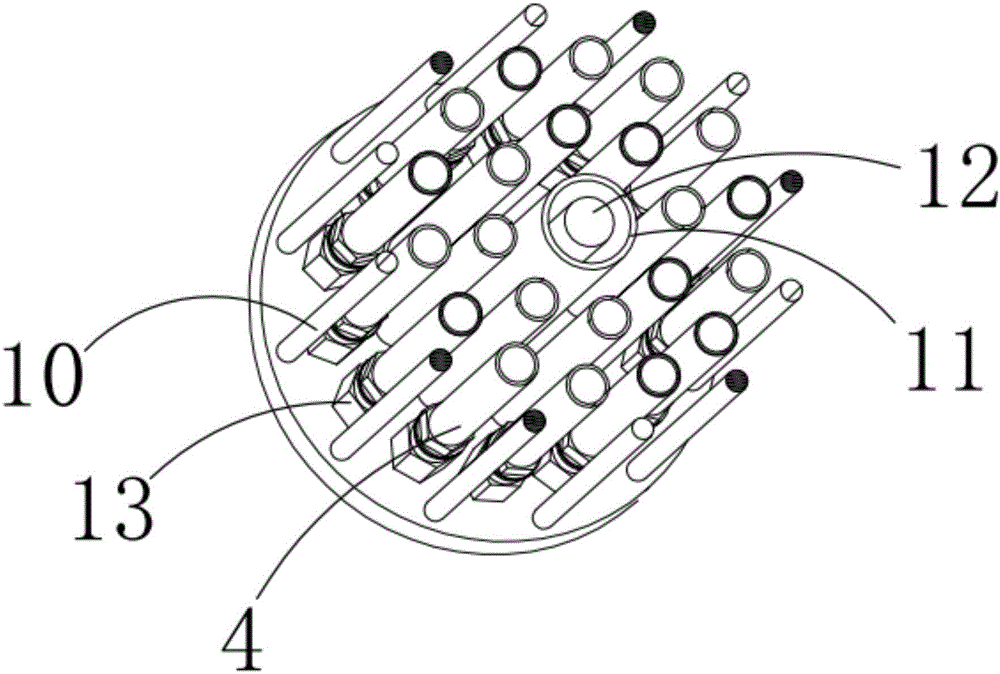

[0020] like figure 1 , figure 2 and image 3 Shown: a slurry bed reactor catalyst filter assembly, the filter assembly includes lifting lug 1, front flange 3, metal membrane tube assembly 4, membrane tube and flange connection 5, rear end flange 6, short-circuit Part 7 and short-circuit small flange 9. A central membrane tube 11 is arranged in the middle of the metal membrane tube assembly 4, and an exhaust pipeline 12 is arranged inside the central membrane tube 11. The fixed connection of the metal membrane tube assembly is assembled into four sections through the connection of the front flange 3, the membrane tube and the flange connection part 5, and the rear end flange 6. The metal membrane tubes on both sides of the membrane tube and the flange connection part 5 are connected. same membrane tube. Solid steel rods 10 are distributed around the periphery of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com