Super-hydrophobic anticorrosive coating used for power transmission and transformation devices, and preparation method thereof

A technology for anti-corrosion coatings and power transmission and transformation equipment, applied in anti-corrosion coatings, radiation-absorbing coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor superhydrophobic properties of coatings, and achieve excellent corrosion resistance and high hydrophobicity The effect of excellent performance and water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A superhydrophobic anti-corrosion coating for power transmission and transformation equipment, comprising the following raw materials in parts by weight: 10 parts of modified nano-zirconia, 16 parts of modified nano-silica, 20 parts of polyurethane resin, 7 parts of curing agent, coupling 2 parts of agent, 0.5 parts of leveling agent, 1.5 parts of defoamer, 0.5 parts of dispersant, 0.6 parts of drier, 0.3 parts of antioxidant, 0.6 parts of ultraviolet absorber and 50 parts of solvent, wherein the polyurethane resin is acrylic polyurethane resin , the curing agent is cyclohexanone peroxide, the coupling agent is isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, the leveling agent is polydimethylsiloxane, and the defoaming agent is The agent is Dudao 5050, the dispersant is triethylhexyl phosphoric acid, the drier is dibutyltin dilaurate, the antioxidant is antioxidant 1010, the solvent is isopropanol, and the ultraviolet absorber is ultraviolet absorber...

Embodiment 2

[0043] A superhydrophobic anti-corrosion coating for power transmission and transformation equipment, comprising the following raw materials in parts by weight: 18 parts of modified nano-zirconia, 6 parts of modified nano-silica, 40 parts of polyurethane resin, 3 parts of curing agent, coupling 10 parts of agent, 1 part of leveling agent, 0.5 parts of defoamer, 1 part of dispersant, 0.2 parts of drier, 1.2 parts of antioxidant, 0.2 parts of ultraviolet absorber and 30 parts of solvent, wherein the polyurethane resin is alkyd polyurethane Resin, curing agent is polythiol curing agent POLYTHIOL3800, coupling agent is monoalkoxy unsaturated fatty acid titanate, leveling agent is polyether polyester modified organosiloxane, defoaming agent is BYK-057, The dispersant is sodium lauryl sulfate, the drier is dibutyltin dilaurate, the antioxidant is DLTP, the solvent is butyl acetate, and the ultraviolet absorber is ultraviolet absorber UV-0.

[0044] The preparation method of the modi...

Embodiment 3

[0049] A superhydrophobic anti-corrosion coating for power transmission and transformation equipment, comprising the following raw materials in parts by weight: 14 parts of modified nano-zirconia, 11 parts of modified nano-silica, 30 parts of polyurethane resin, 5 parts of curing agent, coupling 6 parts of agent, 0.75 parts of leveling agent, 1 part of defoamer, 0.75 parts of dispersant, 0.4 parts of drier, 0.75 parts of antioxidant, 0.4 parts of ultraviolet absorber and 40 parts of solvent, wherein the polyurethane resin is polyester polyurethane Resin, the curing agent is N3390, the coupling agent is isopropyl dioleate (dioctyl phosphate acyloxy) titanate, the leveling agent is polydimethylsiloxane, and the defoamer is DF -189, the dispersant is polyacrylamide, the drier is dibutyltin dilaurate, the antioxidant is antioxidant 168, the solvent is N,N-dimethylformamide, and the ultraviolet absorber is ultraviolet absorber UV- 9.

[0050] The preparation method of the modified...

PUM

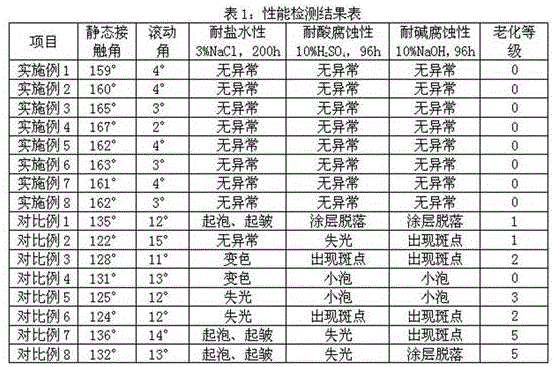

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com