Method for preparation of sulfonate radical-functionalized large-specific surface area macroporous resin

A macroporous resin and resin technology, applied in the field of physical or chemical materials, can solve problems such as lack of pore structure, complicated steps, and pore size limitation, and achieve the effects of low cost, simple preparation method, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The raw material resin selected in the following examples is the specific surface area of XAD-4 macroporous resin is 1000m 2 / g, the average pore size is about 15nm, and the average particle size is 640μm.

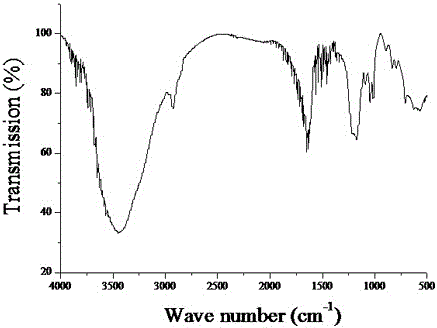

[0018] The preparation method of macroporous resin comprises the following steps: a. disperse the purchased XAD-4 macroporous resin in dichloromethane and fully swell; b. add chlorosulfonic acid as sulfonating reagent in reaction system, macroporous resin and chlorine The mass ratio of sulfonic acid is controlled at 1 / 5-1 / 30, and the sulfonation time is adjusted between 12-36 hours; c. Disperse the sulfonated product in a large amount of water, filter it with suction, wash it, and dry it. obtaining a sulfonate-functionalized macroporous resin material; d. using the prepared sulfonate-functionalized macroporous resin to catalyze reactions such as esterification of acetic acid and cyclohexanol, condensation of benzaldehyde and ethylene glycol, and the like.

[0019...

Embodiment 2

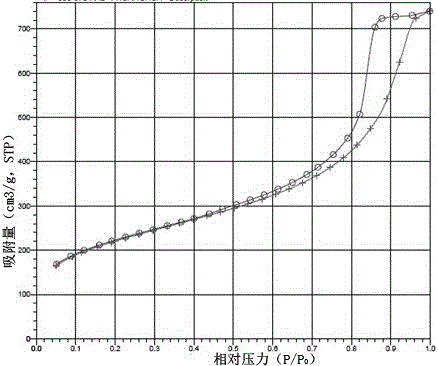

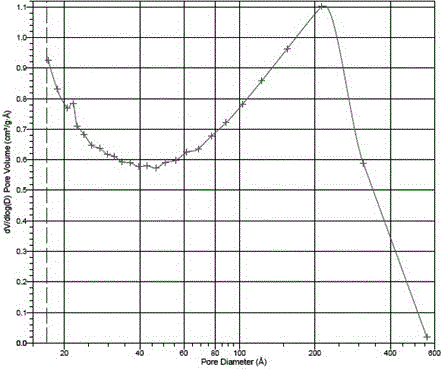

[0025] Take 1.0 g of XAD-4 macroporous resin and disperse it in 15 g of dichloromethane to fully swell for 1 hour, then add 5 g of chlorosulfonic acid, sulfonate at 0°C for 12 hours, then disperse the product in a large amount of deionized water, and filter with suction , washed to neutral, and dried to obtain the product with a specific surface area of 800m 2 / g, the pore volume reaches 1.13cm 3 / g, the pore diameter is 25.2 nanometers, and the acid center content is 1.2mmol / g.

Embodiment 3

[0027] Disperse 1.0 g of XAD-4 macroporous resin in 30 g of dichloromethane and swell fully for 1 hour, then add 15 g of chlorosulfonic acid, sulfonate at 8°C for 24 hours, then disperse the product in a large amount of deionized water, and filter with suction , washed to neutral, dried to obtain the specific surface area of the product product is 710m 2 / g, the pore volume reaches 1.0cm 3 / g, the pore diameter is 20.2 nanometers, and the acid center content is 2.8mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com