Blue fluorescent material and preparation method thereof

A technology of blue fluorescence and fluorescence emission, applied in the field of fluorescent materials, can solve the problems of insufficient spectrum, poor controllability of preparation methods, and low fluorescence quantum efficiency of gibbsite nano-luminescent materials, and achieves high efficiency, simple operation, Low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

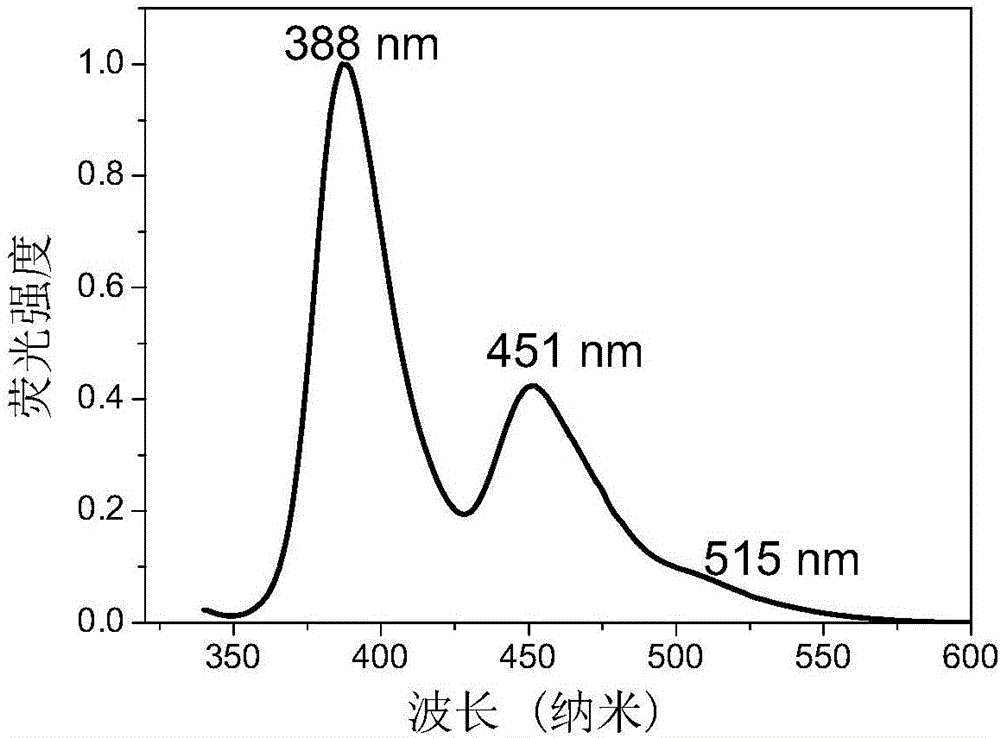

Embodiment 1

[0076] Take an appropriate amount of organoaluminum salt precursor basic aluminum acetate (Al(OH)(Ac) 2 ), fully ground. Weigh 0.5000g-2.0000g of the ground basic aluminum acetate powder.

[0077] Put the weighed basic aluminum acetate powder into the quartz boat, put the quartz boat into the quartz tube, and then put the quartz tube into the heating area of the tube furnace. Connect the exhaust system, check the airtightness of the system after sealing, and set the heating conditions after confirming that the airtightness is good.

[0078] Nitrogen gas was introduced into the quartz tube for 30 minutes to exhaust. After the exhaust was completed, nitrogen gas was continuously injected at a rate of 50 sccm, and the heating program of the tube furnace system was started. The starting temperature is room temperature, and the heating rate is 26°C / min. After the temperature was raised to 290°C, the system was kept at 290°C for 2 hours.

[0079] After the tube furnace system ...

