Method for defoaming spent mother liquor in production of aluminum oxide

A technology for decomposing mother liquor and alumina, which is applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of difficult mechanical design, multiple designs, and increased investment in infrastructure, so as to improve the production and operation environment, have obvious defoaming effect, and process The effect of continuous flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

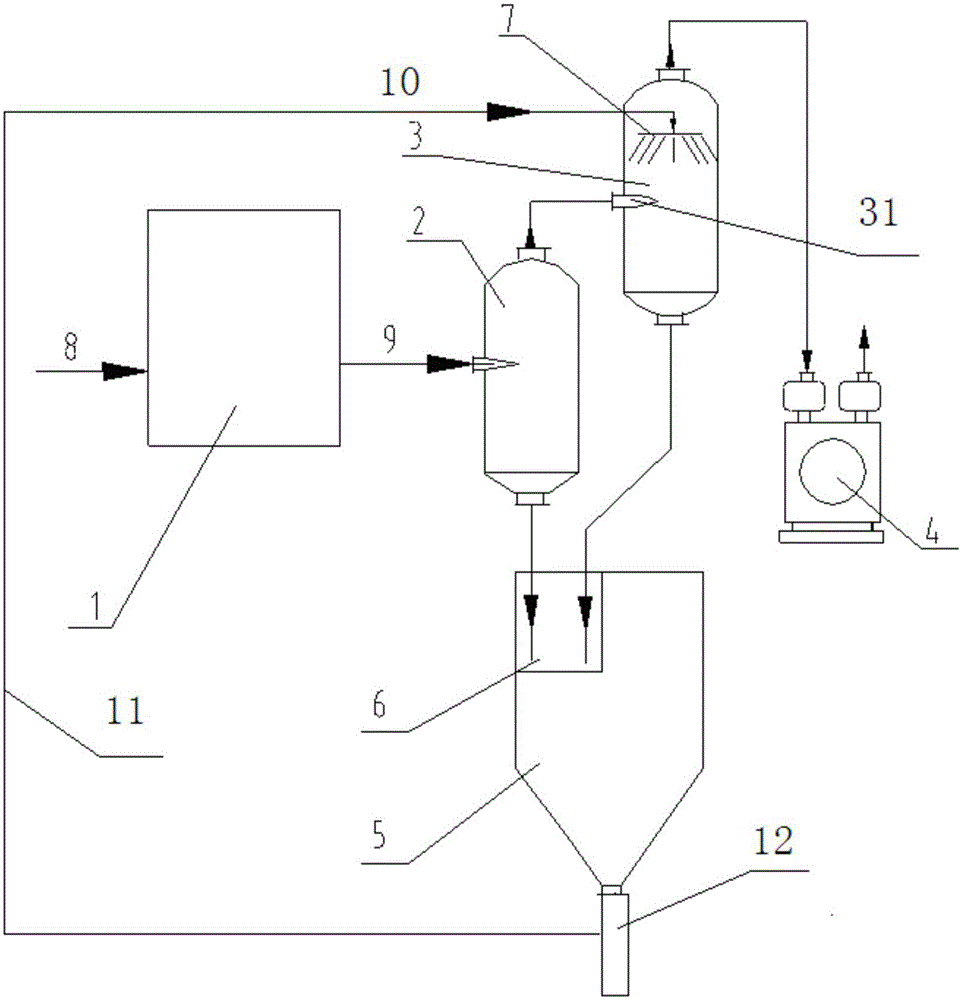

[0017] Such as figure 1 As shown: the aluminum hydroxide slurry 8 is continuously sent to the feed nozzle of the vacuum filter 1, the vacuum filter 1 forms a closed system with the vacuum liquid receiving tank 2 and the gas-liquid separator 3, and the aluminum hydroxide slurry 8 Under the action of the vacuum pump 4, the decomposed mother liquid 9 enters the vacuum liquid receiving tank 2, and enters the gas-liquid separator 3, and the decomposed mother liquid 9 flows to the filtrate tank 5 under the action of gravity, and the filtrate tank 5 has a liquid seal tank 6 inside to act The function of the liquid seal prevents the decomposed mother liquid 9 from being sucked back into the vacuum liquid receiving tank 2 and the gas-liquid separator 3, and the decomposed mother liquid or water 10 returned through the branch pipe 11 is sent to the outlet end of the gas-liquid separator 3 installed The spraying device 7, the reflowed decomposition mother liquor or water 10 sprays foam t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com