Preparation method of antibacterial nano latex paint for interior walls

A kind of latex paint and nanotechnology, applied in the field of coatings, can solve problems such as long-term humid weather, mildew on the inner wall, and bacterial growth on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

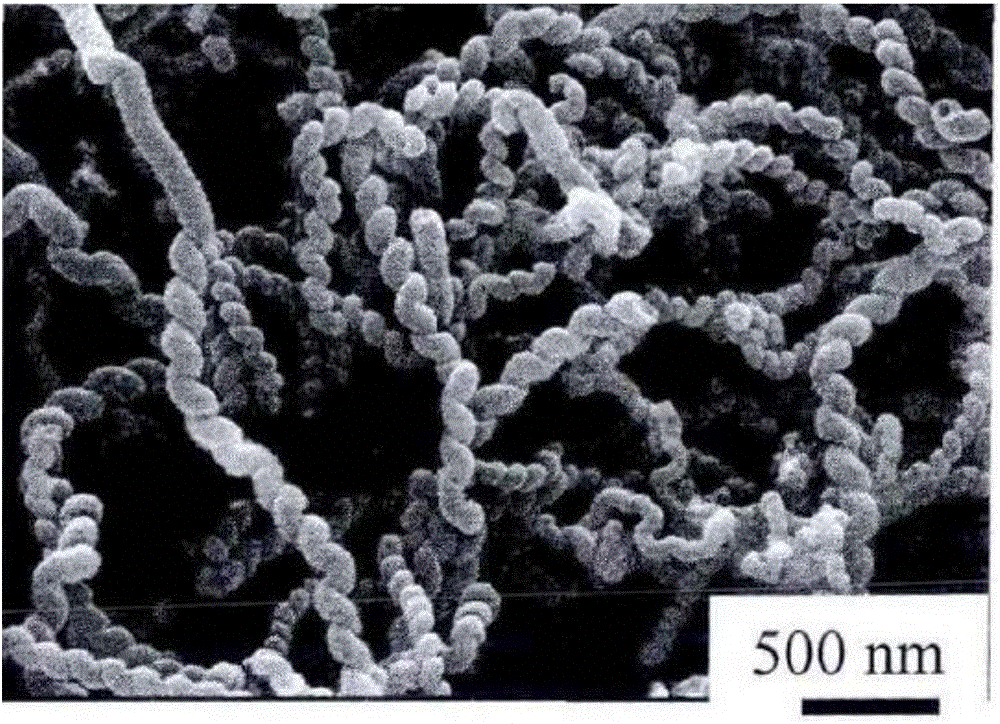

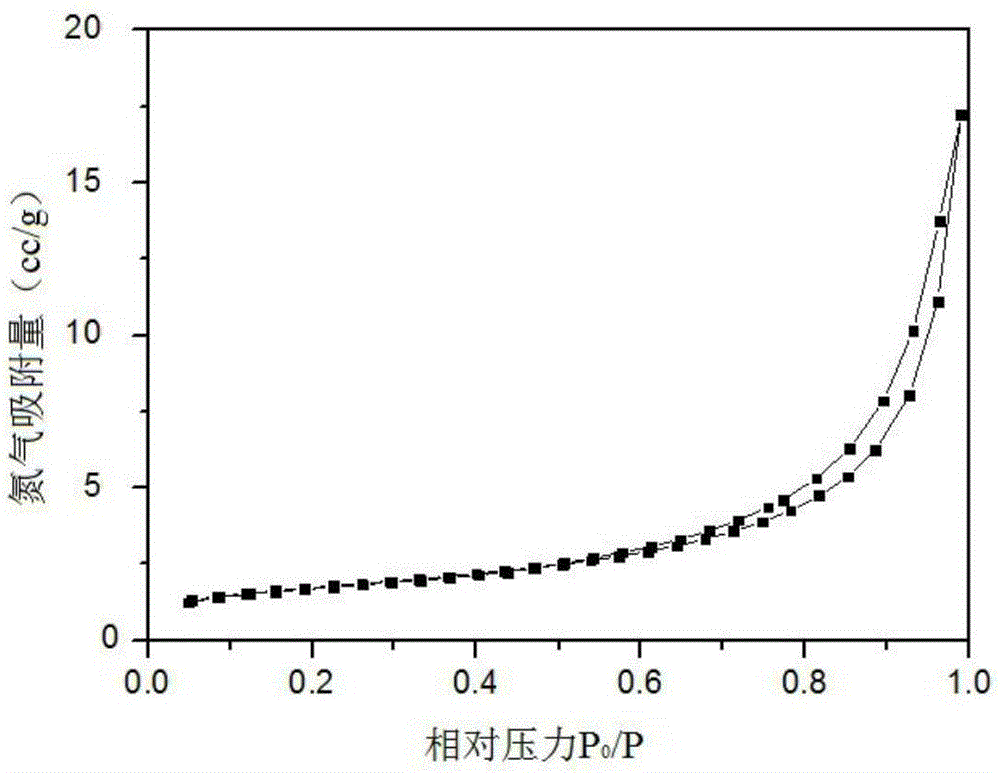

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of antibacterial interior wall nano-emulsion paint,

[0028] Step 1, solution A: Dissolve 8 parts of tetrabutyl titanate in a mixed solution of 5 parts of absolute ethanol and 5 parts of acetic acid, and fully stir for 20 minutes;

[0029] Solution B: Dissolve 2 parts of acetylacetone and 5 parts of absolute ethanol and mix with 5 parts of anhydrous acetic acid under stirring conditions, add 2.4 parts of mineral oil and 0.1 part of silver nitrate, mix well, and fully stir for 12 hours;

[0030] Step 2, mix A solution and B solution according to the ratio of 1:1, and fully stir for 12 hours to obtain a precursor colloid solution for preparing silver / titanium dioxide nanotubes;

[0031] Step 3, put the precursor solution prepared in step 2 into a spinneret with an inner diameter of 1 mm, the receiving device is grounded and rotated directly as a 100 mm aluminum roller, the receiving distance is 18 cm, the spinning voltage is 15 k...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of antibacterial interior wall nano-emulsion paint,

[0037] Step 1, solution A: dissolve 10 parts of tetrabutyl titanate in a mixed solution of 10 parts of absolute ethanol and 8 parts of acetic acid, and fully stir for 12 hours;

