Cordierite ceramic synthesized from ceramic whiteware waste, and preparation method thereof

A technology for synthesizing cordierite and cordierite, which is applied in the field of automobile exhaust gas purification device materials or catalyst carrier materials, and refractory materials. It can solve the problems of difficult comprehensive treatment of solid waste and high cost of raw materials, achieve fine and uniform pore size distribution, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

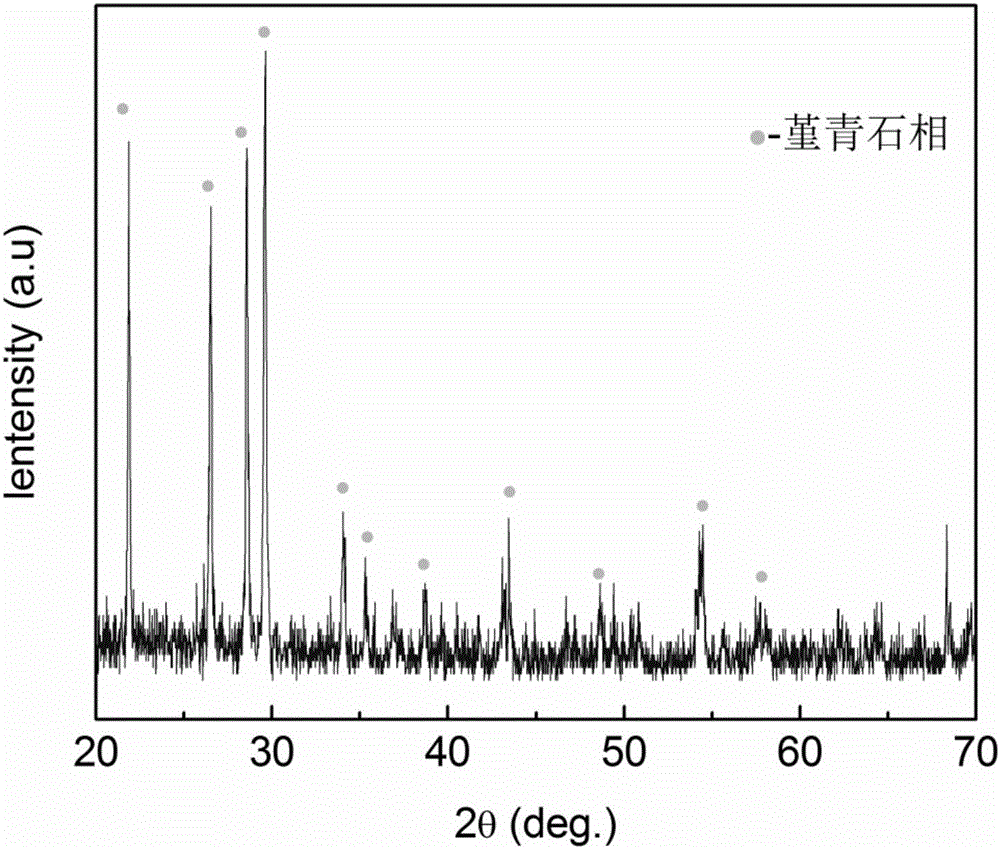

specific Embodiment 1

[0021] A method of synthesizing cordierite ceramics by using white porcelain waste. The raw materials include white porcelain waste, waste refractory materials, kaolin, and talc.

[0022] The above-mentioned preparation method for synthesizing cordierite ceramics by using white porcelain waste materials, the specific steps are as follows:

[0023] Step 1, according to the composition of the raw material formula, the raw material is wet-milled in a ball mill for 0.5 hours, the grinding medium is water, and the raw material: ball: water = 1:1.5:0.8;

[0024] Step 2, the ground slurry is filtered and dehydrated, put into a drying oven at 105°C for 12 hours, crushed and passed through a 100-mesh sieve;

[0025] Step 3, mixing the powder with a binder of 5% polyvinyl alcohol aqueous solution, molding under a pressure of 14MPa, and putting the molding blank into a drying oven at 105°C for 12 hours;

[0026] Step 4, the dry compact is placed in a kiln and fired at a high temperature...

