Method for preparing titanium dioxide/active carbon electrode material from waste cotton textiles

A technology for preparing activated carbon and electrode materials, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex processing and brittle carbon fiber clusters, and achieve simple operation, low corrosiveness and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

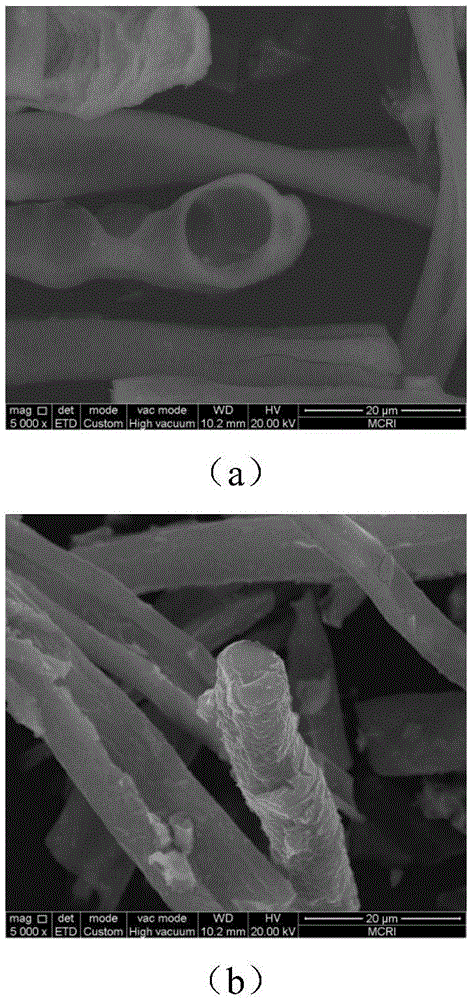

[0053] (1) Raw material pretreatment: the waste cotton textiles were washed, dried in a constant temperature drying oven at 70°C for 24 hours, cut to 2cm×1.5cm, and sealed for future use.

[0054] (2) Preparation of carbonized material: Weigh 10g of rags and place them in a tubular resistance furnace. Under a nitrogen atmosphere, the temperature is programmed at a rate of 3°C / min, raised to 450°C, kept for 40min, carbonized, and ground after cooling into powder to obtain carbonized material.