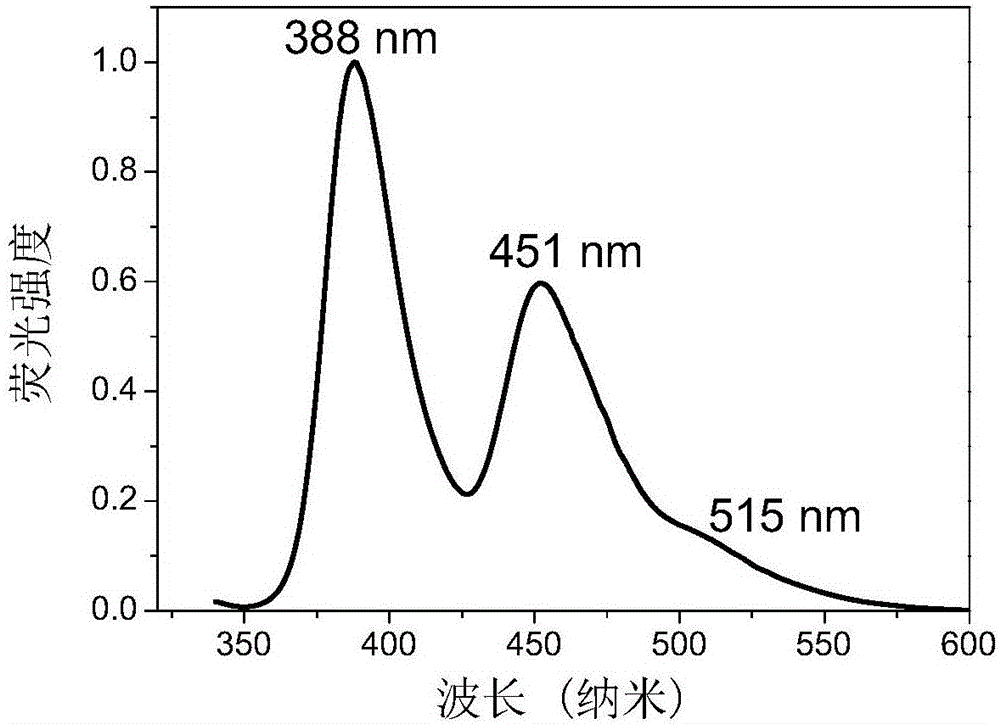

Embodiment 2

[0085] Take an appropriate amount of organoaluminum salt precursor basic aluminum acetate (Al(OH)(Ac) 2 ), fully ground. Weigh 1.25 g of ground basic aluminum acetate powder.

[0086] Put the weighed basic aluminum acetate powder into the quartz boat, put the quartz boat into the quartz tube, and then put the quartz tube into the heating area of the tube furnace. Connect the exhaust system, check the airtightness of the system after sealing, and set the heating conditions after confirming that the airtightness is good.

[0087] Nitrogen gas was introduced into the quartz tube for 30 minutes to exhaust. After the exhaust was completed, nitrogen gas was continuously injected at a rate of 50 sccm, and the heating program of the tube furnace system was started. The initial temperature is room temperature, and the heating rate is 30°C / min. After heating up to 300°C, the system was kept at 300°C for 2.5h.

[0088] After the tube furnace system is kept warm and automatically st...

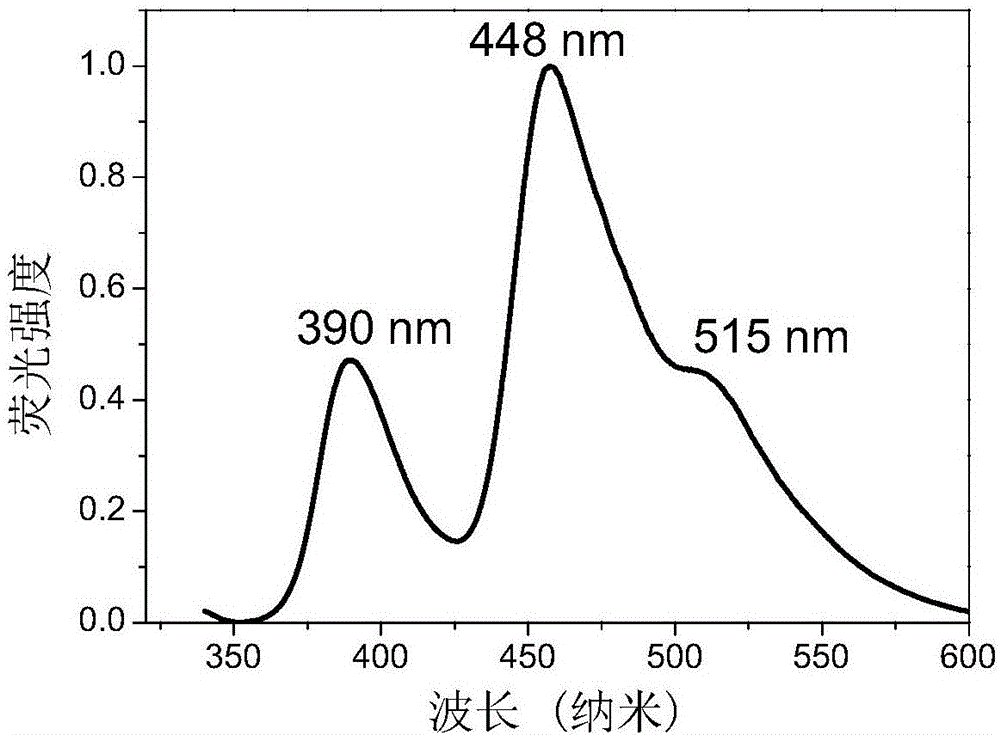

Embodiment 3

[0093] Take an appropriate amount of organoaluminum salt precursor basic aluminum acetate (Al(OH)(Ac) 2 ), fully ground. Weigh 1.25 g of the ground basic aluminum acetate powder.

[0094] Put the weighed basic aluminum acetate powder into the quartz boat, put the quartz boat into the quartz tube, and then put the quartz tube into the heating area of the tube furnace. Connect the exhaust system, check the airtightness of the system after sealing, and set the heating conditions after confirming that the airtightness is good.

[0095] Nitrogen gas was introduced into the quartz tube for 30 minutes to exhaust. After the exhaust was completed, nitrogen gas was continuously injected at a rate of 100 sccm, and the heating program of the tube furnace system was started. The starting temperature is room temperature, and the heating rate is 32°C / min. After the temperature was raised to 320°C, the system was kept at 320°C for 2.5 hours.

[0096] After the heat preservation of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminescence spectrum | aaaaa | aaaaa |

| Luminescence spectrum | aaaaa | aaaaa |

| Luminescence spectrum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com