Production process and special mold for a hyperboloid honeycomb core board

A production process and honeycomb core technology, applied in the direction of layered products, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of high energy consumption, difficult to control pressure, poor contour, etc., and achieve simple preparation and operation methods, Effects of improving yield and quality, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

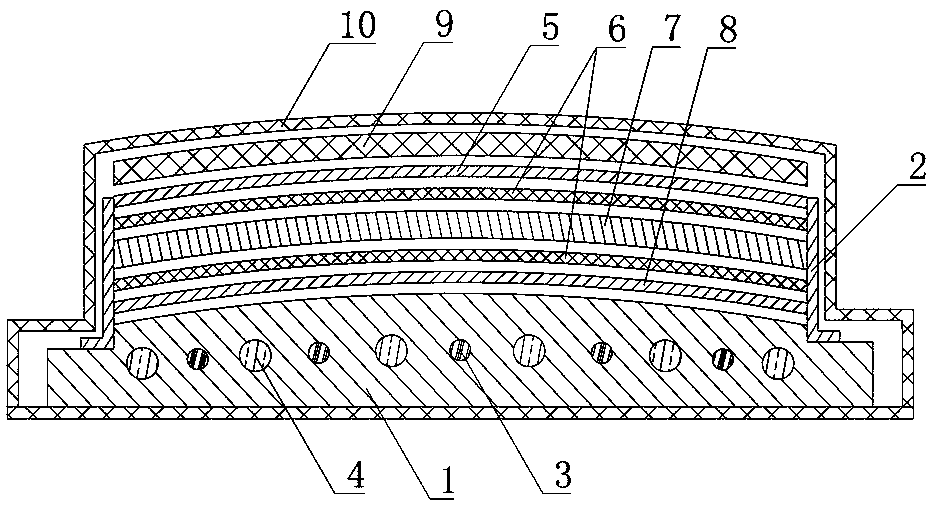

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0035] refer to figure 1 , the production technology of a kind of hyperboloid honeycomb core board of the present invention, comprises the following steps:

[0036] Step 1: According to the product requirements of the honeycomb core board, laser cutting is performed on the metal plate to obtain the face plate and bottom plate of the honeycomb core board;

[0037] Step 2: Surface treatment is carried out on the panel and base plate obtained in step 1. When the metal plate is an aluminum plate, the surface treatment process is phosphoric acid anodic oxidation treatment; when the metal plate is a carbon steel plate, the surface treatment process is sandblasting or sandpaper grinding;

[0038] Step 3: Apply primer on the adhesive surface of the panel and the bottom plate obtained in step 2, and the time interval between the step of applying the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com