Preparation method of up-conversion luminescence EVA photovoltaic film

A light-emitting, adhesive film technology, applied in the direction of photovoltaic power generation, film/sheet adhesives, adhesives, etc., can solve the problems of output power reduction, reduction of power generation power, and increase of battery operating temperature, etc., to achieve output power increase , lower temperature, better compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

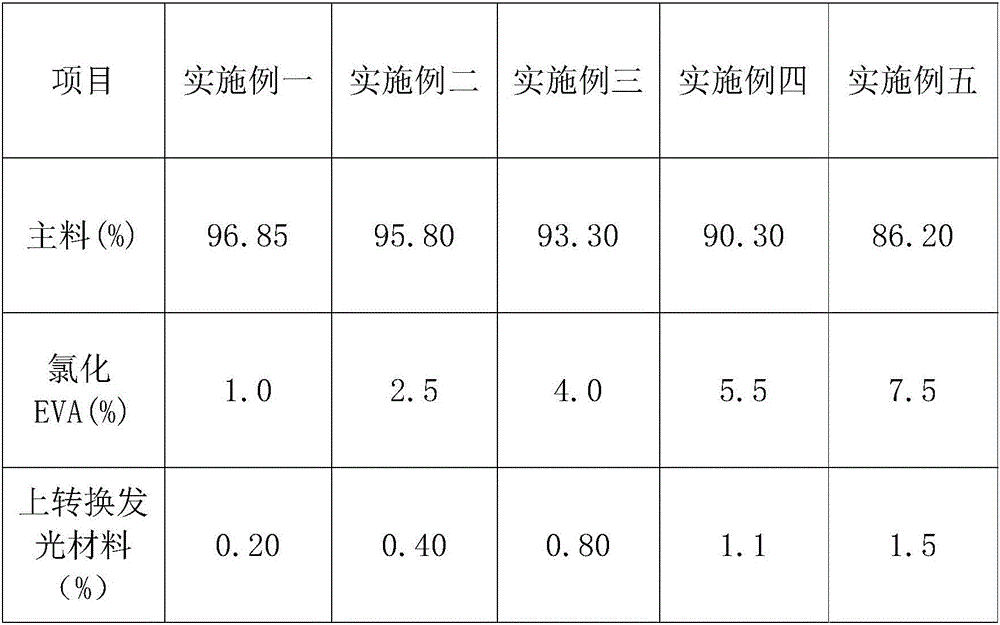

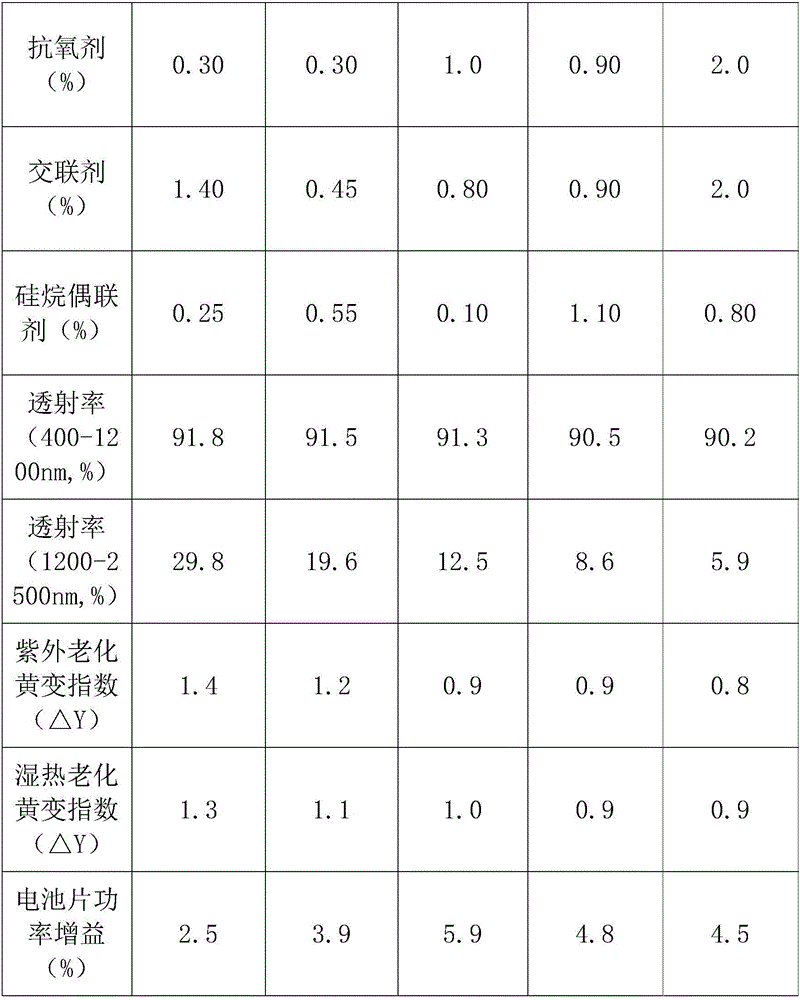

Examples

Embodiment 3

[0023] Example 3 is a preferred embodiment.

[0024] The antioxidant in Examples 1-5 includes a primary antioxidant and a secondary antioxidant. The mass ratio of the primary antioxidant to the secondary antioxidant is 8:1, and the primary antioxidant is β-(3,5- Di-tert-butyl-4-hydroxyphenyl) stearyl propionate; auxiliary antioxidant is tris(4-nonylphenol) phosphite and / or tris(2,4-di-tert-butyl phosphite) Phenyl) ester, preferably a combination of tris(4-nonylphenol) phosphite and tris(2,4-di-tert-butylphenyl) phosphite, the auxiliary antioxidant in Examples 1-5 The compound used is tris(4-nonylphenol) phosphite and tris(2,4-di-tert-butylphenyl) phosphite.

[0025] The cross-linking agent in the present invention includes a cross-linking curing agent and a co-cross-linking agent, and the mass ratio of the cross-linking curing agent to the co-cross-linking agent is 10:1, wherein the cross-linking curing agent includes organic peroxides and / or couples. Nitrogen compounds, organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com