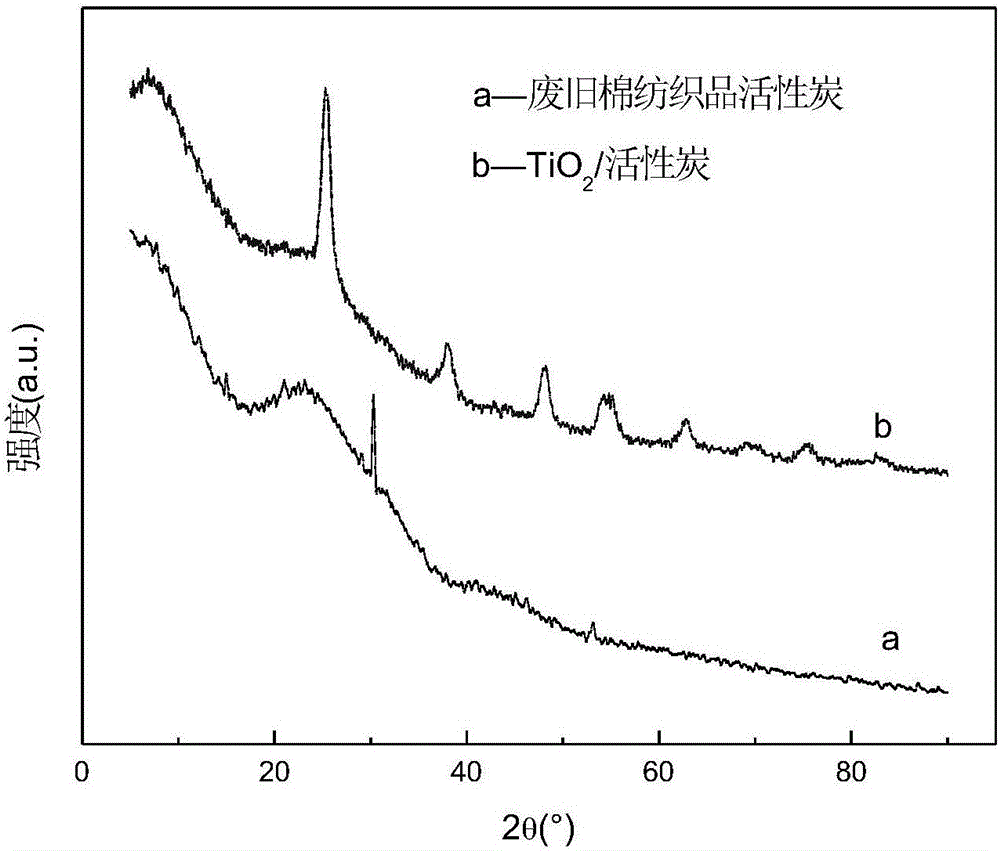

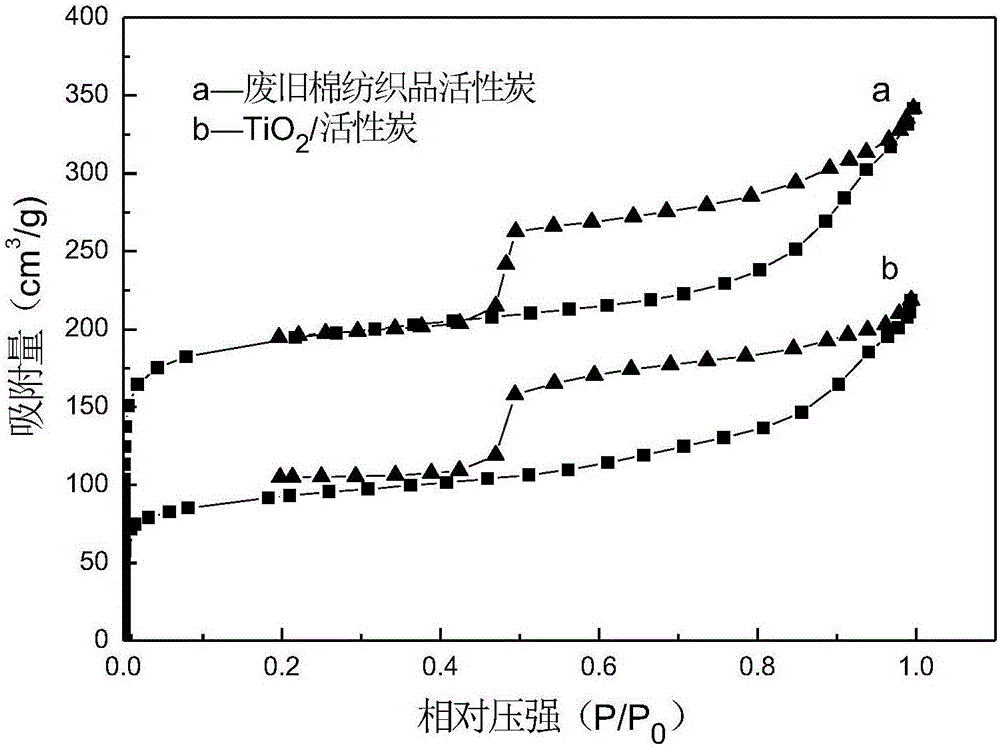

[0055] (3) Preparation of activated carbon: carbonized material and KOH were impregnated at room temperature for 8 hours at a mass ratio of 1:2, dried and placed in a tubular resistance furnace. Keep it at 800°C for 70 minutes, then take it out after cooling down. In order to remove the residual activator, grind it and wash it with 0.1mol / L hydrochloric acid, boil it with ultrapure water until the conductivity is less than 10μS / cm, and dry it to constant weight. It is cotton textile act...

Embodiment 2

[0058] (1) Raw material pretreatment: the waste cotton textiles were washed, dried in a 90°C constant temperature drying oven for 22 hours, cut to 2cm×1.5cm, and sealed for future use.

[0059] (2) Preparation of carbonized material: Weigh rags and place them in a tubular resistance furnace. Under a nitrogen atmosphere, the temperature is programmed at a rate of 4°C / min, raised to 400°C, and kept for 60 minutes for carbonization treatment. After cooling down, grind into Powder, in carbonized material.

[0060] (3) Preparation of activated carbon: carbonized material and KOH were impregnated at room temperature for 24 hours at a mass ratio of 1:0.5, dried and placed in a tubular resistance furnace. Keep it at 900°C for 40 minutes, then take it out after cooling down. In order to remove the residual activator, grind it and wash it with 0.15mol / L hydrochloric acid, boil it with ultrapure water until the conductivity is less than 10μS / cm, and dry it to constant weight. It is cott...

Embodiment 3

[0063] (1) Raw material pretreatment: the waste cotton textiles were washed, dried in a constant temperature drying oven at 80°C for 20 hours, cut to 2cm×1.5cm, and sealed for future use.

[0064] (2) Preparation of carbonized material: Weigh the raw material and place it in a tubular resistance furnace. Under a nitrogen atmosphere, the temperature is programmed at a rate of 5°C / min, raised to 350°C, kept for 50min, carbonized, and ground into powder after cooling down. Get carbonized material.

[0065] (3) Preparation of activated carbon: carbonized material and KOH were impregnated at room temperature for 16 hours at a mass ratio of 1:1, dried and then placed in a tubular resistance furnace. Keep it at 700°C for 50 minutes, then take it out after cooling down. In order to remove the residual activator, grind it and wash it with 0.12mol / L hydrochloric acid, boil it with ultrapure water until the conductivity is less than 10μS / cm, and dry it to constant weight. It is cotton t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com