Silicon carbide particle reinforced aluminum matrix composite material for train brake disc and preparation method thereof

A technology of silicon carbide particles and reinforced aluminum base, applied in the direction of brake discs, brake types, brake components, etc., can solve the problem of poor heat resistance and toughness, easy agglomeration of silicon carbide particles, and phase of silicon carbide particles and aluminum alloys Capacitance is not good and other problems, to achieve a strong anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0027] Implementation 1-5: Prepare 1-5# alloys in the table.

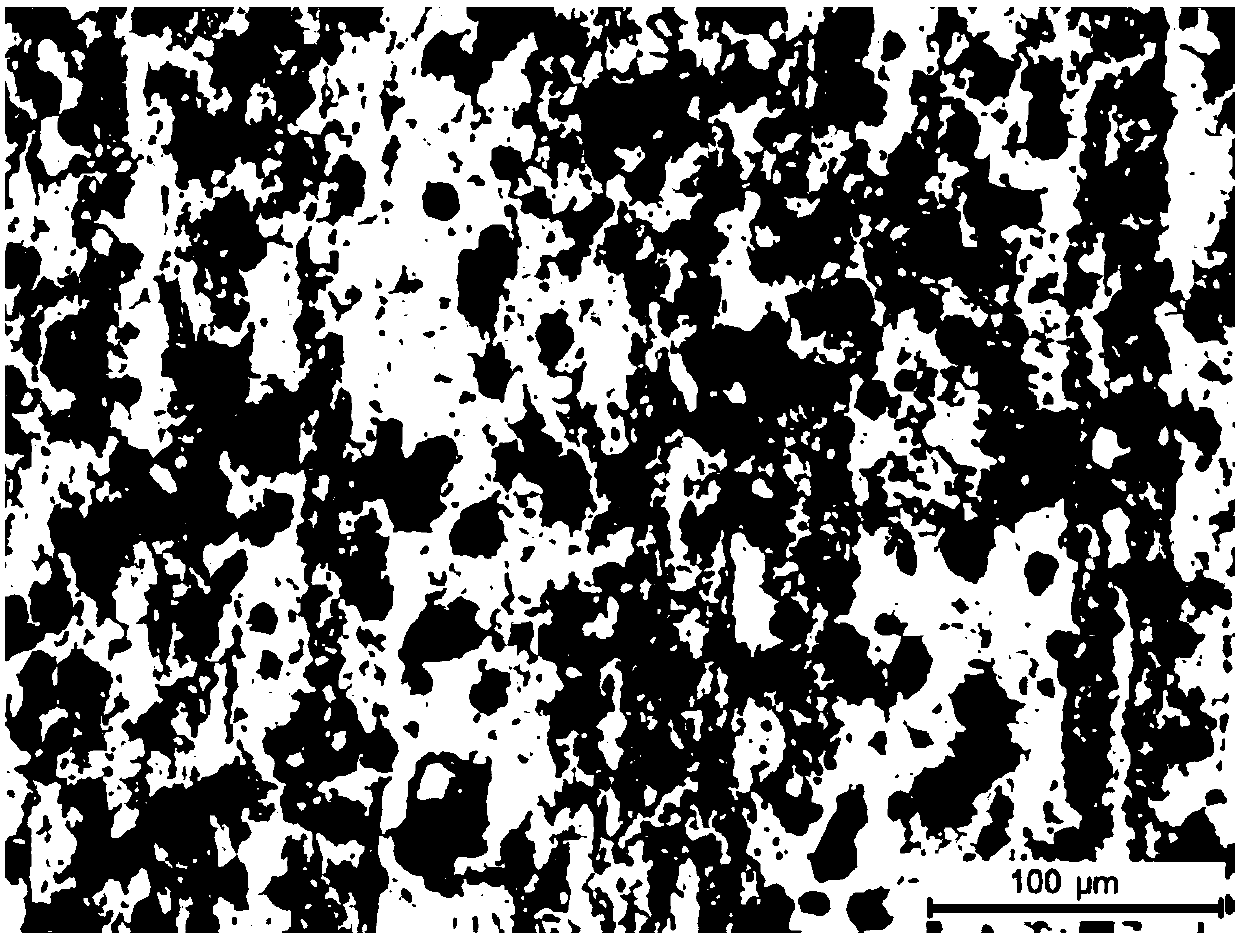

[0028] First, the Mg-SiC alloy was prepared semi-solid under vacuum. Melt the magnesium ingot in a vacuum environment. After the magnesium is completely melted, mix 5-10 μm SiC particles into the liquid magnesium matrix. Before adding the silicon carbide particles, start to stir the liquid magnesium slurry. The stirring cannot be stopped during the adding process, and the stirring process needs to be normalized. Stirring and reverse stirring are carried out alternately to ensure that the silicon carbide particles are evenly dispersed and distributed. After the silicon carbide is mixed, the heating is stopped, poured into the iron mold, and demoulded after cooling.

[0029] Afterwards, the aluminum-based composite material is melted in a resistance crucible furnace at a melting temperature of 800°C. After pure aluminum is melted, first add Al-Si, Al-Zr, Al-Sc intermediate alloys, then mix (10-25μm) SiC particles in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com