Damp fast solidification upper blade gum and preparing method thereof

A fast-curing, web-backed adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as poor weather resistance, decreased bond strength, and slow curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

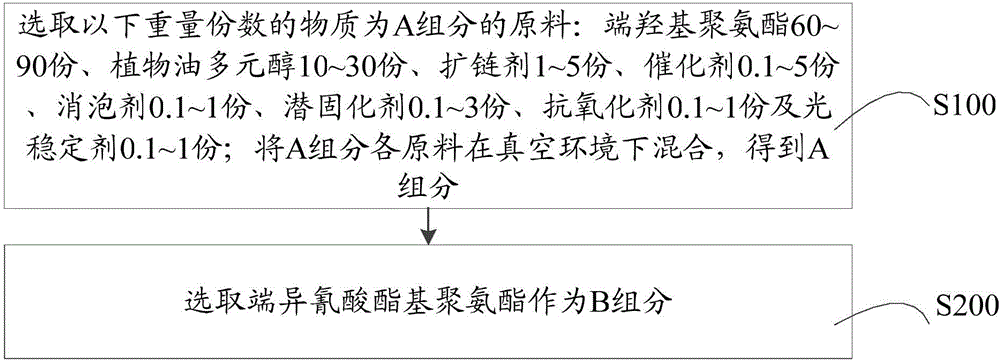

[0066] The preparation step S100 of component A includes: selecting the following materials in parts by weight as the raw materials of component A: 60-90 parts of hydroxyl-terminated polyurethane, 10-30 parts of vegetable oil polyol, 1-5 parts of chain extender, and 0.1-90 parts of catalyst. 5 parts, 0.1 to 1 part of defoamer, 0.1 to 3 parts of latent curing agent, 0.1 to 1 part of antioxidant and 0.1 to 1 part of light stabilizer; mix the raw materials of component A in vacuum environment according to parts by weight, Obtain the A component.

[0067] Preferably, in step S100, the time for mixing the raw materials of component A in a vacuum environment is 0.5 h.

[0068] In one of the embodiments, the structure of the hydroxyl-terminated polyurethane is as follows:

[0069] (OH)n-R 2 -OOC-NH-R 1 -NH-COO-R 2 -(OH)n, n is 1 or 2;

[0070] It is prepared by the following steps: (OH)n-R 2 -OH is heated to 100-120°C, and stirred under vacuum for 1-2 hours; then cooled to 75-8...

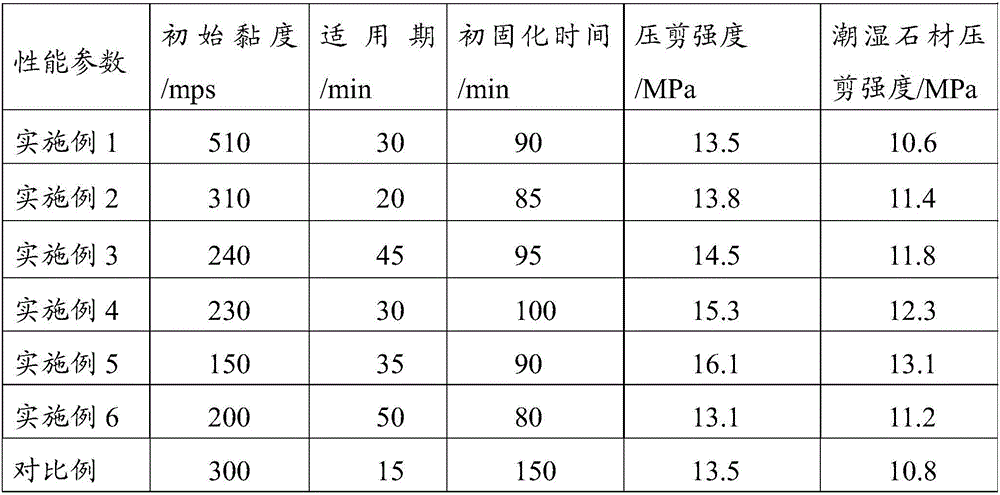

Embodiment 1

[0081] The moisture fast curing back mesh adhesive of embodiment 1 includes A component and B component.

[0082] In parts by weight, component A includes: 82 parts of hydroxyl-terminated polyurethane, 10 parts of castor oil, 1 part of chain extender diethylene glycol, 0.5 part of organic bismuth catalyst, 0.5 part of defoamer BYK-141, latent 0.6 parts of curing agent trimethylacetaldehyde-triethylenediamine, 0.2 parts of antioxidant 1010, 0.2 parts of light stabilizer UV-327, 5 parts of ethyl acetate as the first solvent. Wherein, the hydroxyl-terminated polyurethane is formed by polyurethane polymerization of polyether polyol DL-2000D and polyisocyanate PAPI, and the hydroxyl value of the hydroxyl-terminated polyurethane is 100 mg / g.

[0083] The preparation step of component A: mix the raw materials of component A in vacuum environment for 0.5h according to parts by weight to obtain component A.

[0084] In parts by weight, component B includes: 90 parts of isocyanate-term...

Embodiment 2

[0088] The moisture fast curing back mesh adhesive of embodiment 2 includes A component and B component.

[0089] In parts by weight, component A includes: Component A includes: 82 parts of hydroxyl-terminated polyurethane, 10 parts of soybean oil polyol, 1 part of chain extender MOCA, 0.5 part of organic zinc catalyst, and 0.5 part of defoamer BYK-066N , 0.6 parts of latent curing agent trimethylacetaldehyde-ethylenediamine, 0.2 parts of antioxidant 264, 0.2 parts of light stabilizer UV-326, 5 parts of the first solvent ethyl acetate. Wherein, the hydroxyl-terminated polyurethane is formed by polyurethane polymerization of polyether polyol DL-1000D and polyisocyanate MDI, and the hydroxyl value of the hydroxyl-terminated polyurethane is 100 mg / g.

[0090] The preparation step of component A: mix the raw materials of component A in vacuum environment for 0.5h according to parts by weight to obtain component A.

[0091] In parts by weight, component B includes: 70 parts of iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com