Calcite phase spherical porous calcium carbonate granule and preparation method thereof

A technology of porous calcium carbonate and calcite, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve problems such as poor dispersion, not suitable for biomedical applications, and serious powder agglomeration , to achieve the effects of mild preparation process, low energy consumption, promotion of attachment and proliferation, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

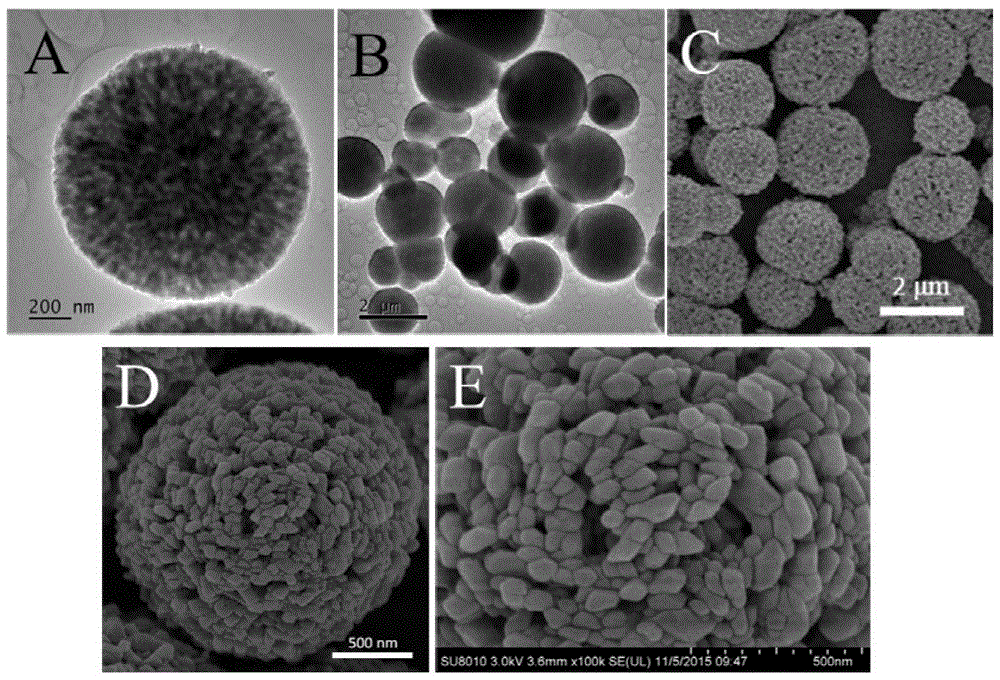

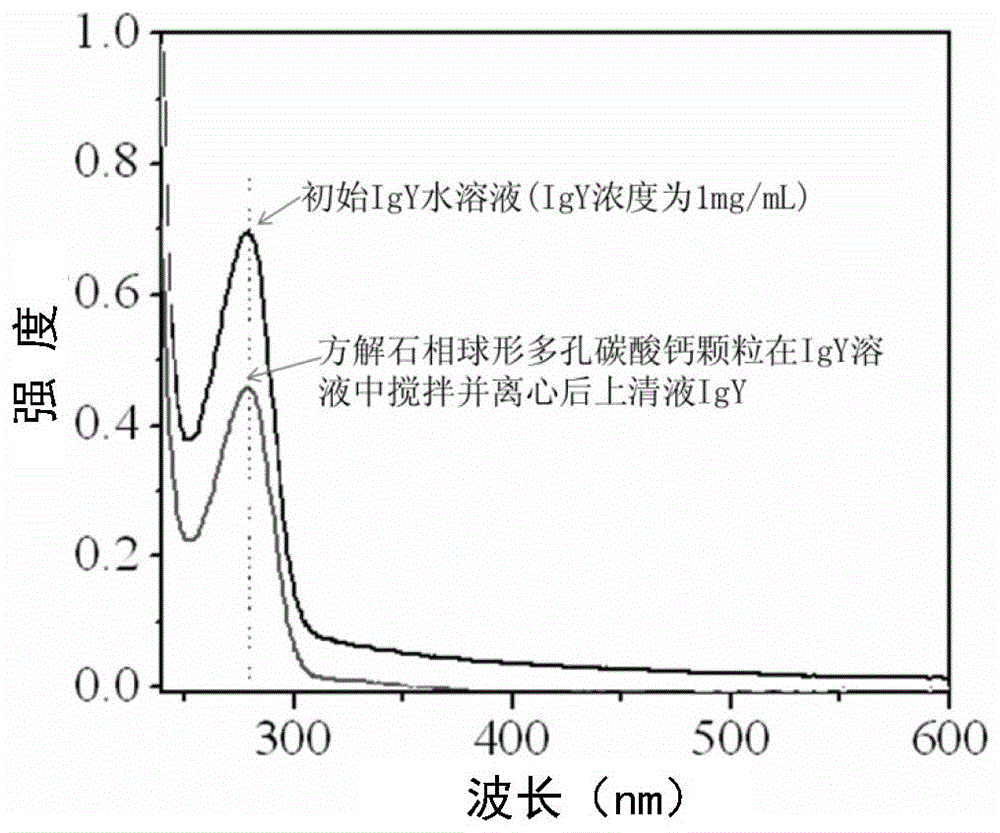

[0048] 10g CaCl 2 2H 2 O was dissolved in 400mL ethanol, and the above-mentioned mixed solution A was put into a glass jar. Put the ammonium bicarbonate powder into another 300mL glass jar. The above reaction glass containers were placed together in a sealed desiccator at 30° C. for 168 h, and a white precipitate was formed in the transparent solution. The precipitate was collected by centrifugation and dried under vacuum at 25°C to obtain a white powder. Then the obtained white powder was re-immersed in 40 mL of water / ethanol mixed solution F (containing 0.8 mL of water), left standing at 30° C. for 168 h, centrifuged, and dried to obtain calcite-phase spherical porous calcium carbonate particles. Such as figure 1 As shown in the TEM (A, B) and SEM (C, D, E) images, the material is composed of a pore structure obtained by the accumulation of rhombohedral calcium carbonate grains, spherical and round, with high crystallinity and three-dimensional penetration of the pores ...

Embodiment 2

