Concentrate supplement for milk goats as well as preparation method and application thereof

A concentrate supplement, dairy goat technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of affecting rumen microbial fermentation, destroying the rumen environment, reducing the pH value of the rumen, etc., to improve the daily milk production, ensure Normal function, the effect of increasing fat and protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

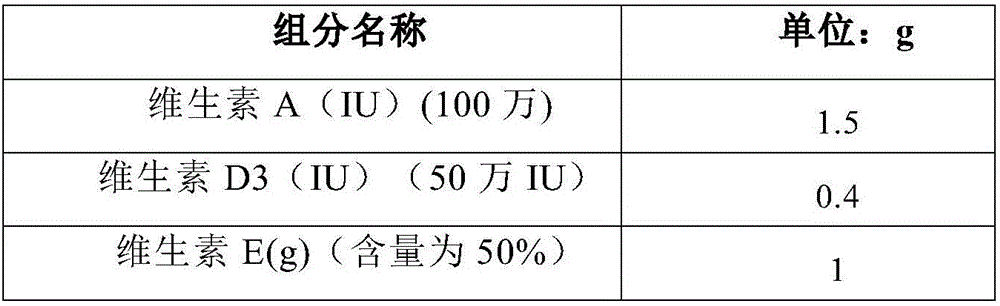

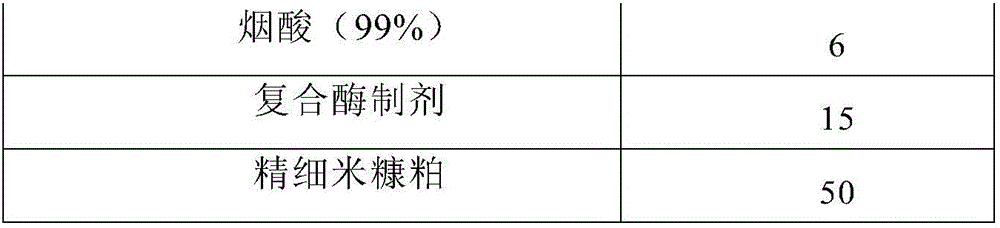

[0030] The following raw materials were weighed: 10g of rice bran, 45g of corn, 12.42g of soybean meal, 9g of cotton meal, 2g of sprayed corn husk, 5g of soybean husk, 11.22g of corn dry distillers grains, 1g of rumen-passed fat, 0.2g of ruminant yeast, Stone powder 1.82g, baking soda 1g, sodium chloride 0.5g, magnesium oxide 0.3g, antifungal agent 0.04g, montmorillonite 0.15g, cow music 0.02g, trace element additive 0.3g, multivitamin 0.03g. Among them, the trace element additive is composed of the composition in Table 1, and the multivitamin is composed of the composition in Table 2.

[0031] Table 1 Trace element additive formula table

[0032] component name Unit: g Copper Sulfate Pentahydrate (98.5%) 1.5 Ferrous sulfate monohydrate (98.5%) 8 Zinc Sulfate Monohydrate (98%) 10 Manganese sulfate monohydrate (98.5%) 8 Magnesium Sulfate Monohydrate (98.5%) 8 Calcium Iodate (5%) 0.7 Cobalt Chloride (1%) 0.6 Sodium Seleni...

Embodiment 2

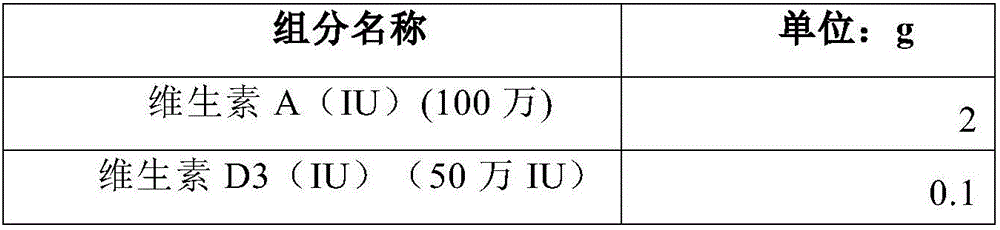

[0038] Weigh the following raw materials: 12g of rice bran, 43g of corn, 12.42g of soybean meal, 8g of cotton meal, 2g of sprayed corn husk, 6g of soybean husk, 11.22g of corn dry distiller's grain, 1g of rumen-passed fat, and 0.2g of ruminant yeast , 1.82g stone powder, 1g baking soda, 0.6g sodium chloride, 0.2g magnesium oxide, 0.04g antifungal agent, 0.15g montmorillonite, 0.02g milk milk, 0.3g trace element additive, 0.03g multivitamin.

[0039] Wherein the trace element additive is composed of the Table 1 distribution in Example 1, and the multivitamin is composed of the Table 2 distribution in Example 1.

[0040] Among the above raw materials, the ratio of neutral detergent fiber to starch is 0.51.

[0041] Preparation method: crush corn, and sieve with a double-layer primary cleaning sieve, the upper and lower meshes of the double-layer primary cleaning sieve are 10.0 mm and 3 mm respectively, to obtain corn flour; crush soybean meal to obtain soybean meal powder; Corn...

Embodiment 3

[0043] Weigh the following raw materials: 9g of rice bran, 48g of corn, 13.42g of soybean meal, 8g of cotton meal, 2g of sprayed corn husk, 4g of soybean husk, 10.22g of corn dry distiller's grain, 1g of rumen-passed fat, and 0.2g of ruminant yeast , stone powder 1.82g, baking soda 1g, sodium chloride 0.4g, magnesium oxide 0.4g, antifungal agent (500g) 0.04g, montmorillonite 0.15g, milk cow music 0.02g, trace element additive 0.3g, compound Vitamin 0.03g.

[0044] Wherein the trace element additive is composed of the Table 1 distribution in Example 1, and the multivitamin is composed of the Table 2 distribution in Example 1.

[0045] Among the above raw materials, the ratio of neutral detergent fiber to starch is 0.55.

[0046] Preparation method: crush corn, and sieve with a double-layer primary cleaning sieve, the upper and lower meshes of the double-layer primary cleaning sieve are 10.0 mm and 3 mm respectively, to obtain corn flour; crush soybean meal to obtain soybean me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com