Preparation method of battery grade lithium carbonate

A lithium carbonate, battery-grade technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of waste of gas raw materials, affecting gas utilization rate, only 7.6%, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

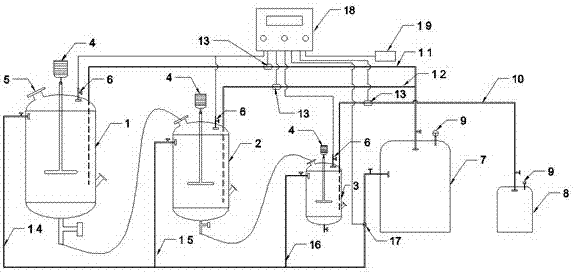

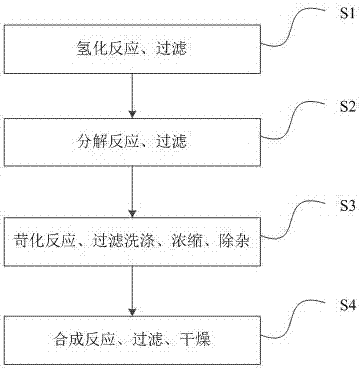

Method used

Image

Examples

Embodiment 1

[0074] The embodiment of the present invention provides the preparation method of battery grade lithium carbonate, and concrete steps are as follows:

[0075] Hydrogenation reaction: Weigh a certain quality of industrial-grade lithium carbonate and ordinary pure water to make a slurry. Turn on the stirring paddle that comes with the hydrogenation kettle. The interior of the hydrogenation kettle and the stirring paddle are made of titanium to prevent corrosion of the reaction equipment under strong alkali conditions. ~180, 170~175, 165~170r / min, the speed of the fixed stirring blade can effectively control the reaction rate, the hydrogenation reaction rate is the highest under this stirring speed, and the gas feeding device is used to add the collected CO 2 Gas and High Purity CO 2 Gas (purity above 99.99%), the gas velocity is controlled at 2~2.6, 1~1.5, 1.0~1.5m 3 / min, the temperature is controlled at 20 ~ 25 ℃, by installing in each CO 2 storage tank (to collect CO 2 st...

Embodiment 2

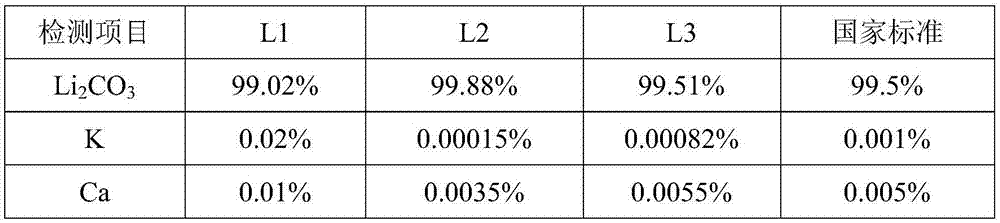

[0089] The preparation method of battery grade lithium carbonate: weigh 200kg industrial grade lithium carbonate, add to 1m 3 Add 600L of industrial water to the first-stage hydrogenation kettle, maintain the temperature at 25°C, control the speed of the stirring paddle at 180r / min, and add the collected CO with a gas feeding device. 2 Gas, the gas velocity is controlled at 2.4m 3 / min, after 1.8 hours of reaction, the collected CO 2 Gas consumption is 300m 3 (Under standard atmospheric pressure), the pH meter detects that the pH value in the reactor is 8.2, filters the solution, and adds 50 kg of lithium carbonate from the resulting filter residue to a 200L secondary hydrogenation kettle, and adds 100L of industrial water to it, and the temperature is maintained at 25 °C, the speed of the stirring blade is controlled at 175r / min, and the collected CO is added with a gas feeding device. 2 Gas, the gas velocity is controlled at 1.2m 3 / min, after 1 hour of reaction, the col...

Embodiment 3

[0099] The method for preparing battery-grade lithium carbonate by hydrogenating industrial-grade lithium carbonate: Weigh 200kg industrial-grade lithium carbonate and add to 1m 3 Add 600L of industrial water to the reaction kettle, keep the temperature at 25°C, control the speed of the stirring paddle at 180r / min, and control the gas velocity at 2.4m 3 / min, after 5 hours of reaction, high-purity CO 2 The amount of gas used is 700m 3 (Under standard atmospheric pressure) the pH meter detects that the pH value in the reaction kettle is 7.5, filters the solution, and the resulting filtrate is passed into the decomposition kettle, the temperature is controlled at 90°C, the rotating speed of the stirring paddle is 180r / min, and after 2.5 hours of decomposition Reaction, filtered while hot to obtain the filter residue, the filter residue and food-grade Ca(OH) 2 Equal masses are mixed, the mixed mass and ordinary pure water are prepared into a causticizing solution at a mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com