[0050] 3.2g CaCl 2 2H 2 O was dissolved in 400mL ethanol, and the above-mentioned mixed solution A was put into a glass jar. Put the ammonium bicarbonate powder into another 300mL glass jar. The above reaction glass containers were placed together in a sealed desiccator at 30° C. for 72 hours, and a white precipitate was formed in a transparent solution. The precipitate was collected by centrifugation and dried under vacuum at 25°C to obtain a white powder. Then the obtained white powder was re-immersed in 40 mL of water / ethanol mixed solution F (containing 0.8 mL of water), left standing at 30° C. for 168 h, centrifuged and dried to obtain calcite-phase spherical porous calcium carbonate particles. The obtained material is composed of a pore structure obtained by stacking calcite-phase calcium carbonate crystal grains, is spherical and round, and has a particle diameter of less than 3 μm, and the particle diameter of the calcite-phase calcium carbonate crystal grains is 50...

Embodiment 3

[0052] 16g CaCl 2 2H 2O was dissolved in 400 mL of ethanol, and the above mixed solution A was filled into a glass jar. Put the ammonium bicarbonate powder into another 300mL glass jar. The above reaction glass containers were placed together in a sealed desiccator at 30° C. for 240 h, and a white precipitate was formed in the transparent solution. The precipitate was collected by centrifugation and dried under vacuum at 25°C to obtain a white powder. Then the obtained white powder was re-immersed in 40 mL of water / ethanol mixed solution F (containing 2 mL of water), left standing at 30° C. for 48 h, centrifuged, and dried to obtain calcite-phase spherical porous calcium carbonate particles. The obtained material is composed of a pore structure obtained by stacking calcite-phase calcium carbonate crystal grains, is spherical and round, and has a particle diameter of less than 3 μm, and the particle diameter of the calcite-phase calcium carbonate crystal grains is 50-200 nm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com