Mixed fermentation fiber feed for feeding of laying hens, and preparation method of mixed fermentation fiber feed

A mixed fermentation and feed technology, which is applied in animal feed, animal feed, applications, etc., can solve the problems of low effective utilization of straw and the inability of straw to be used as livestock feed, etc., to improve intestinal health, improve immune function and resistance Disease power, increase the effect of immune nutrition function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

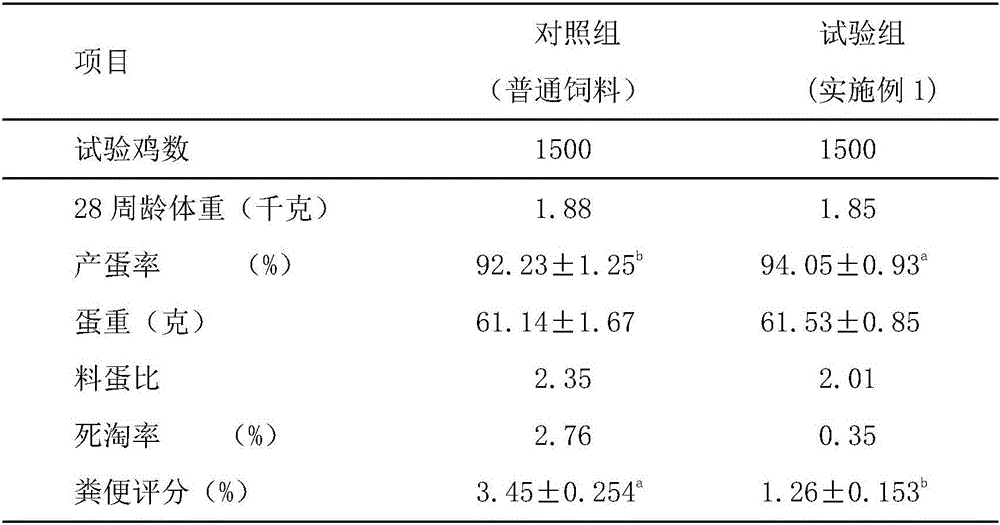

Embodiment 1

[0058] A mixed fermented fiber feed for laying hens is prepared by the following method:

[0059]The mixed fermentation product A of citrus pomace, oat bran, and alfalfa, the mixed fermentation product B of lactic acid bacteria, and the mixed fermentation product C of Bacillus are uniformly mixed according to a mass ratio of 1:2:3 to obtain a mixed fermentation end product. The content of glutathione in the feed product is 36mg / kg.

[0060] Preparation of A: Add the raw material mixture composed of citrus pomace, oat bran, and alfalfa according to the mass ratio of 1:1:3 into a heatable mixer, add water with 50% of the mass of the raw material mixture, and 4% glucose, and mix well After heating to 90°C for 30 minutes, cool the material to 27°C, add mixed yeast seed liquid with 0.3% mass of the raw material mixture, cultivate at 27°C for 56 hours, the stirring speed is 25r / min, and add the raw material mixture after 36 hours of cultivation Mass 0.008% L-cysteine, 0.08% licoric...

Embodiment 2

[0067] A mixed fermented fiber feed for laying hens is prepared by the following method:

[0068] Mix citrus residue, oat bran, and alfalfa yeast mixed fermentation product A, lactic acid bacteria mixed fermentation product B, and Bacillus mixed fermentation product C in a mass ratio of 1:1:2 to obtain a mixed fermentation of citrus residue, oat bran, and alfalfa Final product; the content of glutathione in the feed product is 38mg / kg.

[0069] Preparation of A: Add the raw material mixture composed of citrus pomace, oat bran, and alfalfa in a mass ratio of 1:2:1 to a heatable mixer, add 40% water and 3% glucose by mass of the raw material mixture, and mix well After heating to 80°C for 20 minutes, cool the material to 25°C, add 0.2% mixed yeast seed liquid of the raw material mixture, cultivate at 25°C for 48 hours, and the stirring speed is 20r / min, and add the raw material mixture mass after 30 hours of cultivation 0.005% L-cysteine, 0.1% licorice pulverized grains were dr...

Embodiment 3

[0076] A mixed fermented fiber feed for laying hens is prepared by the following method:

[0077] Mix citrus residue, oat bran, and alfalfa yeast mixed fermentation product A, lactic acid bacteria mixed fermentation product B, and Bacillus mixed fermentation product C according to a mass ratio of 1:3:2 to obtain a mixed fermentation of citrus residue, oat bran, and alfalfa end product. The content of glutathione in the feed product is 37mg / kg.

[0078] Preparation of A: Add the raw material mixture composed of citrus pomace, oat bran, and alfalfa in a mass ratio of 1:1:3 to a heatable mixer, add 60% water and 5% glucose by mass of the raw material mixture, and mix well After heating to 95°C for 30 minutes, cool the material to 30°C, add mixed yeast seed liquid with 0.5% mass of the raw material mixture, cultivate at 30°C for 72 hours, and the stirring speed is 30r / min, and add the raw material mixture after 40 hours of cultivation Mass 0.1% L-cysteine, 0.05% licorice pulveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com