Improved structure of copper metal on the backside of semiconductor element

A backside metal and improved structure technology, applied in semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as unsatisfactory high temperature resistance, damage, and damage to semiconductor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

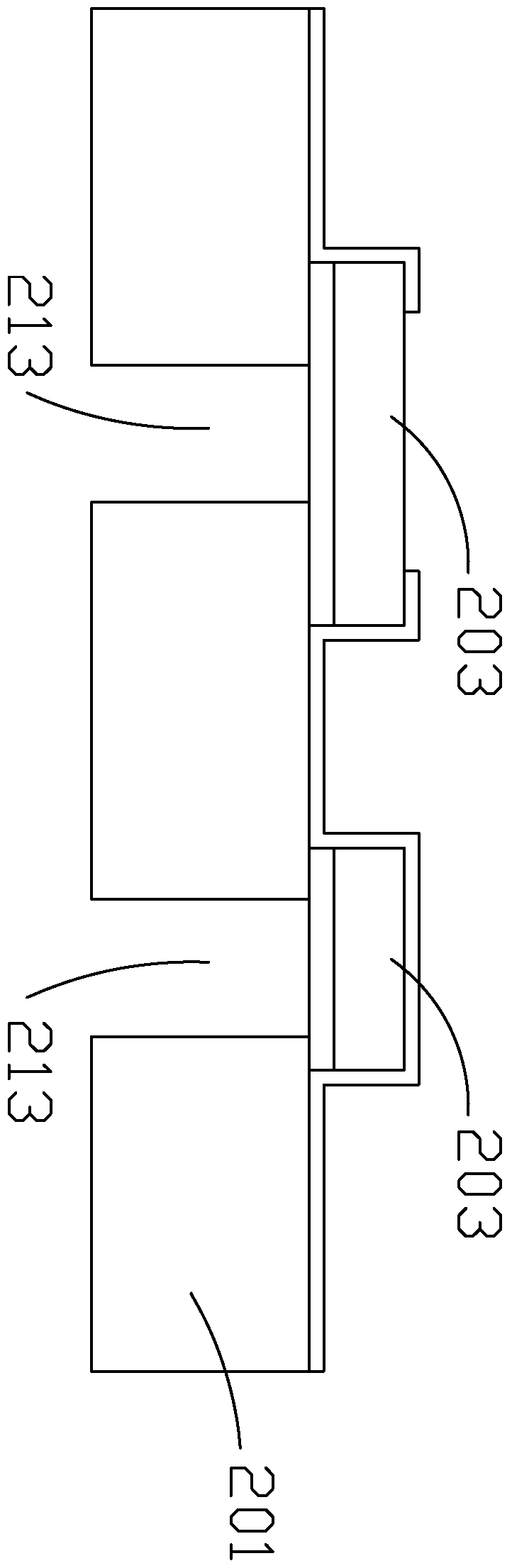

[0033] FIG. 2A is a schematic cross-sectional structure diagram of a specific embodiment of the improved structure of copper metal on the back of the semiconductor device before the back copper metallization of the present invention. It includes a substrate 201 , an active layer 203 and at least one guide hole 213 . The substrate 201 is usually made of semiconductor materials such as gallium arsenide (GaAs), indium phosphide (InP), gallium nitride (GaN) or silicon carbide (SiC). An active layer 203 is disposed on the front side of the substrate 201, and the active layer 203 includes at least one integrated circuit. Since the integrated circuit in the active layer 203 needs a grounding point, the required number of backside vias 213 will be made by etching technology on the back side of the substrate 201, through which the integrated circuit in the active layer 203 can The ground of the is connected to the ground plane of the remote configuration.

[0034]FIG. 2B is a schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com