[0038] Solution B: Dissolve 6 parts of acetylacetone and 10 parts of absolute ethanol and mix with 7 parts of anhydrous acetic acid under stirring conditions, add 2.4 parts of mineral oil and 0.1 part of silver nitrate, mix well, and fully stir for 12 hours;

[0039] Step 2, mix A solution and B solution according to the ratio of 1:1, and fully stir for 12 hours to obtain a precursor colloid solution for preparing silver / titanium dioxide nanotubes;

[0040] Step 3, put the precursor solution prepared in step 2 into a spinneret with an inner diameter of 1.2mm, the receiving device is grounded and rotated directly as a 100mm aluminum roller, the receiving distance is 20cm, the spinning voltage is 20kV...

Embodiment 3

[0045] Embodiment 3: a kind of preparation method of antibacterial interior wall nano-emulsion paint,

[0046] Step 1, solution A: Dissolve 10 parts of tetrabutyl titanate in a mixed solution of 7.5 parts of absolute ethanol and 6.5 parts of acetic acid, and fully stir for 12 hours;

[0047] Solution B: Dissolve 4 parts of acetylacetone and 7.5 parts of absolute ethanol and mix with 6 parts of anhydrous acetic acid under stirring conditions, add 4.44 parts of mineral oil and 0.5 parts of silver nitrate, mix well, and fully stir for 12 hours;

[0048] Step 2, mix A solution and B solution according to the ratio of 1:1, and fully stir for 12 hours to obtain a precursor colloid solution for preparing silver / titanium dioxide nanotubes;

[0049] Step 3, put the precursor solution prepared in step 2 into a spinneret with an inner diameter of 1.1mm, the receiving device is grounded and rotated directly as a 100mm aluminum roller, the receiving distance is 19cm, the spinning voltage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com