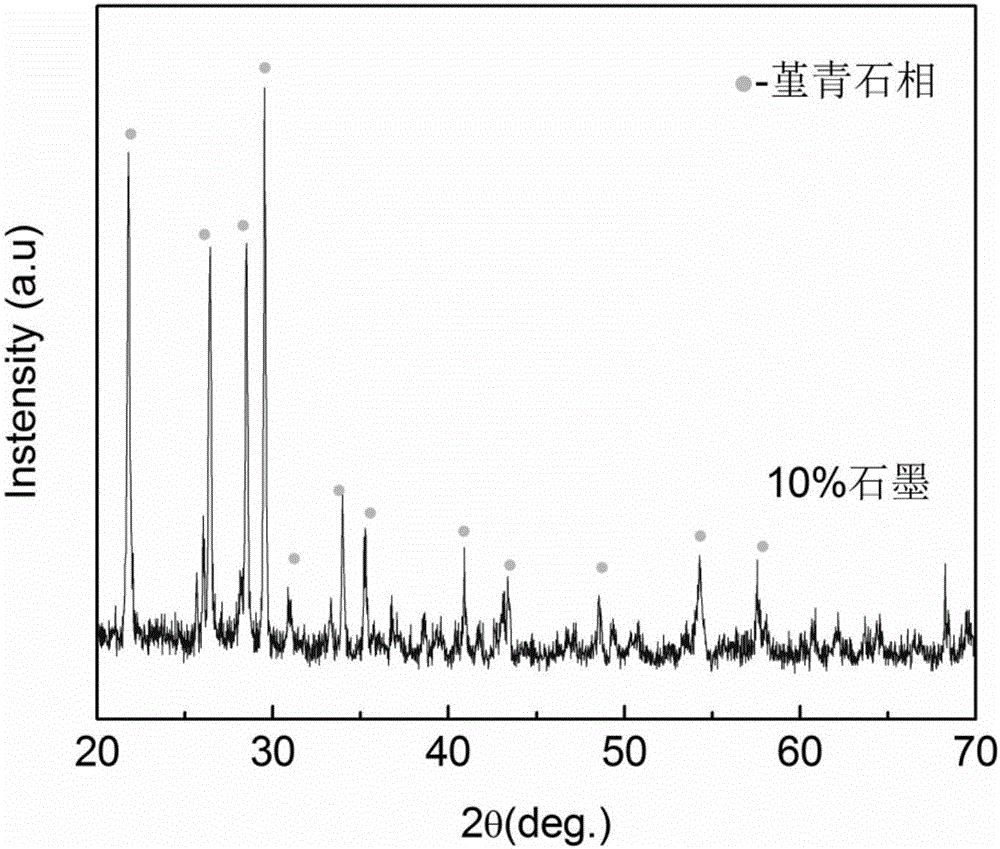

specific Embodiment 2

[0032] A method of synthesizing cordierite ceramics by using white porcelain waste, the raw materials include white porcelain waste 21, waste refractory material 22, kaolin 30, calcined talc 27, and pore-forming agent 10;

[0033] The pore-forming agent in this embodiment is graphite, and in addition, the pore-forming agent can be selected from materials that can be thermally decomposed such as starch and polymer microspheres;

[0034] The above-mentioned preparation method for synthesizing cordierite ceramics by using white porcelain waste materials, the specific steps are as follows:

[0035] Step 1, according to the composition of the raw material formula, the raw material is wet-milled in a ball mill for 0.5 hours, the grinding medium is water, and the raw material: ball: water = 1:1.5:0.8;

[0036] Step 2, the ground slurry is filtered and dehydrated, put into a drying oven at 105°C for 12 hours, crushed and passed through a 100-mesh sieve;

[0037] Step 3, the powder is...

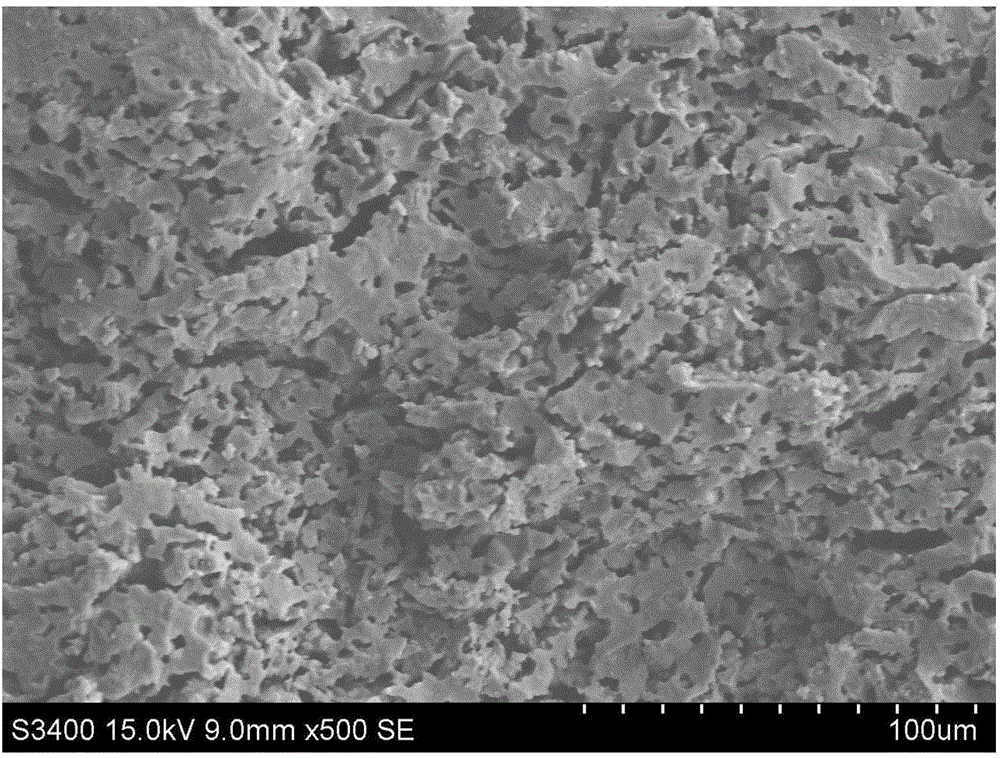

specific Embodiment 3

[0041] A method of synthesizing cordierite ceramics by using white porcelain waste. The raw materials include white porcelain waste 30 , waste refractory material 20 , kaolin 29 , and calcined talc 21 .

[0042] The above-mentioned preparation method for synthesizing cordierite ceramics by using white porcelain waste materials, the specific steps are as follows:

[0043] Step 1, according to the raw material formula composition batching, the raw material composition is prepared according to the following weight ratio;

[0044] Step 2, the raw material is wet-milled in a ball mill for 0.5 hour, the grinding medium is water, raw material: ball: water = 1:1.5:0.8;

[0045] Step 3: Select a polymer sponge foam suitable for porosity, and place it in the cavity of a stainless steel cuboid mold. Pour the ground slurry into the mold cavity with a built-in polymer sponge foam for impregnation. In order to ensure that the slurry fully fills the pores , in order to ensure that the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com